If you are importing electrical enclosure insulation related products, then contact KDM directly and send us your requirements.

If you are learning any info about the enclosure insulation, then check below each question, click the one you are interested.

Keep reading.

- How Do You Calculate Heat Dissipation in Electrical Enclosures?

- What is the Best Material for Thermally Insulated Electrical Enclosure?

- Between Low-E Insulation and Enclosure Foam; Which One is Better?

- Are There Other Accessories Insulated Outdoor Enclosures Come With?

- When Should You Buy Insulated Enclosure Panels?

- What is NEMA 12 Electrical Enclosure?

- Are There Significant Differences Between NEMA Type 4X and NEMA Type 4?

- What is R-value?

- How Do You Choose Insulated Equipment Enclosures?

- Are There Different Classes of Electrical Enclosure Insulation?

- Which Variables Affect Thermal Management in Electrical Enclosures?

- Is Polycarbonate a Perfect Thermal Barrier Enclosure?

- Can You get NEMA Enclosure With Heater and Fan?

- What Benefits Do Thermally Insulated Electrical Enclosures Offer?

- What are IP Ratings for Outdoor Electrical Enclosure Insulation?

- How Do Thermal Management Systems for Electrical Enclosure Work?

- Does Ventilated Electrical Enclosure Improve Heat Dissipation Efficiency?

- Are There Design Rules for Electrical Enclosure Insulation?

- Which Quality Certifications Should You look for in Electrical Enclosure Insulations?

- What Electrical Enclosure Design Options does KDM Steel Offer?

- Does KDM Steel Has MOQ for Custom Electrical Enclosure?

How Do You Calculate Heat Dissipation in Electrical Enclosures?

You need first of all to determine the input power of the heat generated within the electrical enclosure in watts.

Secondly, you need to calculate outside heat transfer in the following ways;

- Determining the area exposed to the air in square feet and at the same time ignoring the top of the cabinet.

- Determining the temperature differential between the maximum surrounding temperature as well as the desired internal temperature.

Then, you’ll use a temperature conversion table to determine the Btu/hr./ft.2. for that particular differential.

Upon multiplying the cabinet surface area times Btu/hr./ft.2. gives you the external heat transfer in Btu/hr.

Then finally, you can now add the internal and external heat loads for total heat load.

Heat circulation in electrical enclosure

What is the Best Material for Thermally Insulated Electrical Enclosure?

Ideally, polyisocyanurate foam and polyurethane are the best materials to use in a thermally insulated electrical enclosure.

Polyisocyanurate foam, also known as polysio foam is essentially a cellular, thermoset that is formed as a result of a combination of isocyanurate and polyol, in the presence of a catalyst.

It is considered among the best material given that the combination of these different liquid chemicals and catalyst help in creating closed cells and flame retardants in its structure.

Polysio foam is generally, an inert, non-nutritive, and highly stable rigid foam which has the highest strength to weight ratio and superior thermal insulating value.

Polyurethane is the other one of the best material for a thermally insulated electrical enclosure.

It is rigid, and a high-performance material which displays excellent thermal insulation properties.

It is also a highly cross-linked thermoset plastic of low density.

So it happens that the low thermal conductivity of the blowing agent that’s contained in the cell is what gives this material excellent insulating properties.

Between Low-E Insulation and Enclosure Foam; Which One is Better?

Low E-insulation offers excellent thermal performance and at the same time conserving the valuable interior space for your enclosure.

It happens that it’s manufactured using polyethylene foam core with a reinforced double sided aluminum scrims facings.

The fact that it is lightweight, easy to install is vital, adding to the fact that you can as well use it in a wide range of applications to improve energy efficiency.

Remember you can also pair with several accessories including heaters, thermostats, air conditioners and sun shields among others.

On the other hand, an enclosure foam tends to adhere to the interior of the pans, thus providing increased structural strength and air-tight seal.

Floor standing electrical enclosure

However, in comparing the two, low-E insulation tends to be relatively better than the enclosure foam since it has several properties and portrays better results.

