Your leading stainless steel electrical enclosure manufacturer, custom any industrial electrical enclosures for your projects.

As one of the electrical enclosure manufacturers,

KDM specialized in custom-made AISI 304 and AISI 316 corrosion-resistant stainless steel electrical enclosures.

Professional Stainless Steel Electrical Enclosure Manufacturer

Stainless Steel electrical enclosures are KDM’s star products. KDM has been focusing on the manufacturing of stainless steel electrical enclosures for almost two decades.

Therefore, a huge amount of experience has been accumulated and the manufacturing processes have also been significantly improved over the years. KDM’s stainless steel electrical enclosures come with three material options, 201 stainless steel, 304 stainless steel as well as 316 stainless steel.

KDM Stainless Steel Electrical Enclosure Series

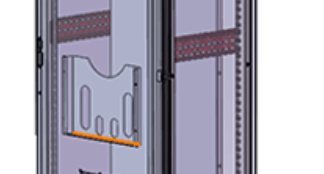

The indoor use stainless steel wall mounts electrical enclosure with doc pocket is a standard item in KDM. For wall mounting, we provide galvanized steel mounting bracket. The enclosure door and enclosure are equipped with earth studying. For IP and NEMA ratings, we can make them based on your standards. Ask us now.

This 316 stainless steel enclosure can be made with a polycarbonate sheet or fire-proof glass window, so you see your data easily. We can custom the window size based on your electrical parts in the enclosure. We can also custom the holes and fixtures based on your different electrical components.

The 316 stainless steel junction box is a perfect choice for the protection of electrical parts in the electrical facility setting. You can select such junction boxes in our standard size boxes. Of course, you can also custom your own sizes based on your electrical parts. We can provide the din rail, mounting plate, mounting brackets, and other accessories per your request also.

Quality SS Enclosure Manufacturing

KDM is an expert for stainless steel enclosure manufacturing. Our stocking material includes SS201, SS304, and SS316L. With ISO9001 standard, we have quality control for each step. With 10 years experience above welding and polishing workers, the polishing areas of KDM enclosures have the consistent hair line finish with the rest of the enclosure.

Effective Anti-Corrosion

Enclosures made of 201 stainless steel, 304 stainless steel as well as 316 stainless steel, these three materials are known for their toughness and corrosion resistance,

while 304 and 316 are the most popular choices for KDM’s electrical enclosures, especially for outdoor applications and 201 stainless steel acts as a lower-cost alternative with relatively lower corrosion resistance while having the same appearance as the other two.

However, both KDM’s 304 and 316 stainless steel electrical enclosures provide much more than better corrosion resistance.

The 304 stainless steel electrical enclosures enjoy superior restriction of carbide precipitation during welding,

This ensures almost lifetime durability while the electrical enclosures made of 316 stainless steel have higher corrosion resistance than both 201 and 304 and higher creep strength.

Therefore, based on your application and budget, you will be able to find stainless steel electrical enclosures with optimal materials.

Quality IP and NEMA Box Fabrication

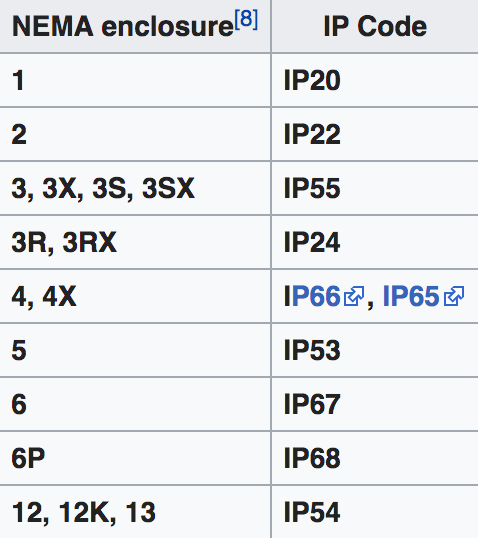

We offer any NEMA type of enclosures, as well as IP-rated enclosures up to IP66.

NEMA types go up to 13, with many numbers having lettered subtypes.

These types don’t ascend in strength necessarily, but each outlines specific qualities they have, such as protecting against corrosive agents and coolant seepage.

If you want to learn more, we also provide NEMA enclosures, as well as another very informative guide.

As for the IP rating, it consists of 2 digits that correspond to protection against solid and liquid ingress, respectively.

As such, IP66 means that the enclosure is fully dustproof and can withstand powerful water jets, as well as being temporarily submerged.

If you would like to learn more, we have an IP66 certification that you can take a look at.

