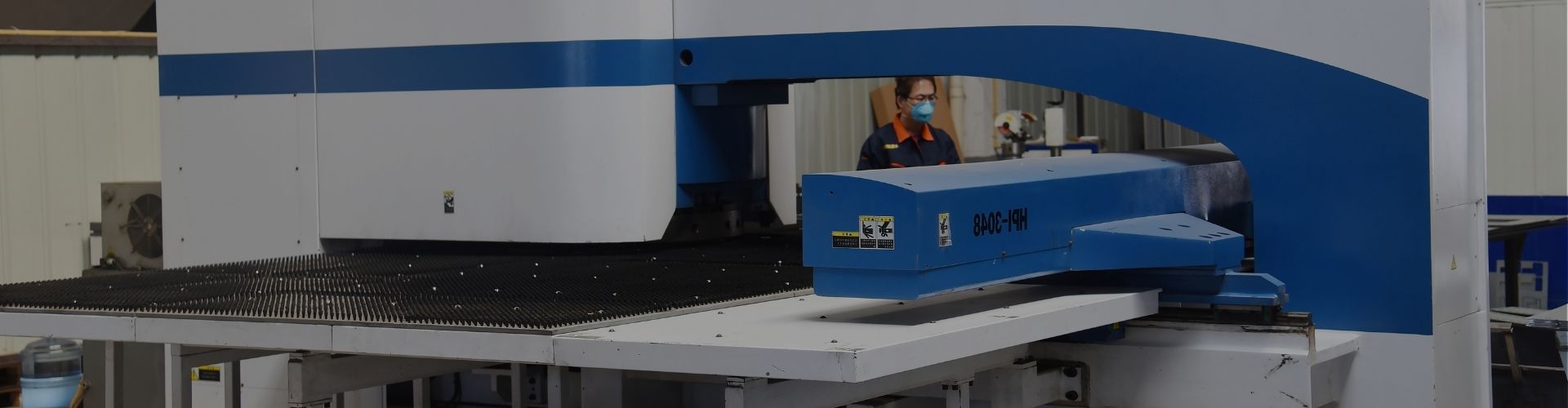

KDM Electrical Enclosure Laser Cutting

Electrical enclosure laser cutting is one of the core fabrications services we offer at KDM Steel.

The process involves using a laser cutting machine utilizing a high-power laser directed through optics and computer numerical control to direct material or beam.

Ideally, our electrical enclosure laser cutting process uses a motion control system to follow a CNC pattern cut on the component.

It allows the focused laser beams to burn, melt, vaporize, and blown away a jet of gas.

This leaves an ultra-quality surface-finished edge of the electrical enclosure.

We create the laser beam by stimulating lasing materials through electrical discharges.

The lasing component is amplified by being reflected internally through a partial mirror until it gets enough energy to escape as steam of coherent monochromatic light.

The light is deliberately focused at the electrical enclosure’s work area by fiber optics directing the beam through a lens to intensify it.

Types Of KDM Steel Electrical Enclosure Laser Cutting

At KDM steel, we offer a wide range of laser cuttings to different electrical enclosures.

Essentially, every electrical enclosure has different structural properties, thus require different forms of laser cutting.

Nonetheless, we specialize in three major techniques of laser cutting for electrical enclosures, which include the following;

- Carbon dioxide laser

- Neodymium (Nd)

- Neodymium yttrium-aluminum-garnet (Nd:YAG)

Stainless steel laser cutting

CO2 laser cutting involves passing a current through a gas mix, often known as DC-excited.

It also entails using a relatively new technique of radiofrequency, commonly known as RF-excited.

The RF technique has external electrodes, thus prevents issues related to electrode erosion.

Common variants of CO2 that KDM use include slab, transverse flow, slow axial flow, and fast axial flow.

Our fast axial flow utilizes a mixture of nitrogen, helium, and carbon dioxide circulated at a high velocity by a turbine.

Slab or diffusion resonators use a static gas field that requires zero pressurization.

Why You Should Consider KDM Steel Electrical Enclosure Laser Cutting

Technically, our laser services revolving around cutting electrical enclosures offer a wide range of benefits.

We provide laser cutting services for electrical enclosures that give you value for money.

Some of the reasons you need to consider us for such services include the following;

- Flexibility – Our electrical enclosure laser cutting services do not require any form of tools exchange for each different cut.It means the same setup is used for cutting different electrical enclosure designs into various shapes within similar material thickness.Therefore, we guarantee desired results irrespective of the possible intricacies.

- Faster speed – At KDM steel, we provide relatively faster electrical enclosure laser cutting services, which can rarely find elsewhere.Essentially, this is important, particularly for enclosures cut in complex shapes.This service makes it easy to cut through electrical enclosures with different thicknesses comparatively fast.

- High accuracy and precision cuts – At KDM steel, we use a powerful laser that delivers a concentrated beam of light to the electrical enclosure.This makes it possible to deliver extreme precision cuts, which is essential in attaining accuracy when fabricating this component.

- Causes zero damage or warping – Irrespective of the wall thickness of the electrical enclosure, we ensure the final product has no distortion or warping.Of course, this is vital, especially when cutting relatively thin electrical enclosures.

- Better material utilization – Our laser cutting services guarantee the ideal utilization of your sheet material when making electrical enclosures.We use this to maximize the number of usable components and parts from any particular sheet of material.

Cost Of Electrical Enclosure Laser Cutting At KDM Steel

Surprisingly, KDM steel offers electrical enclosure laser cutting services at cost-friendly rates. In most instances, we price the service based on various prevailing factors.

Majorly, the actual cost we charge is based on the duration it takes to complete the task.

We also charge this service based on the size of the electrical enclosure.

The type of material is another vital element we consider when pricing the cost of electrical enclosure laser cutting.

Cost for numerous kinds of steel materials, such as carbon steel and stainless steel among others, vary.

The material thickness also determines the price of laser services we offer for cutting electrical enclosures.

Most importantly, the quantity of electrical enclosures you need cut also determines the actual amount we charge for laser cutting services.

Ideally, the average laser cutting service for electrical enclosures ranges from $13 to $20 per hour.

However, this is often dependent on different factors, including the above-mentioned ones among others.

Elements That Make KDM Steel Stand Out In The industry

Ideally, KDM steel as a professional outfit offers electrical enclosure services, which suit your specific requirements.

In essence, it allows you to get the specific electrical enclosure with exact dimensions and even smooth edges.

We have a wide range of advanced laser cutters, which conform to all the industrial and quality standards.

This is important because it allows us to execute all the laser cutting processes effectively on your electrical enclosure.

Larger electrical enclosures can easily fit into our laser cutting machine.

At KDM Steel, we offer a relatively fast turnaround time of about 4-7 days, depending on the order quantity.

Immediately the drawing and designs are approved, the turnaround for small and medium order can take up to four working days.

Of course, this is crucial since it enhances convenience and allowing you to work on your electrical project as soon as possible.

Moreover, if you have an urgent order, let us know, and we’ll arrange for something for your convenience.

You can always supply your materials and electrical enclosures to us for laser cutting.

Essentially, not all types of electrical enclosures are laser-friendly.

Thus you’ll need to provide us with details of the specific material of your electrical enclosure.

It allows us to advise you if we can work with such electrical enclosures.

If the material of your electrical enclosures is something we have never come across before, we’ll have to test it on our machines.

This allows us to establish optimum cutting settings.

Moreover, we can supply you with a sample of your artwork for your approval.

In a nutshell, KDM Steel is the best service provider for all your electrical enclosure laser cutting solutions.

Feel free to get in touch with us for more information.