Are There Other Accessories Insulated Outdoor Enclosures Come With?

Yes. Insulated outdoor activities either come with quite a number of insulated outdoor enclosures or better still, you can pair them.

Some of these accessories include;

Air conditioners – quite a number of insulated outdoor enclosure come with air conditioning systems, especially those which are exposed to hot environments.

Sun shields – most of them are custom-made to fit a variety of insulated enclosure designs.

Thermostats – it is among the most common since the enclosure thermostat makes it possible for the heater or fan to turn on and off automatically.

Heaters- they help in maintaining a constant temperature within the enclosure, particularly if it is one which remains exposed to the elements.

When Should You Buy Insulated Enclosure Panels?

It is dependent on quite a number of factors.

For instance, you may buy one after considering the type of application that you want for your project.

When you want to construct telecommunications shelters, battery cabinets, gas utility enclosures, meter station buildings, backflow preventer shelters.

You may also want to buy one after considering the general environment of the area where you want to install the enclosures.

You may also consider buying this type of equipment when fixing odorization cabinets.

The most important thing after all is making sure that you buy it when you feel the need for using it accordingly.

What is NEMA 12 Electrical Enclosure?

It refers to an industrial enclosure which is constructed to provide relatively more protection than the other NEMA standards enclosures.

Such enclosures are intended specifically for industrial manufacturing as well as a variety of machining applications.

NEMA 12 electrical enclosure protects against dust, dripping non-corrosive liquids, dirt, lubricants, and oils, among others.

NEMA 12 Electrical enclosure

Some of the key characteristics of this type of enclosure include; resistant to damage, especially from external condensation, and doors which feature oil-resistant gasket.

General, it is a type of enclosure which protects manufacturing control and automation instruments for packaging, as well as material handling applications.

Additionally, the construction of NEMA 12 enclosures incorporates added quality steps by veteran artisans and obtainable at an affordable rate.

It comes with cutouts, insulation, pre-punched holes, lift-off hinges as well as latches among others.

Are There Significant Differences Between NEMA Type 4X and NEMA Type 4?

Yes. One of the major differences between these two NEMA ratings is that NEMA 4X enclosures provide better or additional corrosion resistance.

And what makes this difference quite significant is the fact that NEMA 4X enclosures must always pass a rigorous series of corrosion tests.

NEMA rated electrical enclosure

One of these tests includes 1200 hours of exposure to moist air, which contains sulfur dioxide and carbon monoxide.

Moreover, it should also pass this test by exposure in a salt spray test for at least 800 hours.

Another key difference between these two NEMA ratings is the NEMA type 4 is comparatively non-explosion proof.

So it means that compared it to NEMA 4X, it is not necessarily suitable to use in more hazardous applications where it easily explodes.

Then the other significant difference is the NEMA 4 enclosures offer better water-proof protection than NEMA 4X.

In other words, you cannot ideally submerge NEMA 4X enclosure in water.

What is R-value?

It refers to a measure of resistance to heat flow through a provided flow of material.

You can also describe it as a measure of how ideal a two-dimensional barrier like a layer of insulation wall ceiling or a complete wall resists the conductive flow of heat.

So it is primarily the difference in temperature per unit of heat flux which is needed to sustain one unit of heat flux between the colder and warmer surface of a barrier under steady-state conditions.

It is essential in the sense that it helps in determining the effectiveness of insulation material.

In other words, this term means the thicker the insulation, the more efficiently you can enhance the safety and comfort of your home.

Therefore many construction industries prefer using the R-values.

It happens that an apparent R-value tends to quantify the physical quantity known as thermal insurance.

How Do You Choose Insulated Equipment Enclosures?

Quite apparently, there are several elements that you need to understand and look into to guide in you choosing insulated equipment enclosures.

The kind of environment where you’ll place your enclosure and level of protection that you require are some of the key ways of choosing this equipment.

The protection level for an insulated equipment enclosure is defined by its particular NEMA rating.