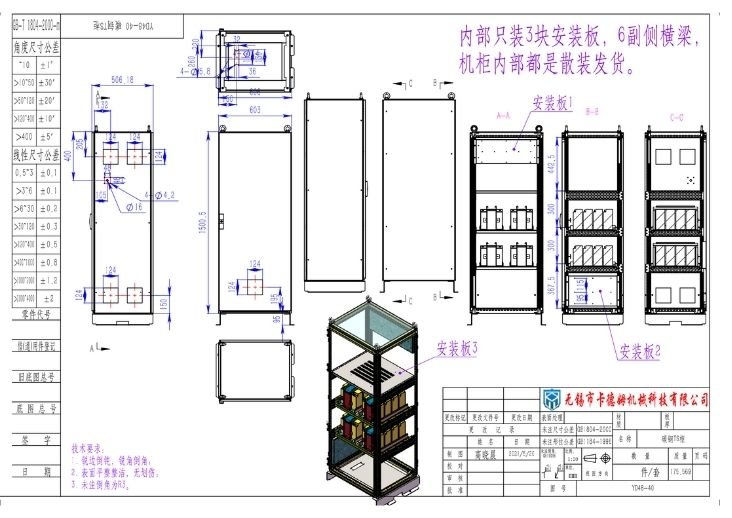

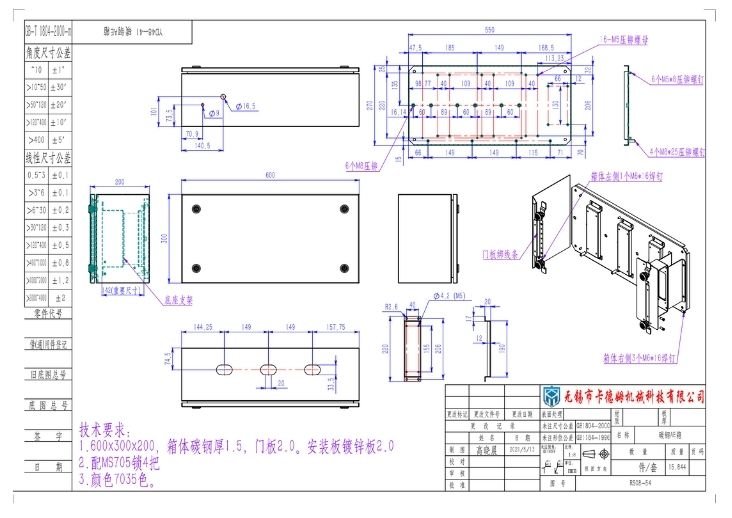

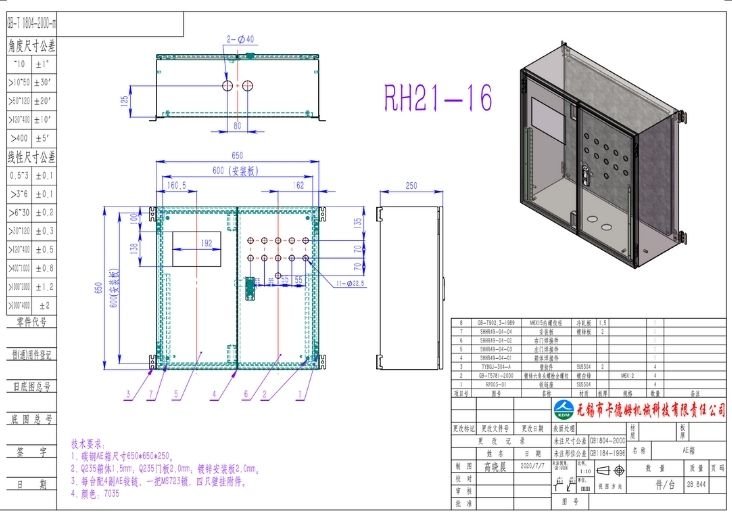

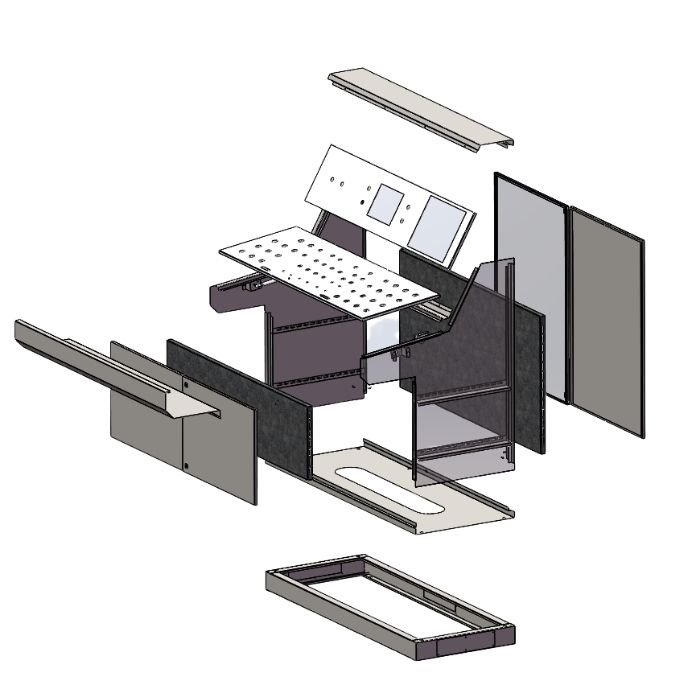

How KDM Customise Your Stainless Steel Electrical Cabinet

KDM can custom the SS enclosure based on your requirements. You can provide us your drawings for custom making. You can also just tell us your required details. Our engineers will make the drawing per your spe. In addition, we can also provide all kinds of accessories to meet your electrical parts setting up.

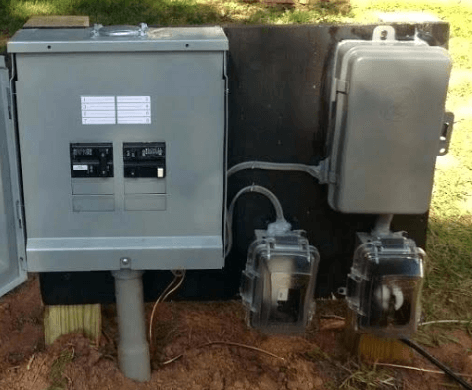

Wide Applications for Your Industry

KDM stainless steel electrical enclosures can be used for both indoor and outdoor applications. They are now the indispensable part for the electrical equipment and electric system protection, such as home electric control enclosures, factory machines control panels, the outdoor telecommunication enclosures, all kinds of battery enclosures, solar system enclosures and so on.

