KDM specializes in aluminum sheet metal fabrication for over 20 years. The custom aluminum sheet can produce specific parts or new equipment that match your needs.

- Ideal for jobs that need durability and strength

- Cost-effective solution and versatile

- Highly machinable, weldable, and weather-resistant

- Creates complex shapes of parts and components

What is Aluminium Sheet Metal Fabrication

The aluminum sheet metal fabrication is a production process of aluminum sheets. The aluminum is corrosion-resistant and lightweight that makes them popular in the metal manufacturing process. These processes can create a precise part, component, or end product. Most industrial sectors are utilizing aluminum sheet metal fabrication to manufacture any finish products.

KDM has rich experience in aluminum sheet metal fabrication. It allows us to manufacture different aluminum products such as enclosures, cans, cars, airplanes, appliances, and many more. We have professional engineers to process the aluminum sheet metal fabrication, from cutting, forming to finishing.

If you need custom aluminum sheet fabrication services, please contact us directly.

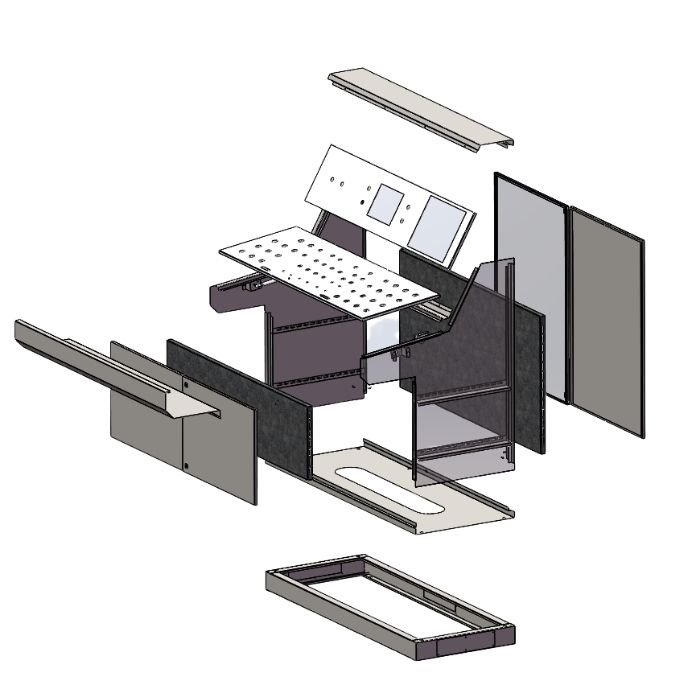

KDM Aluminum Sheet Metal Fabrication

KDM is skilled in powder-coated aluminum sheet metal fabrication. Commonly are industrial manipulative, machine enclosure, brackets, and many more.

KDM provides various laser-cutting fabrication of aluminum for different industries. It is available in numerous finishes like powder-coated, brushed, or natural.

KDM provides CNC machined aluminum such as panels, heat sinks, enclosures, and many others. It is available in many surface treatments like powder coated.

KDM welding aluminum structural sheet metal box is fabricated according to your preference (material, size, processing content, thickness, etc.)

The aluminum deep drawn bending fabrication is ideal for furniture, machinery, automobile, and electronic industry.

KDM provides high-quality aluminum forming sheet metal fabrication. It is available in a custom color, dimensions, and other specifications.

Aluminum Sheet Metal Parts (5)

Why KDM Aluminium Sheet Metal Fabrication

Because of its elasticity and malleability characteristics, aluminum is often used in many industries. Aluminum sheet metal is easy to shape and bent.

The aluminum sheet metals are popular for their corrosion and rust-resistant. For longer life, KDM is capable of wet painting, metal finishing, powder coating, etc.

KDM aluminum sheet metal fabrication is a cost-effective and flexible solution to plastic fabrication problems. Aluminum provides more strength and affordability than plastics.

The aluminum metal sheets are lightweight. Therefore, they are an excellent solution for different project fabrication that requires versatility.

Aluminium Sheet Metal Fabrication Material

KDM has decades of experience in fabricating different kinds of aluminum. Our team works with different alloys, such as:

- 3003-H14 and 3003 Alloy: These alloys are low-cost, still formable, corrosion-resistant, and weldable. It is used for drawing, spinning, and stamping products and parts. Also, for producing chemical equipment, cooking utensils, storage tanks, mailboxes, and many more.

