- Custom Industry enclosure

- IP65/IP66 Certification

- Low MOQ from 1 PC

Custom KDM Steel Enclosure

- Cost-effective enclosure solutions

- Consistent build quality

- Powder coating option

- Customizable structures for specific applications

KDM Instrument Enclosure Series

Send your Inquiry on KDM Instrument Enclosure

KDM Instrument Enclosure is used in many industries such as medical, aviation, manufacturing, production, power generation, etc. The instrument enclosure box helps to put instruments together in instrumentation and automation in PLC, DCS, or SCADA systems while protecting instruments from corrosion and mechanical abuse.

Depending on the design, KDM Instrument Enclosure houses single or multiple instruments, including pressure gauges, sensors, transducers, temperature sensors, etc.

- Manufacturing Capacity

- Enclosure Designs

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experienced workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

The expert assembling team, consistent assembly quality on every KDM enclosure

KDM: Your Professional Instrument Enclosure Manufacturer

KDM Instrument Enclosure has a range of door locking mechanisms, preventing unauthorized access, with handles for easy opening of the door.

KDM Instrument Enclosure, also called an electronic instrument enclosure or instrument enclosure box, is made from steel, stainless steel (304 or 316L), or galvanized steel. It is specifically designed to protect instruments, alongside other electronic instruments from damage.

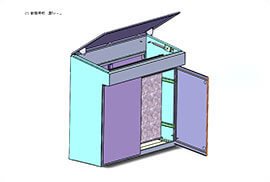

Moreover, these instrument enclosure boxes have flat or sloping roof panels and compartments for installing instruments. To protect instruments from overheating, KDM Instrument Enclosure has a ventilation system for free flow of air thereby cooling instruments.

Also, for easy monitoring of operations, KDM Instrument Enclosure features a polycarbonate window for monitoring instruments, without necessarily opening the instrument enclosure box.

The NEMA rated KDM Instrument Enclosures are suitable for different environmental conditions, talk of either hazardous or non-hazardous environment, there is a design that meets your specific applications. KDM Instrument Enclosure is rated, IEC, CE, and RoHS certified.

With over 10 years of experience in the instrument enclosure manufacturing industry, KDM Steel produces standard and custom instrument enclosure box. Our instrument enclosures are precisely machined and tested to meet high-quality standards.

The KDM Steel engineers’ team carefully chooses the material and technology for manufacturing all instrument enclosures.

For OEM or custom instrument enclosures, the engineers help in design concept and CAD drawing, while helping in material specification and size of the enclosure.

At KDM Steel, we understand the need for keeping all instruments safe, while making your business competitive. Feel free to contact us for custom made and affordable instrument enclosures.

Instrument Enclosure – The Definitive FAQ Guide

Due to the fast progress of human technologies, new types of instruments and various electronic devices arise each year.

In the vast majority of cases, these items require special means of storage, including cabinets and enclosures.

Continue reading if you wish to learn more about instrument enclosures, their types, properties, and so on.

- What Is An Instrument Enclosure?

- What Kind Of Tools Can Be Stored Inside The Instrument Enclosure?

- What Types Of Instrument Enclosures Can KDM Offer?

- What Is A Remote Instrument Enclosure?

- How The Instruments Are Mounted Inside The Instrument Enclosure?

- What Materials Are Used When Making Instrument Enclosures?

- What Kind Of Extra Accessories Can I Order With Instrument Enclosure?

What Is An Instrument Enclosure?

Instrument enclosure is quite a broad concept that can be mentioned in a wide array of instrument applications named further.

In general, an instrument enclosure is a cabinet that is used to safely store vital instruments that require a special containment regime.

A good example is a medical instrument, that has to be protected from environmental influence all the time.

If not, it can cause harm to someone’s health.

All instrument enclosures might be custom-contoured to the shape of the device and designed to provide shock absorption if such a thing is needed.

Desktop instruments can generally be housed in a box-like enclosure that is manageable in size and durability, protecting against spills and accidental contact.

Electronic instruments are used in many applications, especially for precision work in scientific, engineering, medical and technological fields.

Also, they are used to produce jewelry, various wood and stone items, etc.

New ways of making enclosures safe and effective are constantly being researched due to the high demand and crucial nature of some electronic instruments.

The exact parts of an instrument enclosure vary depending on the application.

What Kind Of Tools Can Be Stored Inside The Instrument Enclosure?

Instrument enclosures are used to store a wide range of tools from various industries.

The only thing that connects them is the need for thorough and constant protection of such equipment.

The possible instrument uses include:

- control panels;

- operation switches;

- transmitters;

- measuring and testing devices (for example, psychrometer, thermometers, hygrometers, thermograph, dew cells, barometers, etc.);

- medical tools;

- construction tools;

- peripheral instruments;

- various interface displays;

- communication devices;

- laboratory equipment.

What Types Of Instrument Enclosures Can KDM Offer?

# 1. Field-mounted instrument enclosure

Field-mounted enclosures are designed to meet standards for enclosing indoor and outdoor electronic instruments approved for use in a variety of hazardous locations.

In general, such enclosures are resistant to ultraviolet rays and chemicals.

Their high-impact structure protects instruments even in harsh field conditions.

# 2. Insulated instrument enclosure

In some cases, additional insulation measures are a must, especially when it comes to applications connected with a risk of water getting inside.

Thus, KDM specialists have created a special line of insulated instrument enclosures that utilize the unique sandwich-construction technique, with GRP (glass reinforced polyester) skins enclosing a thick layer of insulating foam.

This helps to achieve a highly efficient solution for protecting against frost and condensation and/or providing regulated temperature environments for sensitive instruments.

# 3. GRP instrument enclosure

GRP is short for glass reinforced polyester.

This material has strong qualities when it comes to the protection of instruments, and also it is the most lightweight solution on our list.

If you do not require an enclosure that has to be strong against various physical impacts than this material is the best choice for you.

Also, it has good conductivity properties and can be used for a long period of time.

# 4. Marine instrument enclosure

The better part of maritime transport requires the use of various instruments.

Thus, the use of proper enclosures is a must.KDM marine instrument enclosures are made of the most reliable materials to help inner devices to operate in the harshest weather conditions, such as storms, thunders, and so on.

# 5. Multiple instrument enclosure

In some cases, the need for simultaneous use of multiple instruments inside one enclosure might arise.

Thus, KDM offers a separate range of multiple instrument enclosures that can group and conveniently store various instruments and electronic devices.

To do so, our specialists utilize DIN rails, special cable holders, and other tools that help to properly use and maintain multiple instruments.

- Instrument panel enclosure

Instrument panel enclosures are cabinets that are used to store various electronic instruments and components.

In general, they are designed to be lightweight and accompanied by desktop or handheld instruments.

Instrument panel enclosures are often found in applications where there is a need for machines to be monitored or controlled manually.

Modern instrument panel enclosures utilize touchscreens, but you can also find equipment that uses push buttons and analog instruments.

# 7. Outdoor instrument enclosure

When it comes to outdoor use of instruments, it is vital to use specially designed enclosures made of certain materials.

To figure out what kind of design solutions you may need, it is important to understand what kind of environment they’ll be working in.

What is more important, KDM specialists have to figure out what are the main hazards that might affect the operation of instruments.

To fulfill each type of need, our company is offering a wide array of IP and NEMA enclosures that can withstand practically any kind of environmental hazards and influences.

# 8. FLP Instrument enclosure

FLP is an abbreviation for “flameproof”.

As it comes from the name, the flameproof enclosure can withstand direct exposure of fire.

To do so, the precise choice of materials is needed, including high-grade stainless steel.

These cabinets are designed to withstand an internal explosion from gases, vapors, specks of dust and fibers to maintain a safe surrounding atmosphere.

# 9. Handheld instrument enclosure

The manufacture of advanced and ergonomic handheld enclosures has been the major focus of KDM specialists for many years.

Modern KDM handheld instrument enclosures have an aesthetic and reliable design and are very comfortable to hold, therefore guaranteeing safe and fatigue-free operation.

In this case, additional options include battery compartments for N, AAA, AA, C, and 9 V type cells, mounting means for PCBs, display modules, PCMCIA cards and connectors, recessed areas for protecting membrane keyboards and product labels, plus molding in reinforced, impact-resistant materials for industrial use.

# 10. Stevenson instrument enclosure

Stevenson enclosure (or Stevenson screen) is a special type of instrument cabinet that is used as a part of a standard weather station.

It holds instruments that may include thermometers, a hygrometer, a psychrometer, a dew fell, a barometer, and a thermograph.

Stevenson enclosure protects the temperature sensors from being influenced by direct or reflected sunlight.

These cabinets are always painted white to better reflect the sun’s rays.

The louvered sides allow outside air to flow around the thermometers.

# 11. Desktop instrument enclosure

In most cases, desktop enclosures are designed for indoor use.

Desktop instruments are typically stored inside plastic enclosures with an ergonomic sloped front.

This technique allows displays and controls to be easily read or used while sitting at a desk.

Our plastic enclosures under this section provide practicality and user-friendly shapes for those exact applications.

Flanged options are available for comms type, surface mounted electronics.

# 12. Medical instrument enclosure

Needless to say that medical electronics and instruments require a special regime of containment.

Medical devices are used intensively, day after day, week in week out, year after year with no let-up.

In each country, the better part of hospitals doesn’t have the resources to continuously buy electronics they will use once in a while.

So this equipment must be able to withstand a punishing daily regime to be handled by lots of different healthcare professionals.

Thus, medical instrument enclosures have to be tough, high-quality, and with a whole host of specialized design features.

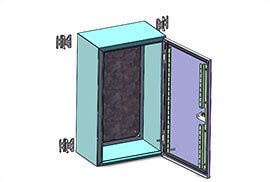

# 13. Wall-mounted instrument enclosure

Wall mounting mechanism helps to save a lot of space inside the facility.

Also, when you mount electronic devices and other instruments on the wall, it helps to create the distance between them and the resource of danger (such as water, dusty surface, etc.)

At KDM, we can offer various mounting options, including wall mounting, pole mounting, DIN rail mounting, and so on.

# 14. Custom instrument enclosure

KDM wide array of instrument enclosures can satisfy practically all kinds of imaginable needs.

However, some applications might be so special that they require the most unique approach.

Thus, we are glad to offer a separate range of specials that can be requested in addition to the standard order: multiple installations, different box designs, customer specified tube diameters, exotic materials, customized heaters, temperature controllers, tube bundles, and much more.

For any of the above-mentioned options please contact our customer’s service.

What Is A Remote Instrument Enclosure?

Remote instrument enclosures (RIE) are self-contained rooms for housing instruments, analyzers, drives, and DCS (distributed control systems).

These constructions are needed to control other industrial equipment automatically, in cases when such events as an industrial explosion, ballistic impact, or natural disaster might happen.

The aforesaid hazards do not just put your personnel at risk, but also your critical equipment and operational ability as well.

To ensure that your facility remains functional at those times, you can effectively protect personnel and equipment in remote instrument enclosures.

Subjected to the highest industry tests and surpassing government and industry safety standards, KDM enclosures are designed to protect operator control rooms, satellite field operator stations, emissions control and monitoring, electrical switchgear, motor control centers, UPS, electrical control rooms and so on.

If you want to learn more about the network connection of remote instrument enclosures, please visit the following page.

How The Instruments Are Mounted Inside The Instrument Enclosure?

When we are talking about panels, switch systems, and other equipment that consists of multiple electrical devices (like fuses, transmitters, and so on), it is better to use DIN rail mounting.

First of all, it helps to properly group and organize inner devices, so you can operate and maintain them freely.

Secondly, the use of DIN rails helps to ensure that your equipment would not change its placement while you move it or while it is jiggled (like in the case of maritime transport).

Also, KDM instrument enclosures can be equipped with special holders, devices sell and other types of adapters that help to effectively store wires, cables, and other needed tools.

What Materials Are Used When Making Instrument Enclosures?

KDM can offer instrument enclosures made of the following materials.

# 1. Stainless steel 304

Stainless steel 304 is low carbon austenitic steel.

The 304 stainless steel is acid-resistant and can withstand short-term temperature rises of up to 900 degrees Celsius.

This type is the main grade in the stainless steel family and contains a minimum of 18% chromium and 8% of nickel.

Such an amount of chromium content provides the formation of an oxide layer on the surface, which makes the steel resistant to various chemicals.

Also, this ratio of the elements in the composition of the alloy allows it to exhibit antiferromagnetic properties.

# 2. Stainless steel 316

This grade of stainless steel sometimes referred to as A4 stainless steel or marine grade stainless steel, is the second most common austenitic stainless steel after 304 types.

It contains alloys of iron, chromium (between 16-18%), nickel (10-12%), and molybdenum (2-3%), with small (<1%) quantities of silicon, phosphorus, and sulfur.

The addition of molybdenum provides greater corrosion resistance than 304, concerning the localized corrosive attack by chlorides and to general corrosion by reducing acids, such as sulfuric acid.

When cold worked, 316 can produce high yield and tensile strengths.

# 3. Carbon steel

High-grade carbon steel is a steel with a carbon content of more than 0.6% (up to 2%).

With the rise of carbon percentage in the mass, steel can become harder and stronger through heat treatment.

Regardless of the heat treatment, higher carbon content reduces weldability.

# 4. FRP

Fiber-reinforced plastic is a high-strength, linearly elastic material used to reinforce concrete structures.

It is an alternative to steel reinforcement elements.

What Kind Of Extra Accessories Can I Order With Instrument Enclosure?

To make our range of enclosures as complete as possible, KDM is able to offer a wide range of accessories to assist with your temperature maintenance, ventilation, and mounting requirements.

The exact parts of an instrument enclosure vary depending on the application.

First of all, we can offer various heating systems for your exact case.

KDM combines a comprehensive range and styles of heating system products with extensive expertise to provide a heating system solution for all potential applications.

For applications that require complete frost protection or temperature maintenance inside the enclosure a special heater might be needed.

Such heaters can take the form of compact aluminum finned units or, where space allows, stainless steel panel heaters.

By selecting the appropriate fixed setpoint thermostat the desired internal enclosure temperature can be achieved and effectively maintained.

Let’s have a look at some accessories that KDM gladly offers to its customers.

# 1. Finned space heaters

Finned heaters are small and neat devices that can be installed in different positions inside the instrument enclosure.

You can decide on the exact position where such heaters would be situated.

Due to their compact design, they do not require a lot of space, thus, you can save some money and order a tiny enclosure that will operate in a proper temperature regime.

The KDM range of finned heaters are available in many power outputs and can accept

110V-240VAC/DC input Voltage.

# 2. Panel heaters

Panel heaters are typically made of high-grade stainless steel and are used in cases where aluminum is not allowed.

Due to the massive size of such devices, panel heaters have to be mounted onto the rear wall of the instrument enclosure.

Please, keep this consideration in mind because you can afford the use of the rear wall not in all applications.

As well as for finned space heaters, the KDM assortment of panel heaters is available in many power regimes and can accept 110V-240VAC/DC input Voltage.

# 3. Steam heaters

A separate stainless steel steam block that mounts directly onto the manifold is used to provide steam heating.

Several ports with tube fittings provide the connection to the steam line.

# 4. Direct contact block heaters

Aluminum or stainless steel block heaters can be mounted directly onto the manifold to provide efficient conduction heating, with a self-limiting output characteristic.

The block heater is supplied with a cable length of 1m as a standard, but other lengths are available as well.

Please, specify what kind of cable do you need beforehand.

# 5. Steam coil

KDM can provide a copper or stainless steel steam coil that routes around the instrument enclosure.

Such a technique helps to provide frost protection and internal temperature maintenance.

Note: To select the most appropriate heating system, the following information might be required:

- Area of operation: hazardous or safe environment (if we are talking about the case of the hazardous environment, please specify certification and temperature class required, e.g. Atex/T3).

- The minimum ambient temperature at the location.

- What kind of resources do you have, electrical or steam?

- What kind of service is required: protection from excessive ice and frost or temperature maintenance?

- If you need heaters for the needed temperature maintenance, please specify the temperature you wish to see.

- Preferred type of heater (space heater or block heater).

Let’s mention that heaters are not the only items that are available for customization of KDM instrument enclosures.

For example, handheld enclosures may have slide-on covers or a separate compartment for an LCD screen.

Also, the vast majority of KDM instrument enclosures may have:

- vents;

- handles;

- locking mechanisms;

- membrane keyboards;

- DIN rail mounting with the ability to slide into different positions;

- wall or pipe stand mounting brackets;

- internal mounting brackets;

- grommets;

- cable glands;

- bulkhead compression fittings.

Other options incorporate neoprene seals or watertight gaskets, transparent lids or covers, recessed areas for labels or keypads, cylinder catches, lock covers, thermometers, drains, air dyers, and special coatings to shield the contents from static electricity or EMI/RFI (electromagnetic and radio frequency interference).

Please, contact us to require more information about extra accessories for your instrument enclosures.

How Does Instrument Enclosure Work?

An instrument enclosure refers to a safety box installed to enclose sensitive electronic instruments.

Against accidental contact, mechanical abuse, dirt, extreme temperatures, and adverse weather effects.

In addition, the instrument enclosure is equipped which comes up with proper insulation basically with these two primary accessories, generally:

- A thermostat

- And space heater

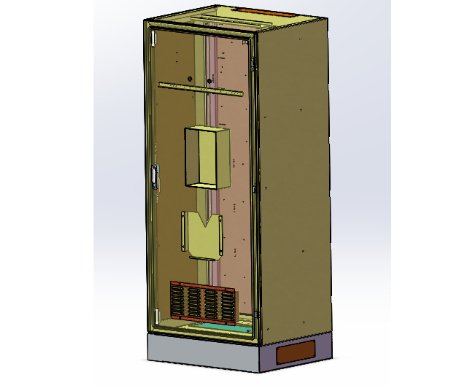

Figure-1 Instrument Enclosure

What are the Features of Instrument Enclosure?

Some critical features of instruments enclosure are the following:

- Heavy-duty resistance

- Successfully endures in any temperature range and harsh weather conditions.

- Simple for assembly

- Provides efficient access

- Easy to machine

- It comes with an attractive aesthetic, structural design

Figure-2 Instrument Enclosure

What are the General Applications of an Instrument Enclosure?

Medical and wellness devices, test and measurement equipment, controllers, and monitoring systems are examples of a typical application.

A wide range of instrument enclosures ideally suited in a particular field, especially in:

- Communication

- Medical

- Automotive

- Agricultural industries

- Technological fields

- Scientific engineering

However, these enclosure types are visibility flooded in different areas such as public and private buildings, residential places, street corners, parks, etc.

What Electronic Instruments Does an Instrument Enclosure Use to Protect?

Instrument enclosure is generally used in protecting all the vital accessories and components, including:

- Desktops

- Portables

- Rack-mounted electronic equipment

- Wellness and medical instruments

- Controllers and monitoring system

- Displays

- Connectors

- Switches

- Measurement equipment

- Transmitters

- Adapters

- Temperature controls

- Watt-meters

- Voltmeters

- Ammeters

What are the Basic Parts of Instrument Enclosure?

