- Customized NEMA Enclosure Solution

- IP65/IP66 Certification

- Fast Enclosure Sample Production

Custom NEMA 4 Enclosure Manufacturer in China

NEMA 4 enclosures are generally gaskets with doors that clamp to provide maximum sealing. Same as NEMA 3 but adds protection against hose-directed water. Designed to protect against all types of weather and direct hose blasts in factory washdown environments, these enclosures must use a closed-loop cooling system to ensure that no contaminants enter the unit. KDM NEMA 4 enclosure can be used for both breaths of air to air heat exchangers or air conditioners based on the ambient temperature surrounding them.

KDM NEMA 4 enclosure offers the best solution for both your outdoor and indoor projects. The NMEA type 4 enclosures provide extra protection against harmful effects on the electrical components due to splashing water, as well falling dirt, rain, sleet, snow, windblown dust, and hose-directed water.KDM ensures our NEMA 4 enclosures are ideal for housing sensitive electronic assemblies in your environments.

KDM NEMA 4 Enclosure Series

Send your Inquiry on KDM NEMA 4 Enclosure

KDM offers a wide selection of NEMA 4 enclosures. However, it is important that you choose a NEMA 4 enclosure according to your project requirement. Including the right dimensions, suitable sizes, and design. At KDM, we provide the specific equipment you need to ensure that your NEMA 4 enclosure meets the recommended standards and keeps your valuable equipment protected. KDM, as an industry reliable and reputable manufacturer of all kinds of enclosures, we provide each NEMA 4 enclosure, with the standards that meet your satisfaction with speed, accuracy, and reliability.

- Manufacturing Capacity

- Buying Guide

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experience workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

Expert assembling team, consistent assembly quality on every KDM enclosure

KDM NEMA 4 Enclosure

NEMA 4 enclosure is not different from the other types as it provides a high level of protection to users against incidental contact with the enclosed equipment. Whether you are in a commercial or industrial environment, KDM NEMA 4 enclosure offers outstanding protection from the elements in your area. At KDM, we are glad to provide you a quality NEMA 4 electrical enclosure at a competitive price.

KDM NEMA 4 enclosure commonly used in industrial applications for wiring enclosures, hydraulic controls, and operator consoles as it is a watertight type of enclosure. Also, if the equipment is directly exposed to the sunlight, KDM NEMA 4 enclosure is your best choice.