You also need to factor in the temperature.

You see, this type of equipment must be able to stand up to high heat, especially in areas where heat-generating machinery is at work.

The particular application for the task would also make it possible for you to choose this type of insulated equipment.

The point here is that product applications often tend to relate to the requirements of the physical enclosure.

Another way of choosing this item is by determining the thermal management requirements and performance standards.

And finally, you also need to look into the material when choosing an insulated equipment enclosure.

You see, whether you go for metallic or non-metallic will depend on the application and environment too.

Are There Different Classes of Electrical Enclosure Insulation?

Yes.

Electrical enclosure insulation are grouped into the following classes;

- Class A – consists of materials such as paper, cotton, and silk when coated or immersed in a dielectric component like oil.

- Class B- consists of a combination of materials like asbestos, glass fiber, mica that have suitable bonding or coating substances. Other organic materials may as well be included in this class.

- Class C – comprises of the material or combination of material like quartz, glass, porcelain, and mica with or without an inorganic binder.

- Class E – comprises of materials or combination of the same which through the tests can be shown to be capable of operating at class E temperature.

- Class F – consists of materials or a combination of the same as mica, asbestos, and glass fiber with suitable bonding or coating substances.

- Class H – made of materials such as silicone elastomer or a combination of different materials, including glass fiber, asbestos, and mica with suitable bonding substances.

Which Variables Affect Thermal Management in Electrical Enclosures?

- Conduction – it refers to the flow of the heat through the solid electrical enclosure material.

- Temperature – heating, and cooling become necessary in electrical enclosure thermal management as a way of maintaining optimal temperature, ensuring components do not overheat or condense.

- Convection – it is the movement of heat through a moving fluid substance or from moving gaseous material to the surface of the solid.

- Surface area – the total area within the enclosure, plays an integral role in determining the efficiency of thermal management.

- Radiation- it refers to the transfer of thermal energy from and from electromagnetic energy through conversion.

- Enclosure material – electrical enclosures are made of either metallic or non-metallic materials. The choice of either also has a significant effect on the overall thermal management.

Is Polycarbonate a Perfect Thermal Barrier Enclosure?

Yes.

Apparently, polycarbonate material has some of the excellent qualities that make it one of the best components for thermal barrier enclosure.

Polycarbonate electrical enclosure

It offers high heat deflection temperature and tends to absorb relatively little moisture.

Other than that, it also provides high impact strength as well as high modulus of elasticity.

Polycarbonate has a low coefficient of thermal expansion as well as excellent strength retention at elevated temperatures.

So as you can see, these properties, in addition to low frequency and high voltage insulating characteristics, enables it to be prime material for thermal barrier enclosure.

Can You get NEMA Enclosure With Heater and Fan?

Definitely yes.

In fact, most of the NEMA enclosures that are currently hitting the market come installed with a heater and a fan.

Both of these accessories play a fundamental role in determining the efficiency of the enclosure as far as temperature regulation of this equipment is concerned.

Electrical enclosure with a fan

NEMA enclosures with heater are ideal or rather suitable for cold environments and feature a thermostat controlled heating system.

In most instances, you’ll notice that the heater is fixed below the mounting plate and wired internally.

The essence, in this case, is to ensure that it does not interfere with the use of installed equipment or in some cases requires the use of AC outlets.

On the other hand, the NEMA enclosures with a fan are more suitable for relatively hot environments.

Other than just a thermostat control cooling fan, most of them also have a cooling feature dual vents.

The NEMA enclosure fan is characteristically quiet, provides high airflow, and helps in maintaining low internal temperatures.

The fan in this equipment is wired internally to avert the need of using AC outlets hence leaving them for internal equipment use.

What Benefits Do Thermally Insulated Electrical Enclosures Offer?

Well, a properly thermally insulated electrical enclosure provides quite a number of long-term benefits including the following;

Thermally insulated electrical enclosure

- It helps in enhancing the safety of the equipment because if the dissipated heat is not removed, then it can cause insulation damage, which ultimately affects the whole system.

- Insulation helps in improving personnel safety, given that most of these enclosures are always fixed in an area where employees frequent. Therefore, it can be hazardous to their lives and wellbeing.

- It also helps in reducing the risks of fire or explosion, which is often common with hot electrical equipment. Insulation damage often causes short-circuiting and fire as a result.

- Thermal insulation also helps in reducing the cost of energy since the equipment shall have moderate power utilization.

- It also comes in handy as far as the prevention of moisture condensation is concerned.

- It reduces the size as well as the capacity of new mechanical equipment hence enhancing efficiency and performance.

- It helps in reducing noise levels, which is essential, especially when fixed in areas where people work. Additionally, insulation also improves the appearance of the equipment.

What are IP Ratings for Outdoor Electrical Enclosure Insulation?

The IP ratings for this equipment are quite a number and include the following;

IP rated electrical enclosure

- IP54 – protection from limited dust ingress and water spray from any direction.

- IP55 – protection from limited dust ingress and low-pressure jest from any direction

- IP56 – protection from limited dust ingress and high-pressure water jets from any direction.

- IP57 – protection from limited dust ingress and immersion between 15cm and 1 meter deep.

- IP 58 – protection from limited dust and long term immersion up to a specific pressure.

- IP 60 – protection from total dust protection but not from the liquid.

- IP 61 – protection from total dust ingress and condensation.

- IP 62 – protection from total dust ingress and water spray in less than 15 degrees from the vertical angle.

- IP 63 – protection from total dust ingress and water spray less than 60 degrees from a vertical angle.

- IP 64 – protection from total dust ingress and water spray from any direction.

- IP 65 – protection from total dust ingress and high-pressure water jets from any direction.

- IP 66 – protection from total dust ingress and high-pressure water jets from any direction.

- IP 67 – protection from total dust ingress and immersion between 15cm and 1 meter deep.

- IP 68 – protection from total dust ingress and long term immersion up to specific pressure.

- IP 69K – protection from total dust ingress steam-jet cleaning.

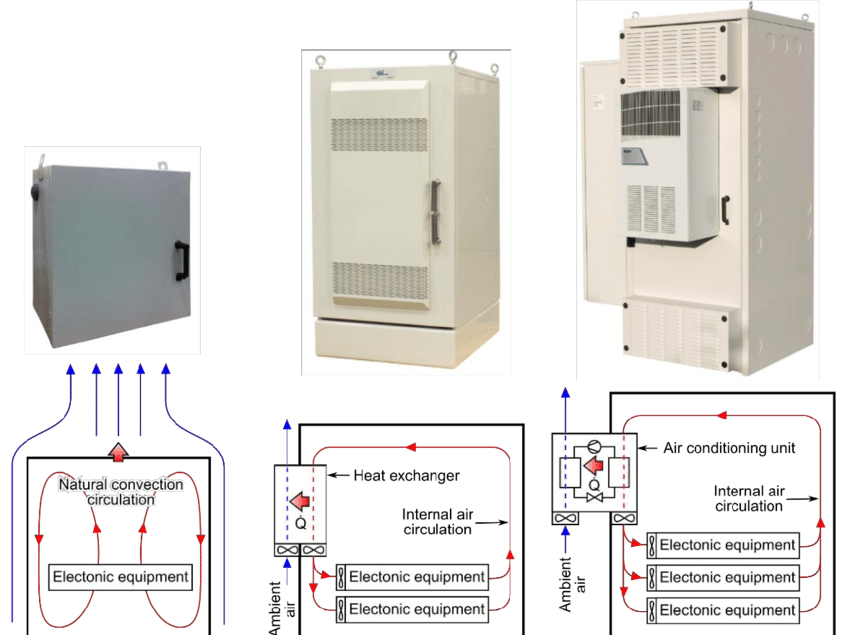

How Do Thermal Management Systems for Electrical Enclosure Work?