- Alloy 5052-H32: These alloys offer good formability, corrosion-resistant, and weldability. They are widely utilized for food processing equipment, pressure vessels, electronic chassis, and aircraft components. The alloy 5052-H32 is suitable to produce parts and components that require good formability and strength.

- Alloy 6061-T6, 6061-T4, 6061: These alloys are less weldable and formable compared to other grades. It is widely used for frames, structural components, machine parts, electric fittings, hinge pins, etc. 6061 series of alloys are suitable for heavy-duty structures that need corrosion resistance. These alloys are easily formed and cold work in annealed conditions.

KDM provides various alloy grades for aluminum sheet metal fabrication to meet your requirements. Contact us for more information.

KDM Aluminium Sheet Metal Fabrication for Various Industries

Aluminums have flexible nature and are cost-effective. It also offers a wide range of grades and options. Their excellent properties make them ideal in different industries. For instance, the aerospace industry usually utilizes aluminum due to its high-strength property. Moreover, aluminiums are corrosion resistant which makes them popular in the marine industry.

KDM specializes in aluminium sheet fabrication for various industries, such as:

- Medical

- Defense/Military

- Energy

- Aerospace/Avionics

- Custom projects

- Electronic enclosures

Contact us for your aluminium sheet metal fabrication needs!

Aluminium Sheet Metal Fabrication Process

There are many processes in the fabrication of aluminium sheet metal. The process allows the aluminium sheet to form into a three-dimensional piece or component. KDM aluminium sheet metal fabrication is the best solution to produce more complex, large parts or systems.

Cutting: There are two types of cutting: shear and non-shear. Shear cutting is widely utilized in nonindustrial applications. Non-shear cutting is employed in most industrial applications.

Forming: It is a process to reshape the aluminum without cutting it. The forming process includes bending, stamping, extruding, etc.

Welding and Brazing: This process means to melt and join metals together. It requires melting materials.

Adhesives and Riveting: It is a process of joining that does not need melting materials.

Finishing: Components, parts, or end products involve different finishing like deburring, sandblasting, coating, or annealing.

Choose KDM to Custom Aluminum Sheet Metal Fabrication Needs

KDM provides the best solution for aluminium sheet metal fabrication.

Being a leading manufacturer, we are able to meet the most stringent requirements of every clients.

We are using advanced manufacturing equipment to work with aluminium sheet metal fabrication.

KDM Aluminum Sheet Metal Fabrication

- Wide range of aluminum alloy grades

- Non-magnetic

- Lightweight

- Strong

- Versatile

- Corrosion-resistant

- Billet Aluminum Plate

- Aluminum Front Panel

- Aluminum Fuel Tank Fabrication

- Aluminum Pressure Vessels

- Aluminum Chemical Equipment

- Aluminum Structural Component

Aluminum Sheet Metal Fabrication for Various Industries

KDM specializes in aluminum sheet fabrication for medical industry. Aluminum sheets are often utilized for endoscopic, orthopedic, and many more.

The aluminum sheets fabrication is common in the aerospace industry. Aluminum sheets have high-strength properties, ideal to produce aerospace fittings and devices.

KDM provides custom aluminum sheet fabrication for the marine industry. Aluminum sheets can withstand wet or water environments.

KDM can produce anything using aluminum sheet fabrication for custom projects. We can handle plan-and-specs projects and complex design projects in any industry.

Why KDM is Trusted By Over 1000 Global Clients

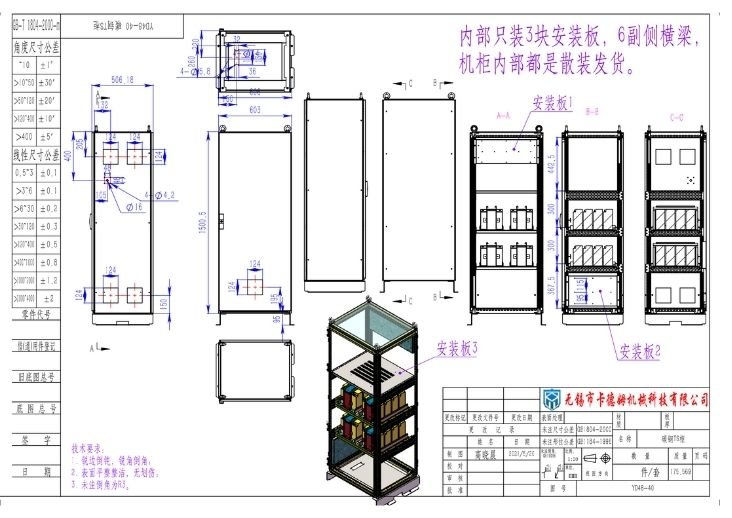

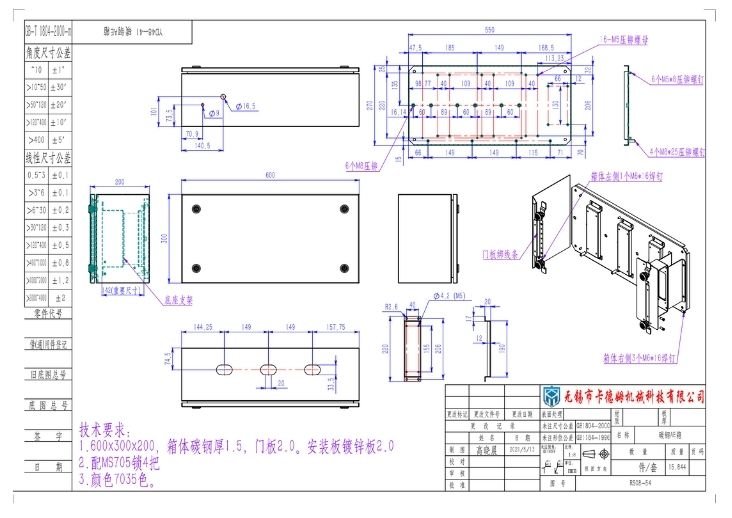

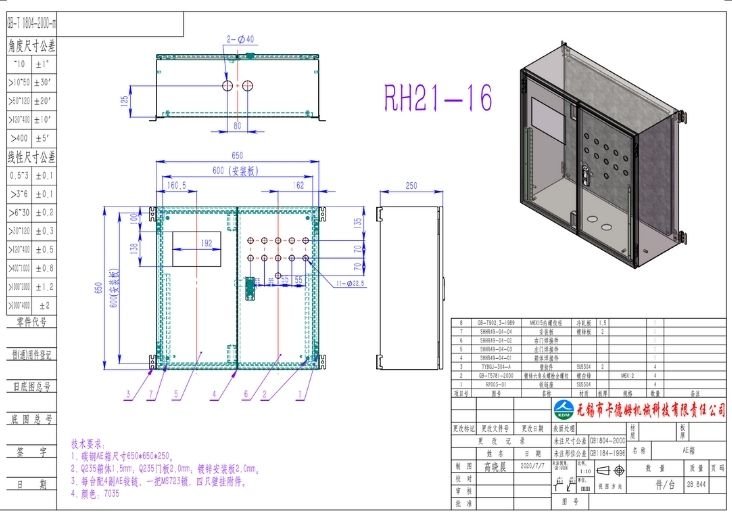

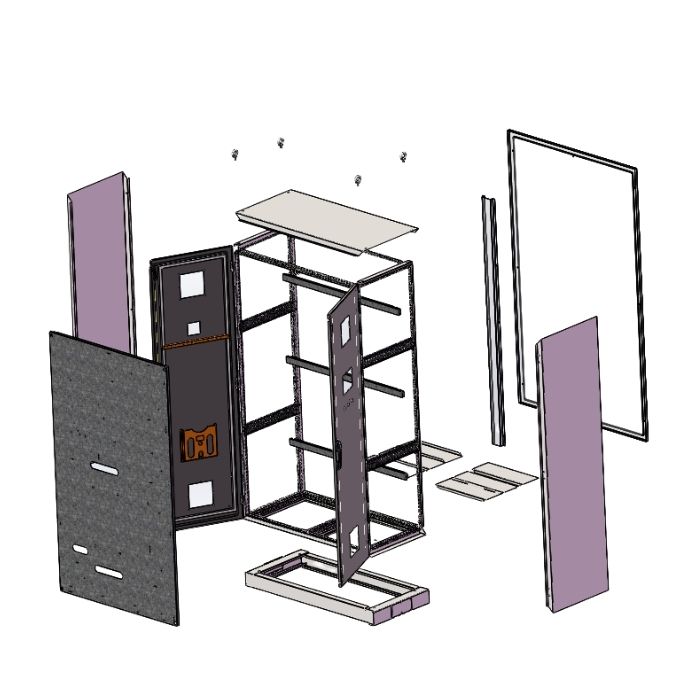

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure