KDM is a trusted copper sheet metal fabricator in China. We offer excellent fabrications services and copper sheet metal products according to your requirements.

- Versatile, durable material copper sheet metal

- Corrosion resistance and high malleable

- Precisely manufacture ed on your request

- Cost-effective products and services

Copper Sheet Metal Fabrication

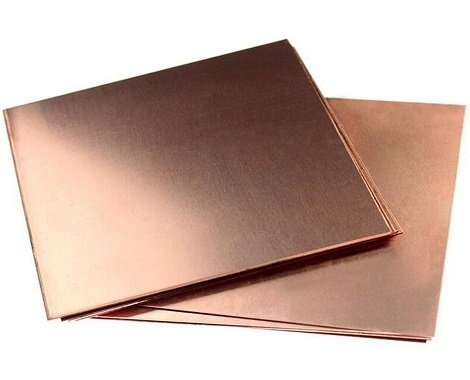

Copper Sheet Metal Fabrication is an effective process of using copper to produced various components. Copper sheet metal is a type of soft metal with a red-orange surface and metallic luster. It is also known as electrolytic tough pitch copper.

Due to its slow corrosion rate, high thermal, electrical conductivity, and good ductility, it is the most commonly used material in many applications. Copper sheet metal applications include anodes, plumbing fitting, welding fixtures, spark plugs, terminals, and other electrical and electronic parts.

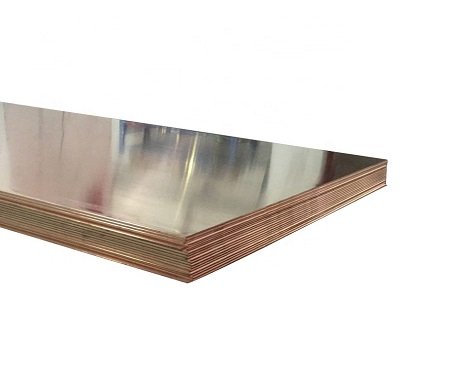

KDM is a professional sheet metal manufacturing company in China. We can complete your copper fabrication needs professionally. Our team has profound experience in laser cutting, forming, stamping, welding, sheet metal fabrication, and precision machining. We work with various copper grades with 0.6-150mm thicknesses and 10-2500mm width. With technical knowledge and advanced machines, KDM guarantee your copper fabrication done efficiently and economically. Message us now!

KDM Copper Sheet Metal Series

High Precision Stamping Copper Sheet Metal is manufactured with hot-dipped galvanized treatment. Due to its excellent mechanical properties and corrosion-resistant features, it is used in automotive, electronic, home appliances, etc.

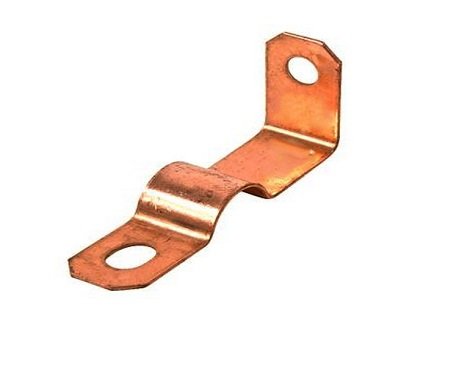

Tollers Bracket Parts Copper Sheet Metal is manufactured from 0.1-4.0mm thickness copper. It is ideal for plating, anodizing, polishing coatings. It can be used in construction, electronics, etc.

Copper Sheet Metal Parts are made from oxygen-free copper grade with 0.1-3mm thickness. This can be utilized in medical, housing, machinery, automotive applications, etc.

KDM is made from C11000,C12000, C36000 copper grade, etc. It is available in various spinning thicknesses. You can get it anodizing and powder coating surface treatment. This product is fully checked and inspected before delivery.

Sheet Metal Riveting Electrical Contacts is a durable small stamping part. It has a zinc plating or a nickel plating finish. This is applied in architecture, industry, furniture applications.

High precision sheet metal stamping parts are manufactured from bending, welding, riveting, laser cutting processes, etc. It has sufficient strength to be molded and is durable enough to not break.

Copper Sheet Metal By Finishes (6)

KDM Copper Sheet Metal Services (4)

KDM Copper Sheet Metal Advantages

KDM copper sheet metal properties make it easy to form and shape to your exact requirements.

Copper has outstanding electrical and heat conduction.

KDM copper sheet metal has a slow rate of corrosion. It is due to the molecular makeup of copper.

Copper material and copper sheet metal fabrication are surprisingly economical with KDM.

Copper Sheet Metal Fabrication Designs and Material

KDM produces all types of copper sheet metal such as copper brackets, copper contacts, copper chassis, copper shields, copper plates, copper bus bars, and so on. It is available in custom fabrication that fits your demands.

As a leading copper sheet metal fabrication provider, KDM has the ability to work with different copper grades and alloys such as C10100, C10300, C10500, C10800, C10920, C11300, C11400, C11500, C12000, C12200, C12500, C71640, C71500, C70620, C33000, and more.

These copper grades undergo material testing and inspections. It is certified to various certifications such as EN, GB, DIN, JIS, AISI, ASTM, etc.

KDM Copper Sheet Metal Fabrication

KDM can manufacture copper sheet metal into various parts or anything you want. We have a wide range of copper sheet metal fabrication capabilities that your project will use. It includes:

Copper sheet metal rolling – this process puts sheets of material between 2 constantly rotating rolls. This method reduces copper sheet thickness. It may also change the copper sheet grain structure.

Copper sheet metal bending – it uses a specific bending machine. This process results in a precise radius of the bend and an accurate bend angle.

Copper sheet metal stamping – method in which copper is cut and then created into exact shapes. This process results in copper’s thickness, and desired shape.

KDM Copper Sheet Metal Applications

Due to its versatility and durability, copper sheet metal is utilized for a variety of applications, especially for exterior roofing projects. It is malleable ideal for many roof shapes. This material can be hot or cold formed. It is ductile when heated.

KDM also manufactures copper sheet metal for automotive, and HVAC purposes. It has good workability and color best for welding fixtures. There high degree of conductivity and ductility features make it suitable for electrical sheet metal applications like power transmission components, spark plugs and terminals, grounding strips, anodes, electrodes, circuit breakers, etc.

Choose KDM to Custom Your Copper Sheet Metal

KDM has 10+ years of custom manufacturing experience which you can depend on. We are engaged in unique R&D, manufacturing, and sales of superior quality copper sheet metals. Our engineers utilize the most durable and rigid raw materials during fabrication.

Our range of copper sheet metal products is manufactured in compliance with ASTM, AISI, JIS, DIN, GB, EN, GB/T1527-2006, JISH3300-2006, GB/T5231-2001 standards, etc. You can ensure certified production at KDM.

Our company is composed of expert engineers and designers working closely to meet your needs. We can manufacture custom copper sheet metal using Panasonic welding machines, 3000W optical laser cutting machines, high speed, and precision stamping machines, etc.

For your next copper sheet metal fabrication requirements, always rely on KDM. We have 24/7 online assistance to ensure fast response and confirmation. KDM also offers secure custom packaging and delivery. Message us immediately!

KDM Copper Sheet Metal Fabrication

KDM offers secondary processes for copper sheet metal fabrication. Many common surfaces finishes are used on this material. These surface coatings deliver excellent benefits to copper to provide long-lasting life. Below are some surface finishes for copper.

- Mill finishing

- Polishing

- Anodizing

- Brushing

- Sandblasting

- Powder coating,

- Embossed

- Lacquering

- Electropolishing

- Mirror, etc.

KDM has rich experience working with clients worldwide. We bring their custom copper sheet metal ideas to reality and boom business. Through our advanced equipment and techniques, we can deliver premium copper sheeting for your unique applications. Below are the production capabilities we are experienced in:

- Cutting

- Stamping

- Welding

- Finishing

- Laser Cutting

- Forming

- Hardware Insertion

- Assembly

- Finishing

- Storage

OEM & ODM KDM Copper Sheet Metal Applications

KDM high-quality copper offers high electrical conductivity. Due to that feature, it is widely used for various electronics products. KDM is an expert manufacturer that can produce second-to-none copper sheet metal for electronics applications.

KDM has the right grade copper alloys to produce aerospace products such as bearings and bushings, wheel and brake components, landing gears and cargo doors, hydraulic pump components, pylons, wing, and tail actuator, etc.

KDM manufactures a wide range of copper sheet metal for construction. It is due to its good malleability, ductility, resistance to corrosion, and softer features, making it suitable for building industry such as components of pipes, cold water outlets, ventilation, and air conditioning, etc.

KDM manufacture copper for various communication devices such as copper battery clips. The thermal conductivity and high-electrical characteristics of copper make it one of the most useful materials in the production of all high-end communication devices.

Copper sheet metals are mainly used in the medical industry for external hospital devices. This product is utilized to help transmit signals to tiny implants and diagnostic equipment.

Why KDM is Trusted By Over 1000 Global Clients

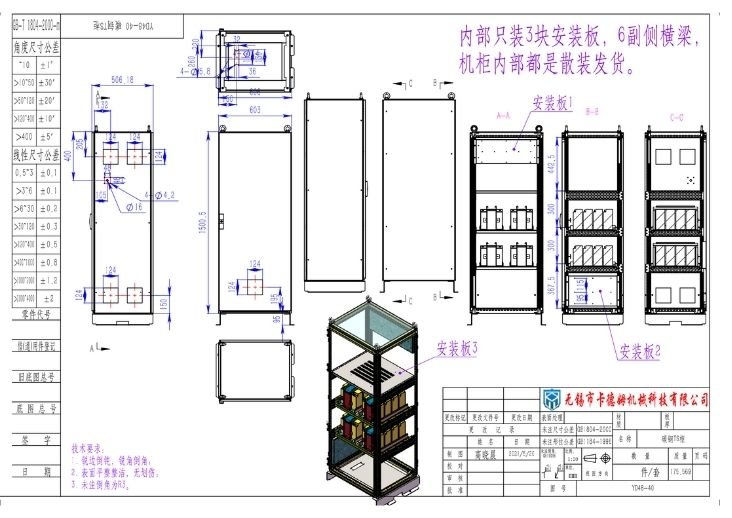

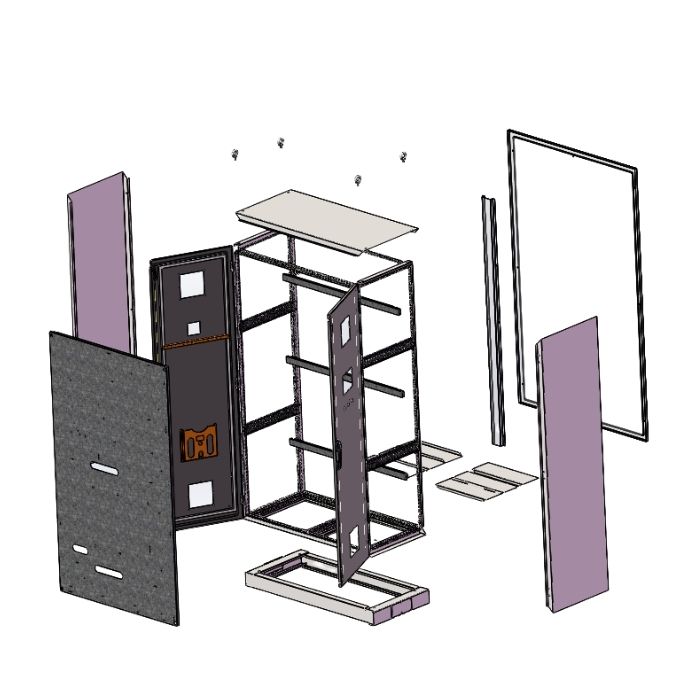

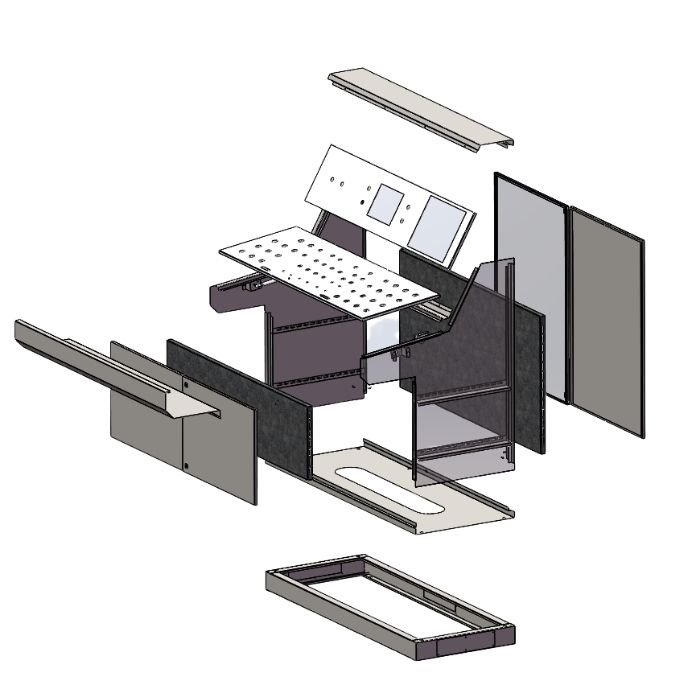

- Enclosure Manufacturing

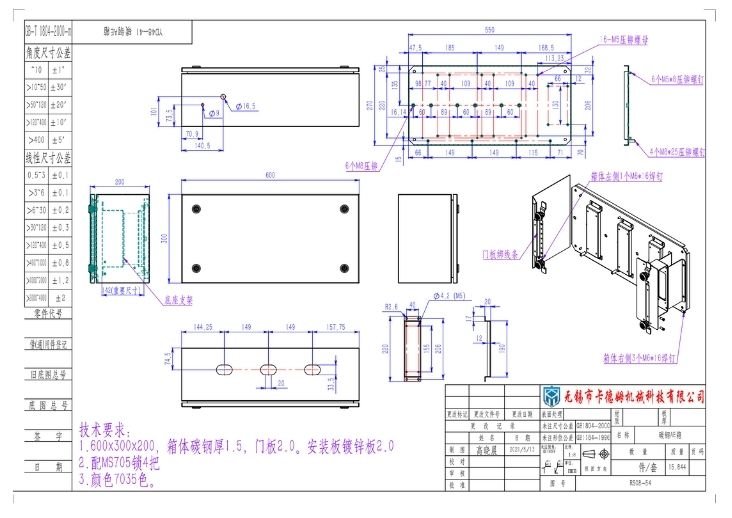

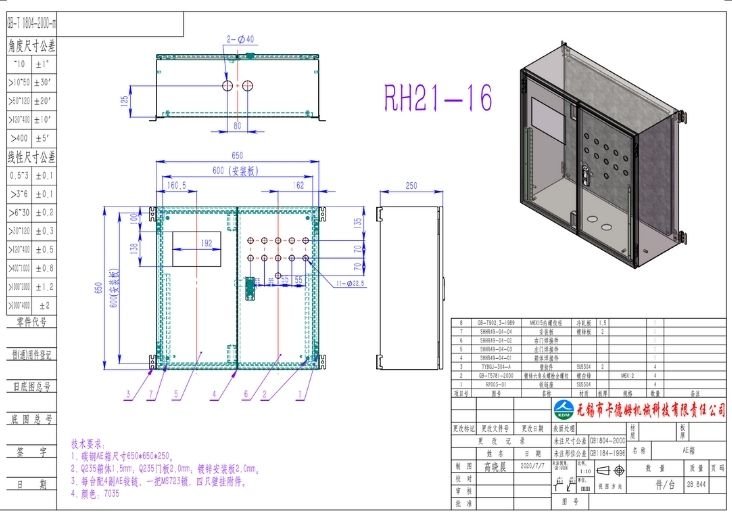

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure