Pull boxes and junction boxes are very important in the organization and effective functioning of an electrical system. However, what is a pull box and junction box, what are their differences and how can you choose the best for you. These are the questions that this article seeks to answer.

What is a Pull Box?

Pull boxes are forms of enclosures that allow you to organize and pull wires in an electrical system. It serves as a form of pit stop for any wire traveling very long and complex routes. When you’re running wires of this type, pulling it could become an issue. This is because the wire could damage or strain. This is why a pull box is important because it is the access point that allows you to pull the wire gradually, thereby preventing stress from getting to the system.

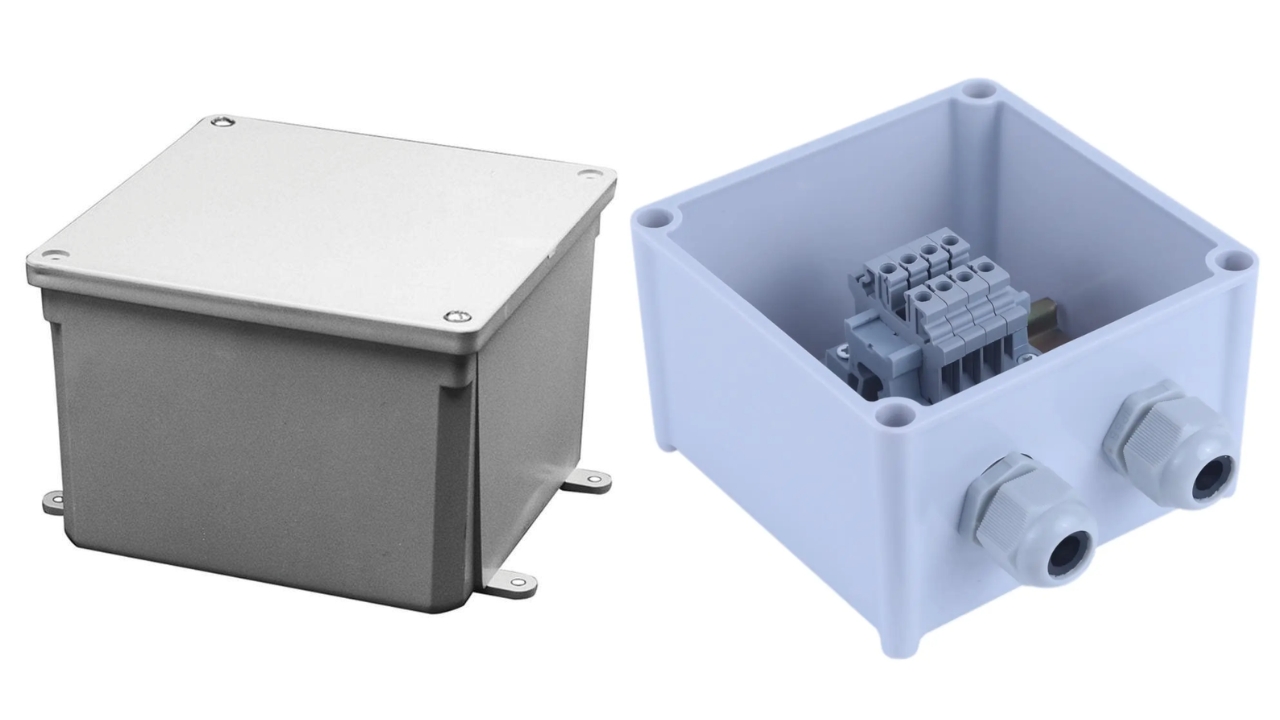

What is a Junction Box?

Junction boxes offer protection to your wire connections. This ensures safety and better organization for these wires. Also, with your junction box, you are giving your wires from damages or from hazards. With a junction box, you will find it easy to find solutions to all your wiring problems.

Pull Box vs Junction Box: What are the Main Differences?

Here we will be explaining the main differences between pull box vs junction box, considering areas such as functions, design and size, materials used, how it complies with the NEC, cost, and more. Let’s begin.

Functions

The main difference between pull box vs junction box is in their functions. With a pull box, you can have access to your electrical conductors and wires. Its main function is to ensure that you pull, reroute, and organize your wires easily. They are useful for large-scale systems like those seen in commercial buildings and industrial settings.

Whenever the conduit runs have many bends, it could be difficult for you to pull the wires without causing damage to them. With a pull box, you can reduce strain which will allow you to pull the wire in areas you can manage.

