When you are dealing with electrical connections such as switches and fixtures, you need to safeguard from any form of tampering. That is why you need to house them in a junction box to prevent unwanted hazards.

What Is a Junction Box

We can describe a junction box as a form of casing that contains connections for electrical wirings. You will find such enclosures made from either PVC plastic or metal.

Electrical wirings pass through a junction box which acts as a split connection host to your distribution network. You can have an easy access to your electrical connections through the junction box if want to carry out maintenance or alterations.

Features of a Junction Box

There are some certain traits you can only find in junction boxes. Let us have a look at some of these unique identifier features of the junction box.

- It is a plastic or metallic enclosure

- It can house several wire connectors

- They have entry and exit points where the connecting wires enter or exit it

- Some have cable glands at the entry and exit points instead of just holes

- They come in different dimensions and sizes depending on their area of application

Working Of a Junction Box

You should not be surprised that the working of a junction box is a very straightforward affair. You only need to take a single power source, pass it through into the box, and split the power to serve more electrical components.

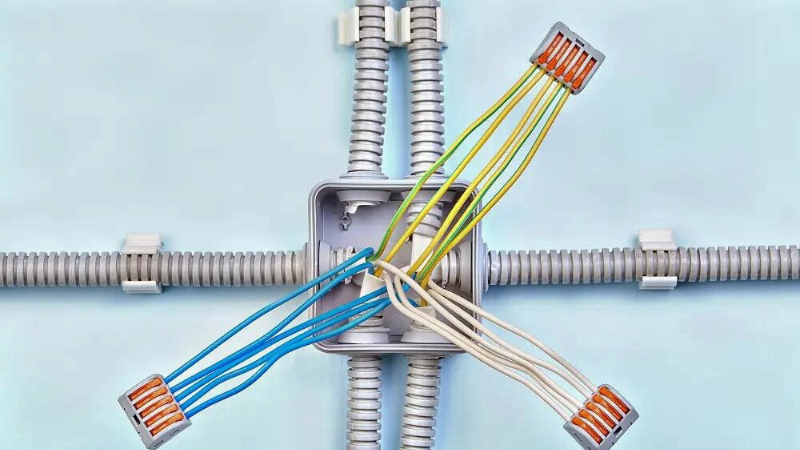

However, you cannot just carry out this operation randomly. You have to carefully select the wires, and connect them appropriately after splitting ensuring that you observe the color coding.

For your connections to work efficiently, you have to fasten your stripped and connected wires using wire nuts. After you have confirmed all connections are okay with no naked wires, you can power your electrical connection, and your junction box will work.

Benefits of A Junction Box

It may look like just a simple basic component but you can gain a lot from it. Let us have a brief overview of some of the benefits you can get from using a junction box:

· Safety

We know that the junction box houses your electrical connections in a confined environment. This minimizes any physical contact you may have with such connections therefore guaranteeing your safety.

If you make any more split connections or even alterations to your electrical system, the joints are protected from extreme environmental conditions. This reduces the risk of accidental fires or water damaging the connections.

· Grounding

You will not require any form of grounding when using plastic junction boxes because of the obvious, they are non-conductors. Additionally, they eliminate the electrocution risk you may face in case they contain a naked live wire.

· Cheap

If you opt for a plastic junction box, then it will cost you much less compared to other junction boxes. It a favorite for many contractors since they won’t need any form of clamps to mount them anywhere.

· Flexibility

With junction boxes, you can easily make alterations to your existing electrical connections or modify them. They offer you a convenient location from where you can carry out such activities.

Various Types Of Junction Boxes

When we look at it from a broad perspective, we can classify junction boxes based on the material they are made from. This means that you may get either a metallic junction box or one made of hard plastic such as PVC.

For the metal junction boxes, you will find materials such as steel or aluminum which are commonly used to make them. Such metal boxes are usually robust and durable enough to serve you for a very long time.

Whatever the material, we still classify the junction box further either based on their design or functionality. Let us have a look at some of the common types you will find and the purpose they will serve you:

· Round Pan Junction Box

This junction box is designed to be used for simple ceiling fixtures and basic wall lighting. They are usually very shallow and small in size and diameter with a depth of between 0.5” to 0.75”.

Since their size is limited, you can only make a total of three wire connections on them. Any more connections you make beyond this will overstuff it and increase the risk of electrical fire.