The instrument enclosure is composed of essential parts, namely:

- Window

- Two rear panels

- Baseplate

- Mounting bracket

- Insulation adapter

- Process pipe

- Vent pipe

- Clasp

- Mounting hub

- Cable guard

- Access plugs

What are the Materials Use that Instrument Enclosure Made Of?

The instrument enclosure is possibly formulated out of using these different types of industrial materials, including:

- Steel.

Provides high malleability and strength.

- Stainless steel.

Lightweight materials that are perfect for high corrosive environments and places.

- Aluminum.

A material that offers high conductivity and good resistance against oxidation.

- Acrylonitrile Butadiene Styrene (ABS).

An inexpensive and rigid polymer material that has excellent endurance from creep and chemicals.

- Fiberglass.

A sturdy reinforced polymer that has good resistance to over-temperature.

- Polycarbonate.

Excellent resistance to chemical corrosion and provides good strength impact.

- Polystyrene.

Easily constructed material that features adequate dimension stability and hardness.

What Surface Finishing is Used for Instrument Enclosure?

Instrument enclosure used different surface finishing types such as the:

- Smooth brushed finish

- Epoxy painted

- Electropolished

- Powder coating

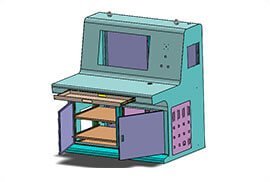

Figure-3 Instrument Enclosure

What is the Specification that Needs to Consider in Instrument Enclosure Selection?

Below are the primary specifications that need consideration in selecting the right instrument enclosure:

Shapes and Measurement

An instrument enclosure typically comes with assorted shapes and measurements.

Its shapes can be readout style, slanted, t-shape, and rectangular, while the sizes may depend on the specified applications.

Material Types

The longevity and durability of an instrument enclosure primarily hang on the material composition. However, the material used is categorized as either metal or polymer.

1. Metal Materials. This classification of materials exerts excellent heat and electric conductivity.

The following list is the most well-known metal materials used for constructing instrument enclosure:

- Steel

- Stainless steel

- Aluminum

2. Polymer Materials. It is a non-metal and inexpensive material with superior properties.

Below are some polymers materials that are also used in constructing instrument enclosure:

- Acrylonitrile Butadiene Styrene

- Fiberglass

- Polycarbonate

- Polystyrene

Quality Protection and Rating System.

Considering the quality protection and rating system is necessary to ensure an instrumental enclosure’s overall performance, safety, and credibility.

-

NEMA Ratings.

This rating indicates that the instrumental enclosure protects the user and the enclosure itself against incidental actions, both hazardous and non-hazardous surroundings.

-

IP Ratings.

It indicates the high degree of instrument enclosure protection from moisture and foreign objects.

What is the Instrument Enclosure Advantage?

The instrument enclosure is highly advantageous to the following:

- It is easy, safe, and straightforward to handle both light-duty to heavy-duty electronic protection and applications.

- Gives 360° easy access to all instrument system components and devices

- Utilizes less amount of operating cost and air consumption.

- It tightly encloses the analytical electronic instruments at the time of operations.

- Safe for all users and service crew

Figure-4 Instrument Enclosure

What is the Standard Measurement of Instrument Enclosure?

The instrument enclosure has different lengths, widths, inches, or depths. It can also be small to extra-large measurements.

Besides, the most significant factor in determining the proper instrument enclosure is the size.

By choosing the instrument’s actual uses, measuring all the instrumental components and devices.

What are the Different Types of Instrument Enclosure?

At below, there’s are some different types of instrument enclosure like:

- Free Standing Instrument Enclosure

- Floor Mount Instrument Enclosure

- Wall Mount Instrument Enclosure

- Stainless Steel Instrument Enclosure