Heat is transferred from one object in the enclosure to another one to a high and low temperature respectively with significant heat capacity.

Thermal management in electrical enclosures – Photo courtesy: Processing Magazine

So it happens that the transfer of thermal energy which is quite rapid brings the first object into thermal equilibrium with the second object.

In that event, the temperature of the first object reduces hence accomplishing the role of the heat sink as a cooling device.

Ordinarily, the most common design of a cooling device is a metal that comprises of many fins.

Therefore, the high thermal conductivity of this metal combined with its large surface area leads to the rapid transfer of the thermal energy to the surrounding cooler air.

It thus cools the enclosure and any other object that it’s in direct thermal contact with.

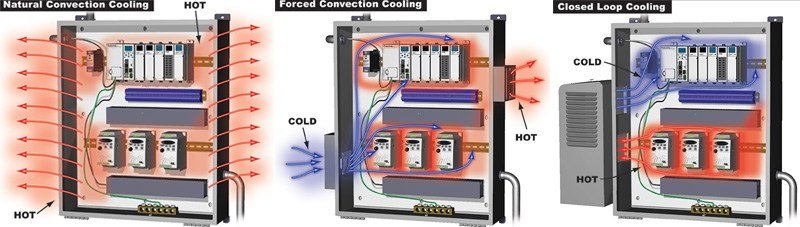

Does Ventilated Electrical Enclosure Improve Heat Dissipation Efficiency?

Yes.

Proper ventilation within the electrical cabinet makes it possible for heat to circulate freely hence enhancing efficiency.

Vented electrical enclosure

Ventilation helps in controlling the level of heat that the enclosure can retain hence improving its heat dissipation efficiency.

Are There Design Rules for Electrical Enclosure Insulation?

Yes.

And most of the design rules, in this case, revolve around ensuring that the enclosure is the insulating material remains still even in extreme situations.

- One of the design rules is making sure that the insulating material has excellent thermal stability.

- Also, ensure that it has good resistance to both abnormal heat and normal heat as well.

- The material must also be resistant to ultraviolet radiation, especially for enclosures made for outdoor applications.

- You have to come up with design verification plans. These need to include tests and checks which you require to carry out on the enclosure.

- You also need to clearly define the niche markets for selling the particular insulated enclosure product before designing.

- Feed-in previous experiences into the design, more importantly, feedback from past test failure or certification issue.

- You have to do a risk analysis on the safety and efficiency of the insulation material before fixing it on the enclosure.

- Involving key potential suppliers at an early stage is commendable. It helps in tapping the contribution of their wealth experience, which is vital to the success of the design.

Which Quality Certifications Should You look for in Electrical Enclosure Insulations?

- CE- refers to a certification mark that specifies conformity with health and environmental protection standards for products sold in the European region.

- ENEC – refers to a high-quality European certification mark designed for electrical products which comply with stipulated European safety standards.

- UL – refers to certification standards, which define a product’s conformity to all its extensive research and scientific expertise.

- ETL – refers to an equipment safety certification program that includes different variations designed to fit within safety and sanitation standards of the product.

- VDE – refers to a standardization entity responsible for certification of safety and regulations for electrical and electronic information technologies.

What Electrical Enclosure Design Options does KDM Steel Offer?

At KDM steel, some of the major enclosure design options include;

- Single door steel enclosure

- Triple door steel enclosure

- Double door steel enclosure

- free standing

- modular electrical enclosure

- floor mount steel enclosure

- Wall mount electrical enclosure

- Junction boxes

- Marine electrical enclosures

As you can see, these options are quite a several, which is essential especially when you’re looking for a specific one which suits your application needs.

So all these enclosure design options from KDM steel allow you to settle for the most suitable one.

Does KDM Steel Have MOQ for Custom Electrical Enclosure?

Yes.

It has a very low MOQ of 1 piece regardless of the type of custom electrical enclosure.

Now, this is interesting because you realize that you’re not limited to a particular quantity that you can purchase from KDM steel, whether normal or customized.