Accessories

KDM can offer you all kinds of enclosure accessories to facilitate your assembly work. The accessories include all kinds of hardware part, such as the din rail, rain canopy kit, the wall mounting kit and so on. We also provide many standard panel electrical parts such as the ventilation fan, the light, etc.

More Manufacturing Process for KDM Stainless Steel Electrical Enclosure

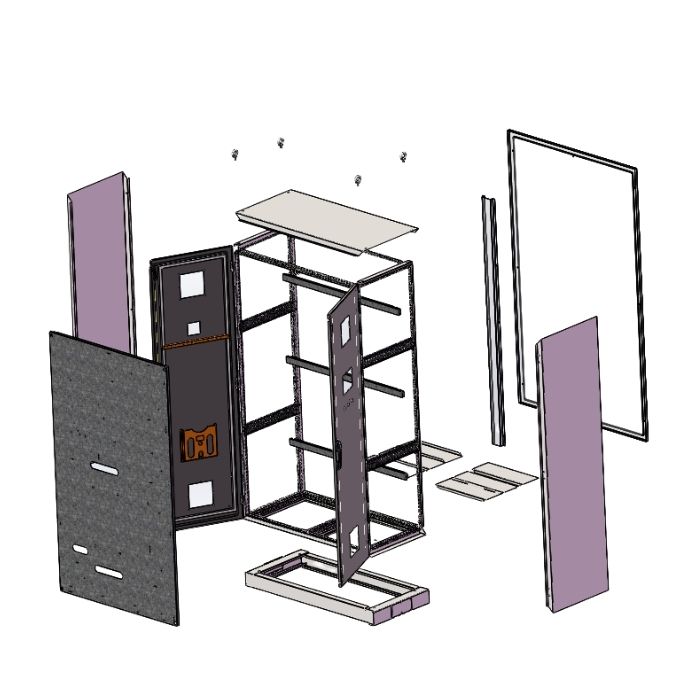

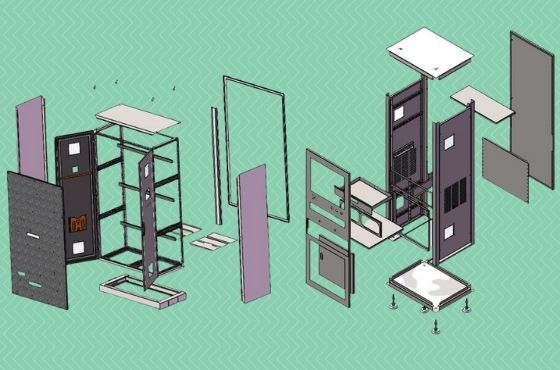

KDM offers stainless steel electrical enclosures in different layouts and mounting types, including free-standing stainless steel electrical enclosures, floor mount stainless steel electrical enclosures, wall mount stainless steel electrical enclosures, as well as junction box stainless steel electrical enclosures and stainless steel modular enclosures.

KDM also provides electrical enclosures with a variety of accessories and features, such as vents, windows, back panels, lifting eyes, rain caps, etc.

Last but not least, all KDM electrical enclosures have satisfied certain NEMA or IP standards and will provide outstanding protection for your electrical systems.

- Precision: +/- 1mm tolerance for overall cabinet size

- Standard Configuration: Gland plate, radiating fan, fluorescent lamp, lamp switch, ground connections, PU foaming seals.

- Warranty: 1-year warranty for KDM SS electrical enclosure, you will get free accessories within our warranty

- NEMA Rating: KDM can manufacture all types of NEMA Rating Enclosure for your project

Why KDM is Trusted By Over 1000 Global Clients

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

- Electrical Enclosure

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure

Stainless Steel Double Door Free Standing Electrical Enclosure with File Pocket and Air Filter

The stainless steel double door electrical enclosure can be with a doc pocket and air filter. We can make it free-standing, or floor mounted. For different applications, we can make the side panel welded as an overall set, or assembled with the frame which is more flexible in setting up. For the doc pocket and air filter, we can provide different designs options for your checking.

Wall Mount Stainless Steel Electrical Enclosure with Window

Wall mount stainless steel electrical enclosure with window is a good choice for your equipment. You can see the figures directly from the visible window. The window material can be acrylic, pc, or fire-resistant glass. For wall mounting, we can provide galvanized steel or stainless steel bracket for easy fitting. For cable entry, we can offer you the gland plate or rubber hole sealing. For details, email us now.

Double Door Stainless Steel Enclosure

The double door stainless steel enclosure is very easy for the electrical facility setting up. With the middle bar, we can make this enclosure IP65 and IP66 standard also. You can use the combination lock or padlock for such enclosures. The mounting plate can be made out of galvanized steel, or powder coating sheet.

304 Stainless Steel Electrical Enclosure

The 304 stainless steel electrical enclosure can be used both indoor and outdoor. You can get all enclosures accessories, such as base plate, din rail, fixtures, bottom base, and so on preassembled on our side. You can also have the masking panel, document pocket, visible acrylic window, or fire-proof glass window options from us. All our work will make your electrical enclosure meet all your demands.

Double Door Free Standing Stainless Steel Electrical Enclosure

Double door free standing stainless steel electrical enclosure is a great choice to protect large electrical equipments. With double doors, you can easily get your electrical parts in the enclosure. For high power electrical parts, you can consider ventilation fans design on both side panels. You can have shelves in the enclosure if you want to organize the parts.

Floor Mount Stainless Steel Electrical Enclosure with Window

Floor mount stainless steel electrical enclosure with window is very convenient for you if you have to read data often. As it is stainless steel material, you can set it in the house or outdoor. The outside door can be locked securely. For the masking panel or inner door, you can decide whether you need a lock or clip only. Mounting feet is an optional accessory. You can order the complete mounting kits from us as well including the bolts.