NEMA 4 enclosure

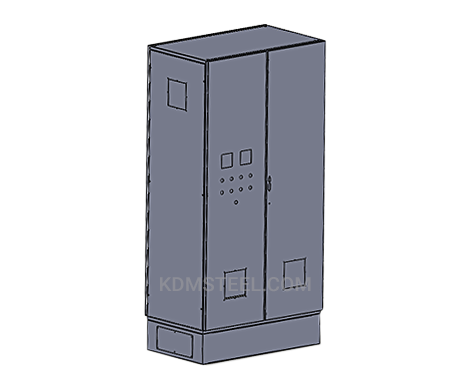

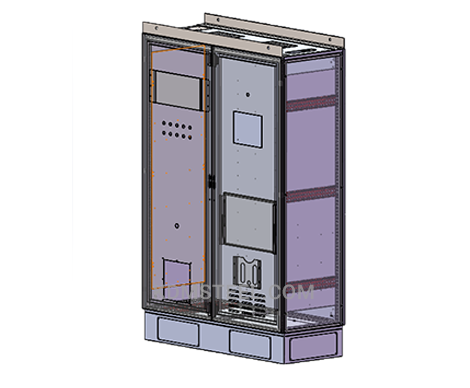

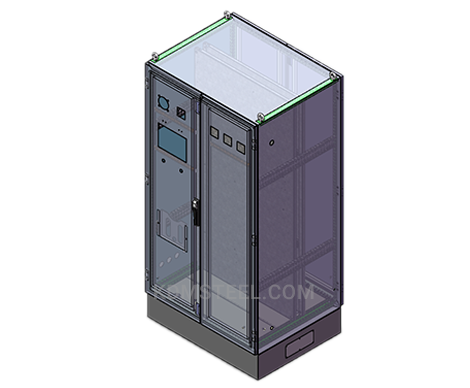

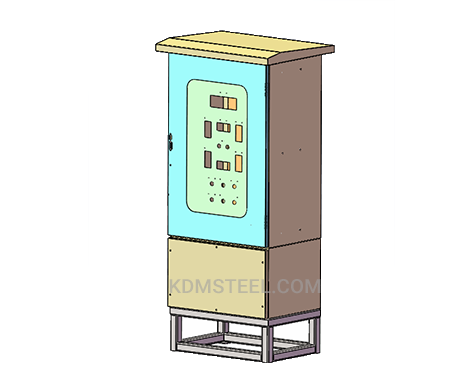

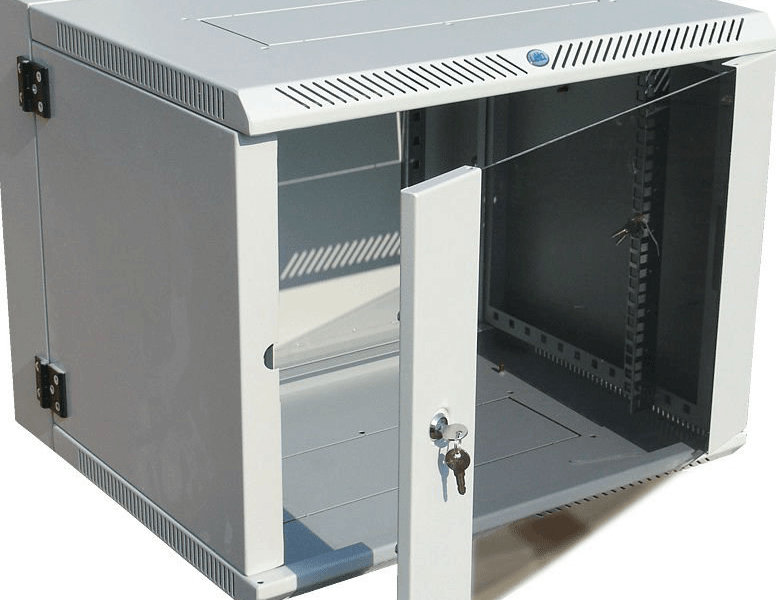

https://youtu.be/sp-6BlAQkzk KDM manufacture NEMA 4 enclosure available in sizes ranging from small wall mounts to two-door floor mount models from a variety of metals depending on your specific application. They can also be equipped with continuous hinges, mounting feet, and padlock hasps.  Our NEMA 4 enclosures are available in a variety of types, such as wall-mounted, free-standing, etc. In addition to this, you can custom pre-punched holes, cutouts, lift-off hinges, insulation, latches or locks available. With KDM NEMA 4 enclosure, you can guarantee top-grade electrical enclosures, as KDM strictly adheres to the exact NEMA standards. We can expedite a custom enclosure and produce cost-effective NEMA 4 enclosure to keep safe your electrical components. From small businesses to multinational corporations, At KDM, we are committed to fulfilling each of our customer’s expectations through our top quality NEMA 4 enclosures and exceeding customer service. With over 10 year’s expertise in manufacturing enclosure, all our clients got the best NEMA 4 enclosure solutions for their various needs.

Our NEMA 4 enclosures are available in a variety of types, such as wall-mounted, free-standing, etc. In addition to this, you can custom pre-punched holes, cutouts, lift-off hinges, insulation, latches or locks available. With KDM NEMA 4 enclosure, you can guarantee top-grade electrical enclosures, as KDM strictly adheres to the exact NEMA standards. We can expedite a custom enclosure and produce cost-effective NEMA 4 enclosure to keep safe your electrical components. From small businesses to multinational corporations, At KDM, we are committed to fulfilling each of our customer’s expectations through our top quality NEMA 4 enclosures and exceeding customer service. With over 10 year’s expertise in manufacturing enclosure, all our clients got the best NEMA 4 enclosure solutions for their various needs.

The Definitive FAQ Guide to NEMA 4 Enclosures

- What does NEMA Type 4 mean?

- How is NEMA 4 different from NEMA 4X?

- Are NEMA 4 enclosures used outdoors?

- What are common applications for NEMA 4 enclosures?

- What is the standard NEMA 4 enclosure configuration?

- How are NEMA 4 enclosures tested?

- How can I be sure of the quality of NEMA 4 enclosures?

- What is NEMA 4 in IP standards?

- What are common designs for NEMA 4 enclosures?

- What additional features are often included?

- Do knockouts, vents, fittings, etc. affect the rating of the enclosure?

- How do NEMA 4 enclosures maintain the thermal environment?

- What materials are used for NEMA 4 enclosures?

- What paints and coatings can be used for NEMA 4 enclosures?

- What are some ways to put symbols on a NEMA Type 4 enclosure?

- What common mistakes should I be aware of when ordering a NEMA 4 enclosure?

What does NEMA Type 4 mean?

NEMA stands for National Electrical Manufacturers Association.

Type 4 enclosures protect personnel from accidental contact with live parts, as well as protect the equipment from windblown dust, rain, snow, ice, and hose-directed water.

Basically, it offers the same qualities as NEMA 3, except for improved protection against water ingress.

It is often marked as ‘watertight’.

This is due to NEMA Type 4 enclosures having more PU gaskets than Type 3, as well as having more welded parts.

NEMA 4 enclosure

This means that you can install it in places with lots of splashing water, and wash the enclosure with a hose if needed.

How is NEMA 4 different from NEMA 4X?

NEMA 4X is the same as NEMA 4, except it offers extra protection against corrosive agents, such as alkaloids, acids, and solvents.

Usually, this is due to materials used.

Are NEMA 4 enclosures used outdoors?

Yes, they are.

NEMA 4 enclosures are very often used outdoors, as well as indoors in industrial places.

Because of the type’s protection against water ingress, it is perfectly suitable for the outside.

What are common applications for NEMA 4 enclosures?

NEMA 4 enclosures are used mainly for commercial and industrial applications.

These include electrical hydraulic or pneumatic control box, terminal or junction wiring enclosures, operator interfaces.

NEMA 4 enclosures also house IT equipment, telecom wiring, security, and communications signal equipment.

Because of this type’s resistance to water these enclosures are often found in marine or naval applications.

Some industrial applications may include transportation industries, paper mill industry, and various municipalities like water treatment plants.

Commercial applications may be diaries, breweries, and such.

For more information, check out our NEMA enclosure FAQ!

What is the standard NEMA 4 enclosure configuration?

The standard configuration we provide is a gland plate with modules for cable entry, ground connections, fluorescent lamp with a switch, a radiating fan, PU gaskets.

NEMA 4 enclosures should also be marked that they require waterproof fittings, conduit connections, and mounting hubs.

You can also request any other feature you need.

How are NEMA 4 enclosures tested?

NEMA enclosures are not tested by NEMA, but by third-party laboratories.

However, you can refer to the latest NEMA 250 document for requirements of self-declaration of NEMA labels.

NEMA 4 is tested using the external icing test, the hosedown test, the outdoor corrosion test, and the gasket test.

External icing test involves spraying the enclosure with water and then cooling down the room until 20mm of ice has formed over the enclosure.

External icing test

The enclosure should be undamaged and operable at the end of the test.

Outdoor corrosion test involves making a 5% sodium chloride solution and spraying it onto the enclosure continuously for 600 hours (25 days).

The hosedown test sprays water at a rate of 240 liters per minute from 10 feet, for 5 minutes straight.

Hosedown test

Passing this test gives automatic pass on the rod entry test and the rain test.

NEMA 4 enclosures also undergo various gasket tests to evaluate how they age while stretched at high temperatures.

As long as there are no cracks, deformations, and the tensile strength remains the same, the enclosure passes this test.

It is needed because good gaskets are key to good protection against water ingress.

Gasket

How can I be sure of the quality of NEMA 4 enclosures?

At KDM, we have the ISO9001 certification that you can look through.

Also, you can do independent third-party testing of the enclosures if you want confirmation of quality and conformity assessment.

What is NEMA 4 in IP standards?

Although it is difficult to translate one set of standards into another, NEMA Type 4 is roughly comparable to IP55 and IP66.

Both provide very good protection against dust and water, which is why this NEMA type is among the types used most often.

NEMA and IP

What are common designs for NEMA 4 enclosures?

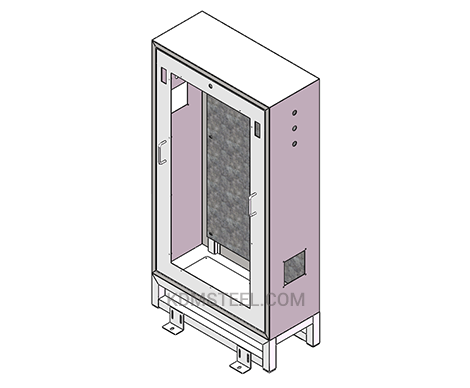

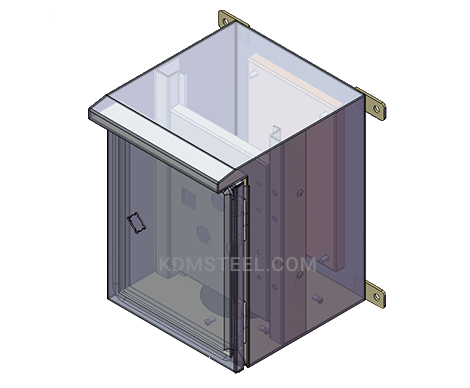

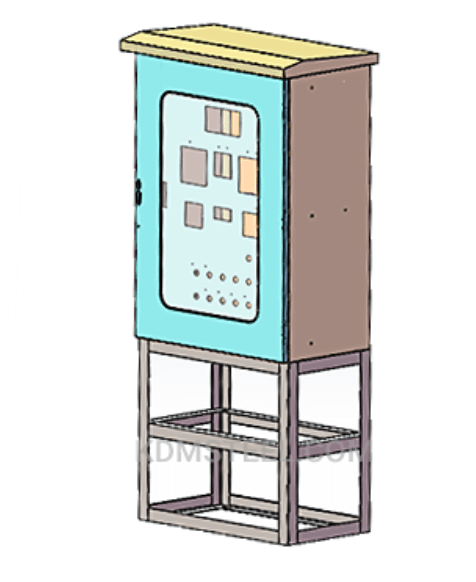

Some common designs for NEMA 4 enclosures include free-standing, floor-mounted, wall-mounted, modular, and custom.

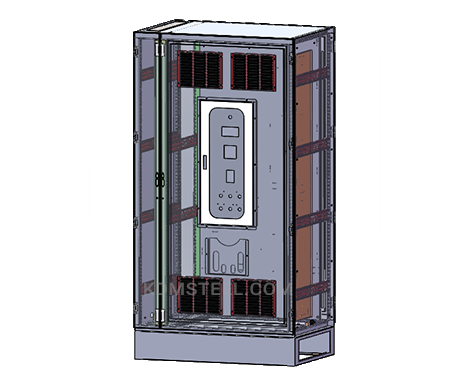

Free-standing, floor-mounted, and walk-in enclosures are used for bigger equipment.

They can have one or multiple doors, depending on your requirements.

Such enclosures can also have pedestals, casters, leveling feet, and lifting eyes to help install and move it around.

Free-standing enclosure

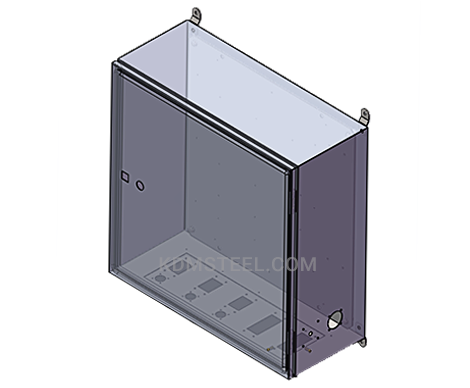

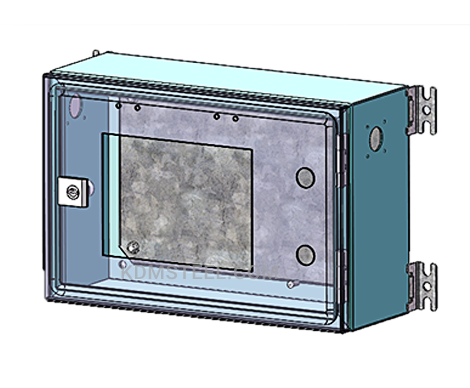

Wall-mounted and pole-mounted NEMA 4 enclosures are typically small and house fuses and switches.

These are less mobile, but take up less space as well.

They are installed using special brackets that can be just external or have internal elements too.

Wall-mounted enclosure

Modular enclosures are those that you can change the shape of, making them flexible in construction and modification.

These are great for NEMA 4 enclosures because that broadens their application.

Modular enclosure

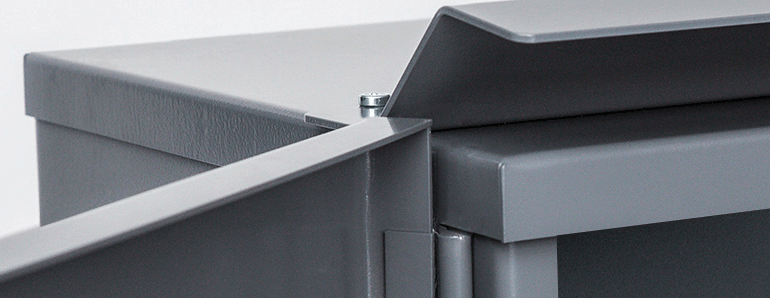

Overall, higher NEMA ratings benefit from U-shaped designs since those require less seam welding, which works well with ice and corrosion protection.

U-shaped enclosure

Of course, we also offer custom enclosures.

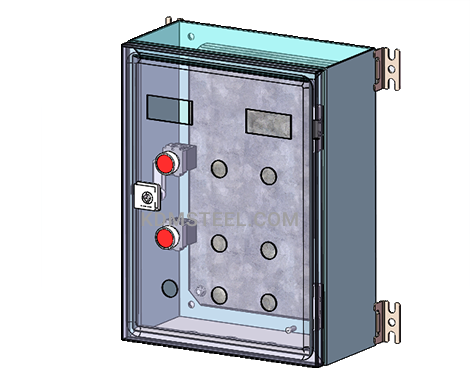

What additional features are often included?

You can request vents, windows, hinged doors, locks, cable management systems, and much more.

Vents, as well as radiating fans, provide a path for heat to escape through, cooling electrical components of the enclosure.

Vents provide a more passive flow of air, whereas fans actively move air and are used to cool down equipment that heats up quickly.

Radiating fan in an enclosure

These also stabilize air pressure inside the enclosure, preventing condensation which can damage the electrical components of the enclosure.

Plus, vents and fans can be further upgraded to air conditioners and heat exchangers.

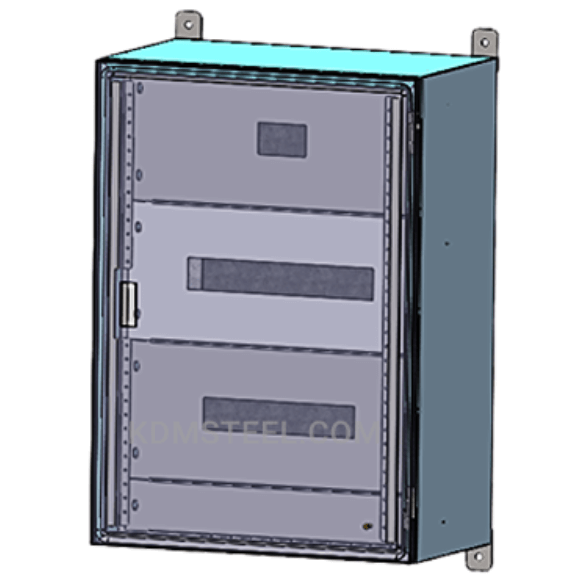

Windows help personnel examine the electrical components in a quick and non-invasive way.

And if something goes wrong, a window helps to see what is happening right away.

Enclosure with a window and a lock

NEMA 4 enclosures benefit from continuous hinges since they minimize gaps that water can enter from.

Locks, latches, and clamps add a layer of security to your NEMA 4 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Clamps go well with NEMA 4 enclosures since they pull the door closer to the body of the enclosure, ensuring minimal water ingress.

We also offer secondary features like casters, lifting eyes, file pockets, rain caps, cable management systems, switches, lights, and anything else you request.

Rain cap

Casters help move the enclosure around; lifting eyes are for heavy enclosures that need to be lifted to be carried around; file pockets store operating manuals; drip caps protect the enclosure from splashing water; solar shields protect against UV rays; switches and lights help personnel do maintenance work on the equipment.

Solar shield

Do knockouts, vents, fittings, etc. affect the rating of the enclosure?

All these weak spots are taken into account, and all of them individually should have the same rating as the entire enclosure.

If one fitting has a lesser rating, the rating of the enclosure goes down as well.

How do NEMA 4 enclosures maintain the thermal environment?

Generally, enclosures can have air conditioners, coolers, heat exchangers, and heater strips to control the temperature inside the enclosure.

This is done to prevent overheating, but also freezing of equipment.

If cold environments are your concern, then heat exchangers and heater strips may be of interest to you.

Heat exchangers are closed loop systems that are easy to maintain.

They push hot air in colder compartments, which results in an equalized temperature and pressure.

Heat exchanger

Heater strips use electricity to heat up the air inside the enclosure to protect its contents from low temperatures, condensation, and subsequent corrosion on the inside.

Enclosure heaters range in performance from 50 to 1200 Watts, depending on the size of your enclosure.

To cool an enclosure down, there are vents and fans that circulate air.

Also, there are air conditioners that cool the incoming air.

Plus, some enclosures have moisture control that dehumidifies air to 30-50% in order to protect the electrical components.

This is especially useful for NEMA 4 enclosures since they are common in humid environments with lots of splashing and hose-directed water.

Enclosure with moisture control

What materials are used for NEMA 4 enclosures?

The materials used for NEMA 4 enclosures aren’t different from materials used for other types of enclosures.

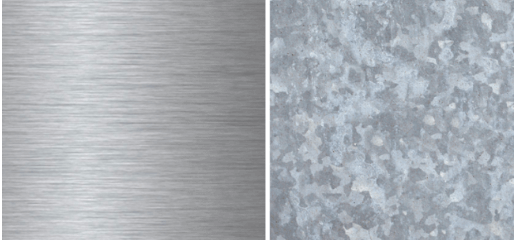

They can be made from carbon steel, galvanized steel, and stainless steel – usually of the grades 304 or 316.

Carbon steel is usually duller than stainless steel.

It is also magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion, so it is not recommended for NEMA Type 4.

Stainless steel is created by adding chromium, nickel, and molybdenum to the iron-carbon alloy.

Stainless steel vs. galvanized steel

Steel grades 304 and 316 differ in the content of all additives.

Galvanized steel is coated with a protective layer of zinc that prevents corrosion.