· Standard Regular Junction Box

You can find them as either plastic or metallic with measurements ranging between 2” to 3” in size with a depth of between 1.5” to 3.5”. You can use these “one-gang” boxes for single-wire connections or as receptacles for normal power outlets.

We have standard regular boxes having a detachable side meaning they allow ‘ganging’. This means you can easily detach the side and join it with other boxes to form a larger junction box of two or more of them.

· Standard Square Junction Box

This box is mostly used in applications where you have to lay many conductors going in more than two directions. The fact that they are square gives them additional space at the corners that enables you to place many connectors inside.

Their dimensions are a depth of about 1.25” to 2.125” with a 4” length on all sides. They are either plastic or metallic and you can use them for light switches or any lighting fixtures at home.

· Standard Round/Standard Octagon Junction Box

If you want to place light fixtures on your wall or ceiling, then these two are your best bet for junction boxes. They are usually larger than the round pan box meaning you can have more wirings compared to it.

Their dimensions and diameters vary according to their shape. However, you will find a depth of between 1.5” to 3” for both of them.

· Ceiling Fan Junction Box

Just as the name suggests, you can use these boxes as an electrical fitting for your ceiling fans. You will normally find them as round-shaped or octagon although other shapes and designs do exist.

Since they carry a heavy load that is rotating, you have to ensure that you tightly fasten it to your ceiling for stability. This is because besides acting as a junction box, it is also a support for your suspended fan.

· 2/3/4 Gang Junction Boxes

These devices can support either two, three, or four outlet devices based on the number of gangs on them. Though mostly applied for industrial uses, you will find them either in square or rectangular form.

· Outdoor Junction Boxes

These junction boxes are usually waterproof and heavily sealed to protect your connections from external effects. You normally mount them outside your house or premise on walls, or decks where your application is.

You have to check whether the rate for your junction box can withstand your wet location for your application. The common materials for such boxes are high-impact PVC or steel and aluminum metal that will serve you for a long.

Installing Junction Boxes

We are going to look at how you can install your junction step by step. For starters, you will have to turn off your power supply for obvious reasons.

Let us analyze the step-by-step procedure for installing your junction box:

- You can use either a voltmeter or a tester to confirm that no current is flowing in your connecting wires.

- We have two application areas where you have to install your junction box, either inside your house or premises or on its exterior. You have to use nails to fasten your interior box or screws for external junction boxes.

If your junction box is metallic, then you will need to reinforce it using cable clamps placed from the box’s exterior.

- Next, gently pull your cables through the openings of your junction box to the inside. Make some half-inch markings on the point your connectors have just passed the clamp.

- You can now remove the cables from your junction box and make a splice on each that is 6” from your first mark. Return the cables inside your junction box and if they are metallic, use the clamps to reinforce them.

You will not be required to do the same with plastic junction boxes. This is because they have self-tightening clamps.

- Check the sizes of your wire so that you use the appropriate stripper size for them. Before cutting, you can place on the end of the wire next to the stripper to ascertain this.

- Proceed to strip about an inch of the connecting wires that you want to use in your junction box. Be careful when stripping so as not to damage the wires while doing so.

- Join all the wires using color coding. The best way to start this is with the ground wires if you are dealing with a metallic junction box.

- You can reinforce the grounding by using a pigtail for the metal boxes. While joining the wires, you can reinforce and fasten them much tighter by using pliers.

- After the grounding wires, connect the neutral wires then finish with the love connectors. After that, give each connected wire a slight tag to ensure that they are tightly connected.

- Seal any naked wires using insulating tape and neatly fold your connections to fit inside your junction box.

- Replace the junction box cover and fasten it with screws in place. Switch on your power and your junction box is good to go.

Junction Box Safety Ratings

Just like any other electrical device, you will find in the market. Junction boxes also have to attain a certain level of safety. Such measures are there to ensure your safety and the general industry safety standard practices.

Here are the three main junction box ratings and what they stand for:

· NEMA Ratings

According to NEMA (National Electrical Manufacturers Association) ratings, junction boxes should protect your connections against dust and liquid. They rate the junction boxes from 1 to 13, the order being non-progressive.

Each number rating represents that junction box’s resistance to certain environmental conditions. You will also find some letter ratings after some of these numbers that show enhanced resistance.

Let us look at some of these ratings and their meanings:

- NEMA Type 1: they offer protection to your connections against human contact and objects. You can use them in applications having water or oily and dusty environments.

- NEMA Type 2: you can use them for indoor applications and protect your connections from corrosion and dirt

- NEMA Type 3: you can use the junction boxes for both indoor and outdoor applications. They can protect your connection from rain and dust in addition to damage during snow

- NEMA Type 3R: junction boxes mostly for outdoor and protected against rainfall and snow. If you use them for indoor applications, your connections are protected from dripping water.

- NEMA Type 3S: designed exclusively for outdoor use with the protection offered against rain, ice from snow, or dust that is blown by wind.

- NEMA Type 4: you can use them in applications having a lot of water splashing such as pressurized water streams.

- NEMA Type 4X: you will find these boxes made of high-grade plastics and quality stainless steel. You can use them in adverse conditions such as applications having corrosive chemicals such as caustic cleaners.

- NEMA Type 6P: you can use them for both indoor and outdoor applications in applications that involve submerging in water. You should note that they only work well in shallow submersions.

- NEMA Type 12: regularly used in manufacturing to protect connected devices against water, oil or dust contamination. They protect devices such as electronic drive systems when stationed outdoors.

- NEMA Type 13: you can use these junction boxes for your indoor applications. They protect your connection against oil and dust, dripping water, and coolants that don’t corrode.

· IP Ratings

The International/Ingress Protection ratings also describe certain protection levels for junction boxes. You will spot them in your junction boxes as IP prefixes followed by two numbers with an optional letter at the end.

As we have said, the first digit after the IP prefix tells you the protection your junction box offers against invasion from foreign objects. The digits are as follows:

- 2: offers protection against solid objects that are less than 12.5mm in size

- 5: offers protection to your connections against mild ingression of dust

- 6: your junction box is dustproof

The second digit after the IP prefix shows you the level of safeguard it gives your connections against water. These digits are:

- 0: your junction box has no safeguard against water

- 2: protects your connections against vertical water contacting it at an angle of 15°

- 4: can withstand any jet of water contacting it from any direction

- 5: this junction box protects your connections from water jets having low-pressure

- 6: it can protect your connections against any high-pressure water jets

UL Ratings

The Underwriter Laboratories (UL) ratings have their ratings for junction boxes. However, these safety and quality standards are specific to junction boxes that cater to high-voltage equipment.

They are rated numerically from 1 to 13 with some ratings having a letter after the number implying an enhanced protection. You should note that the ratings are non-progressive meaning higher ratings don’t necessarily translate to superior protection.

Components of A Junction Box

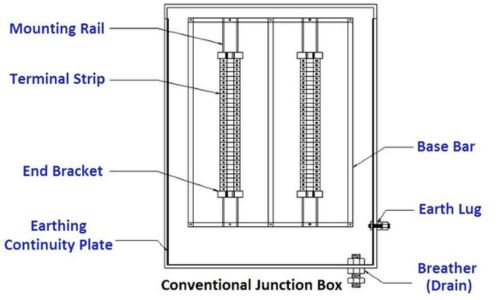

A junction box is a very simple structure with basic components. It is a plastic or metallic enclosure having either wire connectors, terminal blocks, or is just a space depending on your application.

Junction boxes have entry and exit points for your wire connections that are usually just holes made on the sides. Depending on your application, you will find others with glands at these points to fasten your connecting wires.

The glands also act as protection from the entry of foreign objects and extreme environmental hazards. Other boxes have the connector part of a mating cable placed instead of glands to simplify your connection.

Applications of Junction Boxes

There are very many applications you can find for junction boxes ranging from home to commercial use. Your application area will dictate the type of junction box you will use.

Let us list down some of these common applications:

· Domestic Use

Your home can greatly benefit from junction boxes in very many aspects such as regular electricity receptacles and lighting fixtures. You can also use fan junction boxes to mount fans on your ceiling and others to cater to your outdoor electric equipment.

· Warehouses

Warehouses have environmentally friendly surroundings in as much as they consume a lot of electricity in their operations. Due to the nature of the operation of warehouses, you have to install impact-resistant junction boxes.