Floor Stand Stainless Steel Electrical Cabinet

You will need square tube bracket mounting base if you want to fix the electrical cabinet some distance from the ground. For competitive prices, you can use powder coating or galvanized steel base if the environment is not so tough. Tell KDM about the weight of your electrical parts installed in the cabinet, so we will decide the steel thickness required for the base bracket.

Operator Interface Stainless Steel Electrical Enclosure

Operator interface stainless steel electrical enclosure normally comes with a sloped hood. It is also with outside door, and inner masking panel. You can decide the window size based on the electrical parts. We can provide the custom size for the pole base based on the weight capacity.

Outdoor Free Standing Lockable Enclosure

Outdoor free standing lockable enclosure is a rust proof enclosure with sloped roof. We can provide different base designs to meet your demands. If you need some standard accessories such as fans, led light, power rail and so on, we can set them directly in the enclosure. Any question, inquiry us now.

Outdoor Free Standing Stainless Steel Electrical Enclosure

The outdoor free standing stainless steel electrical enclosure can be made out of stainless steel 304, or stainless steel 316L. To ensure the ventilation and IP rating, we can add both ventilation cutout, filter and filter cover in the enclosure. The rain hood is a must for outdoor enclosures. For inner hardware setting, you can choose based on different electrical equipment. Contact us now for more details.

Outdoor Modular Stainless Steel Electrical Enclosure

The outdoor modular stainless steel electrical enclosure helps maintain the proper working of the electrical facility. With modular items, it is easy for you to expand the enclosure if you have more electrical parts to get in the enclosure. You can combine two enclosures into one complete set. Stainless steel material keeps a longer life for the enclosure. For more details, please email us.

Outdoor SS Electrical Enclosure with Window

Normally we make outdoor ss electrical enclosure with window. In this way, you can easily check the data often without opening the door. For easy operation and setting, we can add eye hooks at the top for you. For easy ventilation, we can add the cutout at the side panel. If you have requirement on the IP rating, we can add the filter and cover out side the cutout. Contact us now.

Outdoor Wall Mount Stainless Steel Electrical Enclosure

The outdoor wall mount stainless steel electrical enclosure can be mounted on the wall by the additional mounting bracket, or the studs from back panel to the wall. Based on the temperature and ventilation status, you can decide whether you need insulation for the enclosure. With the insulation, the enclosure maintains the proper working temperature. Contact us now.

Single Door NEMA 4X Stainless Steel Electrical Enclosure

The single door Nema 4x stainless steel electrical enclosure is equivalent to IP66 enclosure based on the dust and water protection. It is very suitable to be used both indoor and outdoor. The enclosure is also corrosion resistant, and can be used in the applications such as marine equipment. For more details, please feel free to contact us now.

Stainless Steel Electrical Enclosure IP 65

Stainless steel electrical enclosure with IP65 rating is the most popular item in KDM business. This enclosure can be used both indoor and outdoor with good protection against the dust and water intrusion. KDM pay special attention to the welding details. We’ve got customer comments for good surface treatment from many customers. Please contact us now if you would like to have a sample for checking.

Floor Stand Stainless Steel Outdoor Modular Enclosure

The floor stand stainless steel outdoor modular enclosure is widely used for outdoor electrical protection. The top hood is customized based on the enclosure size and design. The plinth part can be made out of stainless steel or metal with powder coating. For other accessories details, we can design and make them based on your requirements. For details, please contact us now.

Hinged Stainless Steel Electrical Enclosure

KDM can offer all kinds of hinged stainless steel electrical enclosures. We can custom the hinge details according to different standards. The door can be open in 90 degrees and 130 degrees. You can select the standard hinges, and also piano hinges for different applications. If you have any questions, contact us now.

Multi door nema 12 stainless steel enclosure

The multi door Nema 12 stainless steel enclosure is normally used in indoor. For this design, you can put all your electrical equipment in the enclosure easily. To fit different facilities, we can custom the fixtures such as shelvings, mounting plate and so on to fix them suitably. We can design filters and ventilation details based on your whole structure as well.

NEMA 4X Enclosure Stainless Steel with Window

Nema 4x enclosure stainless steel with window is a fantastic enclosure to be used outdoor. It is resistant to the outside force impact, dust and water intrusion. The window is glued to door panel. This makes the dust and water hard to get into the enclosure. For the double door items, we will add a middle bar between two doors for better IP rating. For more details, contact us now.

Outdoor Stainless Steel Electrical Cabinet

For outdoor stainless steel electrical cabinet, the top hood is an indispensable part. The rain will go down the rough without splashing into the enclosure surface. For higher power facility, we will give ventilation design on the enclosure. We can custom the bottom plinth based on different enclosure designs. For any suggestions required, contact us now.

Triple Door Stainless Steel Outdoor Enclosure

The triple door stainless steel outdoor enclosure is a good choice for electrical parts protection. The eye bolts at the top helps with the enclosure lifting. The middle door can be fixed or openable based on different designs. The base part can be set with cable entry at the bottom or at the side panel. To get a customized design, you can contact us for details.

Double Door Free Standing Stainless Steel Electrical Enclosure

The double door free standing stainless steel electrical enclosure can be used both indoor and outdoor. We can do the cutout according to your specific demand. The cable entry, mounting plate, doc pocket, fixing brackets and so on can be also customized based on your need. For details, contact us now.

Double Door Stainless Steel Free Standing Enclosure with Door Handle and Hinge

KDM can custom your enclosure, such as the double door stainless steel free standing enclosure with door handle and hinge. For the door handles and locks, we have dozens of designs for your selection. All are from branded hardware partners. You can select the favorite one. For ventilation and air circulation, we can design it based on our experience. Contact us now.