This type of steel is more expensive and heavier than stainless steel.

Another type of steel that can be used is cold-rolled steel, which is thinner and denser than normal steel – and thus, it is stronger.

When using steel, the manufacturer should keep in mind a certain gauge, or thickness, of the sheet metal that is necessary to comply with NEMA standards.

NEMA 4 enclosures use 14 gauge steel, which is about 2 mm.

Enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys, but can be depending on what you are going for and what are your needs.

Just like steel grades, aluminum alloys can be either of the 5052 or the 6061 series.

Aluminum vs stainless steel

Both are lightweight, but 5052 is more weldable, whereas 6061 has a higher resistance to corrosion.

Also, 6061 is more expensive.

Aluminum has a layer of oxide on top that prevents any corrosion.

This material is especially good for enclosures exposed to solvents, petrochemicals, some acids, most sulfates and nitrates.

For NEMA Type 4 enclosures, stainless steel grade 304 and aluminum are most recommended.

Also, our windows are made from polycarbonate and ABS.

Polycarbonate is more resistant to corrosion, whereas ABS is cheaper.

If you would like to learn more, send in your inquiry now for a consultation!

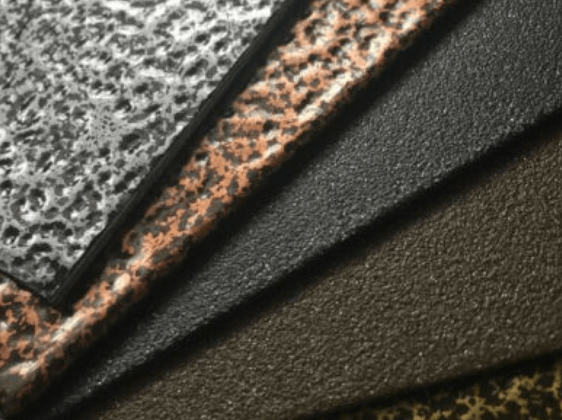

What paints and coatings can be used for NEMA 4 enclosures?

Our enclosures are well-protected, but the right coating can add its protection as well.

You can choose enamel or powder paint coats in any color.

Enamel paint has a glossy finish and is weather-resistant.

Powder paint is deposited with the electrostatic force, and is quicker and easier than enamel.

It is also more flexible in appearance, giving you the option of glossy and matte finishes.

Powder coating finishes

There can also be anti-graffiti and anti-poster coatings to protect your enclosure from vandalism if you plan to install it outdoors.

NEMA 4 enclosures most often use powder coating, but epoxy enamel and PU enamel are also great for industrial enclosures.

We can provide any coating in any color and finish, so contact us today!

What are some ways to put symbols on a NEMA Type 4 enclosure?

Our customizing services include engraving and silk-screening.

If the equipment has to be installed in a particular orientation, this has to be marked on the enclosure.

Also, areas where live parts will be also has to have a mark.

Any warning or danger signs should also be engraved or silk-screened onto the enclosure as well.

Silk Screening is the easiest and most affordable method of customization.

Any flat side of the enclosure can be silk-screened with labels, warnings, serial number, your company name and logo.

However, silk-screening on stainless steel or aluminum can be worn off or scratched off, but a clear powder coating helps to prevent that.

Thus, silk-screening may not be the best for NEMA 4 enclosures.

S

ilk-screening

Engraving the enclosure is another method of customizing your enclosures.

A little bit of metal is removed from the surface of the enclosure in the design of the logo or symbol.

Usually, about 0.005 inches or 0.010 inches of metal is removed from the surface.

Once the metal has been removed, it is filled in with epoxy paint of any color to match your requirements.

This option may be better for NEMA 4 enclosures because it is more long-lasting.

Engraving

What common mistakes should I be aware of when ordering a NEMA 4 enclosure?

Some common mistakes that people make include choosing the wrong NEMA type, wrong material, wrong size, wrong design, and disregarding features.

NEMA types have certain environments they are suited for.