They are normally large with enough space to cater for further connections and alterations when needed. They are mostly located outdoors though you can find some stationed within the premises.

· Medical Facilities

Electrical connections in medical facilities are very delicate since they sustain life-saving machines and critical medical procedures. The junction boxes used are rigid, placed indoors, and tamper-proof but easily accessible.

· Offices and Shops

These two are the least of places that require junction boxes besides lighting fixtures and fittings. However, they are there and are bigger than the one we use for residential applications though mostly placed indoors.

Junction Box Material

The main materials used to make junction boxes are metal and plastic. As for the metallic ones, you can find them in many variants such as galvanized steel, steel or aluminum.

These junction boxes are durable and can serve your application for quite a long time. They do an excellent job when it comes to protecting your connections from physical damage.

As for the plastic junction boxes, they are made from very high-strength PVC or even ABS plastic. Due to their high strength, they can last longer than ordinary plastic in your application.

They have a very light build and benefit you impressively even in corrosive application environments. However, you will need to use them mostly for indoor applications since they don’t react well with direct sunlight.

Junction Box Vs Terminal Box

Although they may appear similar in structure, these two serve different purposes. As we have seen, we use a junction box to house our wire electrical connections for easy access during repairs and alterations.

On the other hand, terminal boxes are enclosures we use to house terminal blocks that join different conducting wires. These terminal blocks are insulated and ensure that all your wire connections are properly terminated.

Junction Box Wiring Connection

When using junction boxes, we are simply taking a single source wire connection and splitting the power to serve other applications. The three wires you can use for this are the live wire (red/brown), the neutral wire (blue) and the earth wire (green/yellow).

Your connection to the junction box should run from the main electrical panel. These connections are usually the regular connecting wires used for regular domestic wiring units.

These wires have a non-metallic sheath that you can strip when connecting to other wires. After splicing these main wires, they are connected to other wires that distribute the supply to the different electronic devices.

For your junction box to function efficiently, you have to ensure the uniformity of the diameter gauge of your wires. This will ensure that your connections do not undergo any energy losses due to that disparity.

Safety Precautions During Junction Box Installation

When installing your junction box, there are some safety precautions you should adhere to. Some of these include:

- If you are mounting your junction box on any surface, then ensure you use the mounting holes that are there specifically for the box.

- For every connecting wire that is involved in your connections inside the junction box, splicing must be ¾” from its end.

- Never leave any naked wire inside your junction box. Twist unused wires of the same color together and tie them using an insulating tape.

- Ensure that all your connections are safely tucked inside you junction box before sealing it

- When making connections on your junction box, ensure that the mains supply of your connectors is turned off. This is to avoid any risk of electrocution

- You should ensure that anu metallic junction box you install should have a functioning ground wire attached to it.

- Make sure that the location of your junction box is in an area where you can easily access it in case of anything.

Choosing The Right Junction Box

When sourcing for the most appropriate junction box for your application, there are some certain aspects you need to look into. We can analyze some of them to give you a better understanding of how to go about it.

· Number Of Terminals

The number of connections your application requires will determine the type of junction box you will go for. You will find most junction boxes have 3 to 6 terminals therefore confirm the exact with your application

· Material

Some of your applications will function well with a plastic junction while others are better off with a metallic one. Check all the environmental conditions surrounding your application area before choosing the best material for your junction box.

· Junction Box Rating

Different junction boxes have different safety ratings described by their manufacturers. You should go for a junction box that has a rating similar to the requirements of your application.

· Wiring Method

The type of wiring method in your application greatly determines what type of junction box you will use. If your application has metal-sheathed cables, then you need to go for metallic junction boxes while conduit ones are good for conduit fittings.

Conclusion

Junction boxes are very important in your electrical connections for many reasons. Safety is very important and the junction box ensures you get just that in whatever application your electrical connection is.

With a proper understanding of how they are rated and how they work, you can settle for the best junction box. They also ensure that your electrical systems are working in the most reliable environment.

More Resources:

Electrical Box – Source: Science Direct

Terminal Box Vs. Junction Electrical Box – Source: KDMFAB

Junction Electrical Box– Source: KDMSTEEL

Junction Electrical Box Vs Electrical Box – Source: KDMFAB

Metal Junction Box Enclosure – Source: KDMFAB

Junction Box– Source: WIKIPEDIA