Free standing Stainless Steel Corrosion-Resistant Electrical Enclosures

Free standing stainless steel corrosion resistant electrical enclosure has a good protection against all kinds of damages, such as the dust and water intruding, corrosion and so on. With different facility to be set in the enclosure, KDM will give you the advice on the gauge of stainless steel used for each design. For more details, email us now.

Free Standing Stainless Steel Electrical Cabinet Enclosures

Free standing stainless steel electrical cabinet enclosure is a good selection for lots of customers. Based on your spe, we can design the enclosure in one door, double door, front door or rear door. All together makes it easy for you to fit in the your equipment. Side panel can be directly welded or with frame structure which is easier to be assembled. For details, contact us now.

Free Standing Stainless Steel Electrical Cable Enclosure with Doc Pocket

Free standing stainless steel electrical cable enclosure with doc pocket has cable entry at the bottom and also at the side. The gland plate to cover the hole is well sealed with rubber. This prevents dust and water from getting into the enclosure. We provide hundreds of locks and latches for your selection. Ask us now.

Free Standing Stainless Steel Electrical Control Enclosure with Doc Pocket

The free standing stainless steel electrical control with doc pocket can be used both indoor and out door. The enclosure is precisely bended and well polished in the corner. In this way, the drawing effect on the surface of enclosure is nice and consistent. Based on the equipment size, you can decide to choose single door enclosure, or double door enclosure. For details, you can contact KDM now.

Free Standing Stainless Steel Electrical Enclosure with Ventilation Control

The free standing stainless steel electrical enclosure with ventilation control is designed for the high power equipment. The ventilation fan can be set on the top and the heat will be vented out. The bottom part can be designed with the louver so the cool air outside can get it. For more details, contact us now.

Free Standing Stainless Steel Electrical Enclosure with Hinges

Free standing stainless steel electrical enclosure with hinges are made out of stainless steel for both the enclosure and hinges. The door opening angles can be of different choices such as 90 degrees and 130 degrees. You can share with us the function and durability for your enclosure, and we can custom the enclosure for you.

Free Standing Stainless Steel Electrical Metal Enclosures

Free standing stainless steel electrical metal enclosure is made out of stainless steel for the door and enclosure. The mounting plate is made out of steel with powder coating. The plinth can be made out of stainless or powder coated metal as well. If you have specific details, email us for further discussions.

Free Standing Stainless Steel Ventilated Electrical Enclosures

Free standing stainless steel ventilated electrical enclosures is a great choice for both indoor and outdoor applications. KDM can do all kinds of custom features per your request, such as the eye bolts at the top, ventilation louver as the side panel, entry holes at the top and at the front and so on. All designs and drawings revisions are free of charge. Contact us now.

Outdoor Free Standing Stainless Steel Modular Electrical Enclosure with File Pocket

The outdoor free standing stainless steel modular electrical enclosure with file pocket is also a common enclosure with customized features. Based on your standards, we can make them to meet all IP ratings, Nema ratings, and CE compliance. With ISO certified, KDM can offer you all kinds of enclosures with custom requirements. If you want to do the design for your enclosure, contact us now.

Outdoor Weatherproof NEMA 3r Free Standing Stainless Steel Electrical Enclosure

The outdoor weather proof Nema 3R free standing steel electrical enclosure can be a good choice for some electrical equipment protection. If you need a higher Nema rating, KDM can offer you the item as well. Such enclosures are made out of rust resistant steel, and bended in the right shape without hurting the overall strength of stainless steel material. The surface is well polished, so you will notice that the drawing lines are consistent. For more details, contact us now.

Single Door Stainless Steel Free Standing Enclosure with Door Lock and Viewing Window

KDM can offer you the single door stainless steel free standing enclosure with lock and viewing window. The view window can be made out of acrylic, pc, or fire resistant glass. KDM work with one of the largest enclosure hardware supplier in China. In this way, we are able to provide you with all kinds of hardware including locks, hinges, door supports and so on. For details, contact us know.

Stainless Steel Free-Standing Single Door Electrical Enclosures

Stainless steel free standing single door electrical enclosure is one of the most popular enclosures in KDM. Based on the dust and water protection rating, we can make the enclosure up to IP66 rating. For the mounting plate, we can make it based on your requirement with different mounting brackets. For details, contact us right now.

Stainless Steel AE Wall Mount Electrical Enclosure

Stainless steel AE wall mount electrical enclosure is a standard enclosure item. Based on the different working environments, we can provide different mounting brackets and mounting nuts. The gland hole and plate can be made at the bottom or side. You can choose the materials of gland plate, brass, aluminum or steel. All can be custom made with rubber sealing. Email us now for discussion.

Stainless Steel Double Door Free Standing Weather Proof Electrical Enclosure with Door Lock

Stainless steel double door free standing and weather proof electrical enclosure with door lock is a popular item. More than one hundred of locks are available for your selection. For better circulation, we can add right fans at the top or bottom to ensure the inside enclosure working temperature. The earth studs are added in both doors, enclosures, and as well as the gland plates if you require. Ask the quote now with your size.

Stainless Steel Free Standing Dust Proof Electrical Enclosures

Stainless steel free standing dust proof electrical enclosures are made based on good Ip rating standard. If you need the ventilation fan, or louver, we can offer you our best design. In this way, the enclosure can still maintain a good protection against the dust. For electrical equipment buttons, we can do the cutout based on your design. For detailed requirement, please contact us now.

Stainless Steel Free Standing Electrical Enclosure with Locks and Latches

Stainless steel free standing electrical enclosures normally come with locks and latches. For different applications and environments, we can offer you a variety of locks and latches, or padlock items. In addition, we can offer common steel with chrome treatment items, or stainless steel items. In addition, per your request, we can give you options of front door, side door, or rear doors. For details, ask us now.

Stainless Steel Free Standing Electrical Enclosure with Pocket

Stainless steel free standing electrical enclosure is normally with doc pocket. The top part can be equipped with the eye bolts for easy lifting. In addition, we can set the enclosure part with several shelvings and brackets for electrical parts fixture. The front button cutout can be done based on the drawing so that it is easier for you to do the equipment setting up. Ask the price now.

Stainless Steel Free Standing Electrical Panel Enclosure

KDM can custom your stainless steel free standing electrical panel enclosure per your request and standard. Based on the environment, you can decide whether to add the bottom plinth or not. We can make the cutout with gland plate at the bottom for the cable entries. We can also set the side panel with cable entries. For details, please email us.

Stainless Steel Free Standing Enclosure with Door Interlock

KDM can make the stainless steel free standing enclosure with door interlock setting. You can choose the right lock in our recommendations. The bottom side panel can be set with air filter and cover. The wire mesh is outside of the filter or the louver so that the insects can not get it. We can add the window at the front door, so you can easily know the equipment situation. Contact us now.

Stainless Steel Free Standing Industrial Electrical Enclosures with File Pocket

KDM normally add file pocket design for the stainless steel free standing industrial electrical enclosures. For industrial ones, we will use right gauge thickness of stainless steel so that the enclosure is able to support all equipments. Based on different electrical parts, we can add all kinds of suitable fixture brackets. For details, email us.

Stainless Steel Free Standing Modular Electrical Enclosure with Window

Stainless steel free standing modular electrical enclosure with window is a comprehensive enclosure for several features. It is easy to be combined with other enclosures to form a bigger enclosure. The front window is glued onto the front panel so the water can not get in. There is galvanized steel or powder coating shelving in the enclosure. In this way, you can put all your equipments in place.

Stainless Steel Free Standing Vented Electrical Enclosure

Stainless steel free standing vented electrical enclosure is with venting or louver at the bottom of the enclosure. In addition, we can add the cable entries holes near the venting design or at the bottom. The entries holes will be cover by gland plates or rubber seal. For inner equipment parts, we can make the mounting design based on different equipments. If you need advice from us, contact us now.

Stainless Steel IP 66 Weatherproof Free Standing Enclosure

Stainless steel IP66 free standing enclosure is of weatherproof. It can be used indoor and outdoor. Normally we add the window at the front door so that you can see the inner electrical parts working data. To protect the electrical parts, we can add the filter with cover at the bottom of the enclosure. In this way, electrical equipment can work in a good temperature. If you have any other requirements, contact us now.

Stainless Steel NEMA 3 Switch Wall Mount Electrical Enclosure

Stainless steel Nema 3 switch wall mount electrical enclosure is widely used for all kinds electrical parts protection. For your easy operation, we can make the cut out at our side based on your switch size. Of course, if you want to get the standard switch buttons, we can also offer at our end. We can provide galvanized steel mounting, powder coating mounting plate, or bakelite mounting plate for your different usages.

Stainless Steel NEMA 4 Wall Mount Electrical Enclosure

Stainless steel Nema 4 wall mount electrical enclosure is very suitable to be used outdoor. With the stainless steel bracket at the back, the enclosure can be easily fixed onto the wall. Based on the specific applications, we can provide single door, or outside door and inner door design for this enclosure. For details, ask us now.

Stainless Steel NEMA 4x Free Standing Electrical Enclosures with Air Filter

Stainless steel Nema 4x free standing electrical enclosures with air filter is a good combinations between IP rating and also the inner air circulation. It can maintain a suitable temperature in the enclosure to protect the electrical parts. We can add the all kinds of accessories in the enclosure such as the bracket. You can decide the the height, such as 18U and so on. We can make it per your request.

Stainless Steel NEMA 4X Wall Mount Enclosure

Stainless steel Nema 4x wall mount enclosure can be used both indoor and outdoor. It has good protection against the dust and rain. We can add specific cable entries holes at the bottom or side. For better rust resistance, we can also offer the stainless steel brackets to fix the enclosure on the wall. If you need other accessories for fixture, you can check with us by mail directly.

Stainless Steel NEMA Type 4 Free Standing Electrical Enclosures

Stainless steel Nema type 4 free standing electrical enclosure is an enclosure with good resistance to the dust coming through and the water intruding. The base can be made with the plinth and with center cable entry holes. The holes will be covered by gland plate or rubber seals for better dust and water intruding protection. For details, please email or call us.

Stainless Steel Outdoor Free Standing Enclosures for Electrical Equipment

Stainless steel outdoor free standing enclosures are made for different applications of electrical equipments. For the material, based on different environment, you can choose stainless steel 201, stainless steel 304, or stainless steel 316L. For the roof, we can offer you different rain hoods to avoid the water splashing into the enclosures. For details, please inquiry us now.

Stainless Steel Wall Mount Cabinet

Stainless steel wall mount cabinet is the most popular item in KDM. 95% of our goods are custom made. If you want to get the enclosure made, we can do the 3D drawing in 2 days for your confirmation. We can finish the sample in 3-7 days. Video inspection and meeting is available in KDM if you want to check the factory facility and products online. Contact us now.

Stainless Steel Wall Mount Enclosure Cabinet and Box

Stainless steel wall mount enclosure cabinet and box is commonly used for lots of electrical parts protection. KDM can provide stainless steel brackets to fix the cabinet on the wall. In addition, we can also design the electrical parts fixture in the cabinet. If you need flexible fitting, we can also provide you the din rail bracket. For more questions, ask us now.