NEMA 4 is built for non-hazardous, indoor and outdoor locations with dust, rain, snow, ice, and hose-directed water.

NEMA 4 usually uses stainless steel 304 or aluminum to increase resistance to outdoor corrosion.

The size and the design of the enclosure depend on the specific electrical equipment you plan to house there.

Industrial enclosures tend to be big, but they don’t have to.

As for the design and features, these are case-specific, so consult your manufacturer for advice.

Recent NEMA 4 Enclosure Order

What is A NEMA 4 Enclosure?

NEMA 4 enclosure is a weatherproof or water-tight enclosure built for outdoor and indoor use.

It provides a high level of protection against falling dirt, windblown dust, airborne dust, circulating dust, falling dust, and other solid objects.

Relatively, NEMA 4 enclosure provides protection from water ingress, light splashing, dripping, hose-down, and splashing water.

NEMA 4 enclosures are available in a variety of types.

It includes JIC, freestanding, and wall-mounted.

Additionally, most NEMA 4 enclosure is gasketed with clamped doors for a maximum seal.

NEMA 4 enclosures are equipped with the following:

- Mounting feet

- Continuous hinges

- Padlock hasps

What is the Characteristic of NEMA 4 Enclosure?

Below are the characteristics of the NEMA 4 enclosure:

- Outdoor or indoor applications

- Protects equipment from rain and windblown dust inside the enclosure

- Protects electrical components from hose-directed water and splashing water

- Protection of ice forming damage

- Custom cutouts, pre-punched holes, locks, latches, insulation, lift-off hinges

- Provides a high level of protection to workers against hazardous parts accessed

What is the Difference Between NEMA 4 Enclosure and NEMA 4X Enclosure?

NEMA 4 enclosure is often utilized for its element protection.

It includes ice formation and cold weather outside the enclosure.

This enclosure is the lowest-rated dustproof among NEMA enclosures.

But it provides extra protection.

NEMA 4X enclosure is often waterproof but can’t be submerged in water.

Nevertheless, the NEMA 4X enclosure should be intense water spray resistance without any water ingress allowed.

What is the Disadvantage of NEMA 4 Enclosure?

NEMA 4 enclosure is not explosion-proof.

Therefore, it is not applicable for hazardous applications.

What Are the Accessory Options for NEMA 4 Enclosure?

Below are the accessory options for NEMA 4 enclosure:

- Switches

- Lights

- Power panels

- Fuse blocks

- Leveling feet

- Casters

- Viewing windows

- NEMA 4 rated A/C units

- Heaters

- Thermostats

- NEMA 4 rated wash-down for fan assembly

What is the Application of NEMA 4 Enclosure?

NEMA 4 enclosure is the solution for different applications, such as:

- Industrial application

- Commercial application

- Military application

What is the Size of NEMA 4 Enclosure?

The NEMA 4 enclosure is available in different sizes.

You can avail yourself of small boxes and large free-standing enclosures, suitable for different applications.

What is NEMA 4 Enclosure Made of?

NEMA 4 enclosure can be available in stainless steel, steel, aluminum, and plastic.

However, most manufacturers use excellent grade carbon steel to construct NEMA 4 enclosures.

It comes with various finishes, such as durable powder coated and oven-baked.

The standard door turn knobs and door handles of this enclosure is powder-coated.

However, you can request your manufacturer to upgrade it to your specific materials with interesting features.

Is NEMA 4 Enclosure Similar with IP65 Enclosure?

IP ratings and NEMA aren’t identical.

They are similar and sometimes be interchangeably used for rating enclosure’s purposes in industrial environments.

IP ratings are primarily determined for liquid or solid foreign objects protection.

NEMA ratings also determine corrosive agents and other conditions protection.

| NEMA RATING (US) | = | IP RATING (International) |

| 1 | = | IP20 |

| 2 | = | IP22 |

| 12 | = | IP54 |

| 4 | = | IP65/IP66 |

| 4X | = | IP65/IP66 |