Stainless Steel Wall Mount Enclosure with Lock

For stainless steel wall mount enclosure, it normally comes with lock. For different Ip ratings, we will give different options of lock. For electrical parts fixture, you can use mounting bracket, or ask us to do the custom bracket. In addition, we will weld the earth stud in door and enclosure part for protection. Ask us the rate now.

Related Product

Ultimate FAQ Guide to Stainless Steel Electrical Enclosures

- What is the standard configuration of an electrical enclosure?

- What is the difference between 304, 316, and 201 stainless steel?

- What is the difference between stainless steel, steel, and galvanized steel enclosures?

- Why do some stainless steel types have letter indications, such as 316L?

- Are there drawbacks to using stainless steel?

- What does gauge steel mean?

- What are some designs of enclosures?

- Besides protection from hazards, what else should I think about regarding stainless steel enclosure design?

- Can I bury the enclosure/install it underground?

- What additional features can electrical enclosures have and what are they used for?

- What is the process of creating my stainless steel electrical enclosure?

- What corrosive chemicals do stainless steel enclosures guard against?

- What are some important properties of stainless steel?

- What IP and NEMA ratings are available for stainless steel enclosures?

What is the standard configuration of an electrical enclosure?

The standard configuration of an electrical enclosure consists of a gland plate, a radiating fan, a fluorescent lamp with a switch, ground connections, and PU foaming seals.

A gland plate is used to cover the base opening, as well as the sides.

This is the visible box, the outer layer that protects the contents of the enclosure.

You need to choose the right material for your gland plate since it will be in direct contact with potential hazards.

Gland plate

A radiating fan helps cool the electrical components of the enclosure.

When these electrical components are running, they often generate heat that can disrupt their work.

Plus, the weather can add to that heat.

In order to prolong the life of wiring components, a fan is necessary.

Radiating fan

A fluorescent lamp with a switch is helpful for any work that will be installing, replacing, or taking care of electrical components.

Ground connections, also known as neutral connections, protect the wiring from voltage jumps.

They provide a path to the ground for electricity, so that any excess can be rerouted there.

This also prolongs the life of your wiring, as well as saves it from short-circuits.

Finally, the PU foaming seal is used as a gasket – to fill in crevices of the enclosure to nothing gets in.

PU stands for the material polyurethane, which is commonly used for gaskets and seals due to its high resilience qualities.

This is how you truly dustproof and waterproof an enclosure.

Usually, these seals are put around the hinges, windows, and doors, or wherever there may be an opening.

PU foam seal (the black line)

What is the difference between 304, 316, and 201 stainless steel?

Steel is an alloy and all of these series of steel differ by composition – percentages of various ingredients that it give it certain qualities.

Stainless steel 304 has 18% chromium and 8% nickel in its mix.

This makes it resistant to oxidation – rusting – and very durable.

This steel has no limitations of where it can be used.

Steel 316 has less chromium, more nickel, and includes an element called molybdenum.

This alloy is the most resistant one to corrosion, as well as chlorine and salt.

This is why it is commonly used in offshore, marine, and washdown applications.

It is also more in demand in the pharmaceutical sector because molybdenum helps avoid contamination from metal.

Finally, 201 stainless steel is characterized by very low levels of nickel, which is why it is cheap.

However, it is not resistant to corrosion, so enclosures from this steel aren’t good for outdoor applications.

All these belong to the austenitic family, which are non-magnetic metals that are weldable at any temperature.

This family can be divided into 2 series: 300 and 200.

You won’t be able to tell the difference between all these steels by just looking at them.

Thus, you will need to check the manufacturer’s report to make sure the right type of stainless steel is used.

To choose the type or grade of stainless steel, consider the qualities you need and go from there.

You can also contact us for a consultation!

What is the difference between stainless steel, steel, and galvanized steel enclosures?

Firstly, regular steel is a mix of iron and carbon, which is why it is also known as carbon steel and mild steel. Steel is strong but prone to rusting and staining.

We can make steel enclosures, but they are not as resistant to corrosion as stainless steel enclosures are.

Stainless steel is modified by adding chromium, nickel, and molybdenum to the iron-carbon alloy.

Steel is usually duller than stainless steel.

It is also magnetic and more malleable.

Galvanized steel is coated with a layer of zinc that gives it corrosion-resistant qualities.

While we do offer galvanized steel enclosures, this metal is vulnerable to salt water.

Keep in mind that galvanized steel is more expensive and heavier than stainless steel.

Stainless vs. galvanized steel

Why do some stainless steel types have letter indications, such as 316L?

In this case, the “L” stands for “low”.

This refers to the carbon content in the alloy.

Stainless steel with the grade 316L has lower levels of carbon than steel 316.

Overall, 316L is slightly more corrosion-resistant, more weldable, and more temperature-resistant.

The cost doesn’t differ much between the two.

The “L” works with other steel grades as well, so talk to your manufacturer, look at lists and graphs.

Are there drawbacks to using stainless steel?

Stainless steel is nearly ideal for electrical enclosure.

The only two things is that stainless steel is expensive upfront, but this drawback is cancelled out by the material’s long-term performance.

What does gauge steel mean?

This refers to the sheet metal gauge, or gage, that measures the thickness of a sheet of metal.

Typically, as the gauge number decreases, the thickness increases.

Stainless steel can go from gauge 7 to gauge 31, which is equivalent to 4.8mm to 0.28mm.

As you would expect, thicker sheets are stronger, but thinner ones are cheaper.

Thus, you should carefully consider your requirements and budget when deciding on the gauge.

What are some designs of enclosures?

Designs for stainless steel enclosures don’t differ from other enclosures we make.

Namely, we offer free-standing enclosures, wall-mounted enclosures, junction boxes/operator interface.

Free-standing enclosures are perfect for large electrical units that are too heavy to be wall-mounted or pole-mounted.

They could be of any height and width.

They are also portable.

Free-standing enclosure

Wall-mounted enclosures use mounting brackets, screws, and pads.

They are perfect for small devices, and thus are cost-effective.

Wall-mounted enclosure

Junction boxes and operator interfaces are usually enclosures on a stand.

They have user-friendly layouts, are great for small electrical units, and can be portable.

Junction box/operator interface enclosure

Plus, different options for doors, including single, double, and multiple doors.

Single doors are perfect for smaller and less complex electrical units, whereas double doors are used for large and complicated units.

Multiple doors are used for huge industrial applications or for increased security.

Besides protection from hazards, what else should I think about regarding stainless steel enclosure design?

Fortunately, stainless steel is a material that won’t give you much trouble at all, so anything else you should think about has to do with the enclosure and its design.

Firstly, think about what environment you’ll be putting the enclosure in: is it hot or cold.

Also think about where it will be mounted, whether it will be serviced a lot, what locks do you need, what handles, do you need vents or windows.

Then, think about the size of the enclosure.

If it is too small, your wiring won’t fit, but if it is too big, you will lose money since not all of the space is used efficiently.

Plus, you should consider the looks of the enclosure as well.

Do you need a certain finish, such as glossy or matte?

Fun fact: the finish can also play a role in protecting the enclosure from corrosive elements.

You can also choose a color.

You are welcome to talk to us and we will provide you with a technical drawing and some advice for free!

Can I bury the enclosure/install it underground?

Stainless steel is very resistant to corrosion, so the soil would not disturb it.

You can then make a door at the top of the enclosure and make it so the electrical components can be taken out easily for maintenance.

Enclosure mounted in the ground

You can also have other recessed enclosures that go into concrete and brick.

What additional features can electrical enclosures have and what are they used for?

Additional features and accessories that we offer include vents, windows, back panels, lifting eyes, rain caps, and file pockets.

Let’s examine how each could benefit your project.

Vents serve the same purpose as radiating fans, providing a path for heat to escape, cooling electrical components of the enclosure.

Windows are used to help workers examine the electrical components in a non-invasive way.

And if something goes wrong, a window helps see right away what is happening.

Another use of windows, infra-red windows help protect personnel from arc flash accidents.

Windowed enclosure

Back panels allow for a convenient way to mount an enclosure securely so that any devices stay in the correct position.

Lifting eyes aid installation.

They are little hooks at the corners of an enclosure that you can use to lift it up for transportation of mounting.

This is especially useful if an enclosure is very heavy and the only way to transport it is by lifting it up.

Lifting eyes

Rain caps are the top parts of an enclosure.

They can be flat, but protruding forth more than the enclosure, or they can be tilted like a roof.

They help divert streams of rain off of the enclosure so the rest of it gets less exposure to the rain.

This prolongs the life of your enclosure.

Rain cap

File pockets are used to store files like operating manuals, shift logs, information booklets, and anything else important that pertains to electrical components within the enclosure.

File pocket (underlined in yellow)

What is the process of creating my stainless steel electrical enclosure?

Firstly, you should consider all your requirements and contact us for a consultation, quote, and drawing.

Once all details are discussed and gear are set in motion, we will provide you with a prototype in just 3 days.

The manufacturing process entails laser cutting, bending, welding, foaming, polishing, and final assembly.

Individual pieces of the design are cut out from sheet metal with a laser.

Then, a machine bends folds and corners of the cutout.

These pieces are then welded together to create the shell of your enclosure.

Foaming refers to the addition of PU foam seals that waterproof the enclosure.

Manufacturing electrical enclosures

The enclosure is then polished for smoothness and better appearance.

Then, we assemble all the pieces: the body of the enclosure, mounting brackets, vents, windows, hinges, lifting eyes, rain caps, any other accessory you have requested.

Finally, we coat the product with your chosen finish or color, usually using powder finishes.

What corrosive chemicals do stainless steel enclosures guard against?

Some harmful chemicals include sulfuric acid, various chlorides, bromides, iodides, and fatty acids at high temperatures.

All these may be present in factories and other industrial applications.

Such include petroleum refinery, production of fertilizers and medication, as well as assembly of batteries, laboratories, and mining facilities.

What are some important properties of stainless steel?

Some important properties that are useful for electrical enclosures include corrosion resistance, cryogenic toughness, higher work hardening rate, ductility, low maintenance.

Corrosion resistance, of course, is a crucial property of stainless steel that is necessary for electrical enclosures in certain environments.

Cryogenic toughness refers to how tough the metal is at low and sub-zero temperatures.

Stainless steel actually becomes stronger in colder environments, whereas some other types of steel become weak.

This property makes stainless steel perfect for marine and freezer applications, as well as in cold parts of the world.

On the other end of the spectrum, stainless steel also stays strong in hot temperatures as well.

Rods of stainless steel

Work hardening rate tells you how much a material can be strengthened through cold working and annealing.

Stainless steel, since it has a cryogenic advantage, can be strengthened a lot with cold.

Ductility means that the material can be stretched out a lot.

Thus, stainless steel is easier to work with, while maintaining its strength.

Finally, low maintenance means that personnel won’t have to tend to the enclosure, but rather spend their valuable time checking the electrical components within said enclosure.

What IP and NEMA ratings are available for stainless steel enclosures?

IP rating and NEMA types do overlap a little, and while it is not possible to translate one directly into another, it is possible to somewhat line them up.

Relationship between NEMA and IP