For example, you are running an electrical system that has some bends and spans about 210 feet. With a pull box, you will be able to pull your wires with ease, thereby reducing the time it takes to install and preventing any damage.

For junction box, it helps in housing your electrical connections. Thus allows it to organize and offer protection for joining the wires. Also, they help in protecting your wires from moisture, or possible damage, thereby preventing electrical fires or other hazards. In contrast to the pull boxes, they are smaller in size, thereby making them suitable for small projects and residential use.

You can use junction boxes in homes for connecting wires for switches, outlets, as well as light fixtures.

Design and Size

The design and sizes of a pull box vs junction box serves their unique purposes. Generally, pull boxes are larger in size due to their ability to hold long sections of a cable or wire. They usually come with enough space to allow easy access to the wires, ensure easy adjusting as well as rerouting. Also, a pull box includes removable covers that allow electricians to access the inner wiring easily.

Pull boxes have shapes that are suitable for your conduit system, which are usually square or rectangular. Larger installations ensure that pull boxes can house many conduits.

For junction boxes, they are usually compact and have a smaller size. Their design can protect your wires and reduce whatever space they are occupying. The junction boxes usually feature knockouts as well as a cover, which you can fasten safely. Its compactness allows you to install them easily in the ceiling, and in other small spaces.

As pull boxes manage your long wirings, junction boxes will help you to organize and protect the wire connections.

NEC Guidelines

The installation of junction boxes and pull boxes requires carefulness. Therefore, you need to adhere to the requirements of the National Electrical Code, when installing these boxes.

NEC Requirements for Installing Pull Boxes

- Proper label: Ensure you label your pull box properly. In this regard, the label must reveal its function or use. This is very important when you are using it in complex wiring systems.

- Good spacing: According to the NEC, adequate spacing is important when installing your pull box. During installation you will need to pull and bend wires. Therefore, you need enough room to do this without damaging your wires.

- Accessibility: Install your pull box in areas where you can easily inspect or fix them when necessary. Avoid installing behind walls or areas that are difficult for you to have access.

NEC Specifications for Junction Boxes

- Ensure the size of your box can take the wire capacity. This means your box should have enough room to accommodate all the wires.

- Your junction box must be in an accessible area. This will help you carry out inspection easily.

- All connections in your junction box must be safe and secure. During installation, ensure you put all splices in an enclosure to prevent short circuits.

- If you plan to install your junction box outside, seal it up to prevent it from harsh elements like rain. This will also prevent dirt from entering your box.

To ensure safety and prevent damages, it is important you follow these guidelines. Also, these guidelines will help you increase the life span of your electrical system.

Material Choice

Pull and Junction boxes are available in different material types. The operational environment is a major factor that influences the type of material used for these boxes.

Types of materials used for pull boxes include:

- Plastic (PVC): Plastic is a good material option for pull boxes due to its properties. You can use plastic pull boxes for both indoor and outdoor settings. This is because it is resistant to corrosion.

- Galvanized steel: You can use galvanized steel pull box in heavy-duty applications. In such applications, you should use galvanized steel due to its ability to withstand wear and impact.

- Stainless steel: Stainless steel is a corrosion-resistant material that can survive in a high-moisture environment. You can use stainless steel pull box in outdoor locations.

Common Materials for Junction box include the following:

- Metal: Metal junction boxes have a high heat resistance. You can use them in settings that have exposure to very high temperatures.

- Plastic: Plastic is another suitable material for junction boxes. You can use them for outdoor and indoor applications. The benefits of using plastic junction boxes include durability and corrosion-resistant properties.

Cost

If you are working with a budget, it is important you know the cost difference between these two boxes.

Pull boxes are bigger and heavier. Therefore, they require durable materials which are usually more expensive. Due to the materials used for pull boxes, you can use them in high-performance applications. Galvanized metal pull boxes designed for industrial purposes are more expensive than the regular ones.

On the other hand, junction boxes have a small size and simple design. You can find them in residential settings since they are less expensive. They are the right option to opt for if you are considering cost.

Although junction boxes are more affordable, you should choose the best material that suits your environment. So not compromise cost for value. Make sure you weigh the benefits of the junction box you are choosing.

Environments

A pull box can survive even in different environments. This is because different materials are useful when manufacturing them. These include metals, which makes them durable and strong and plastic which makes them lightweight, great for outdoor use and resistant to corrosion. You can use a pull box in huge projects like factories, wiring streetlights, industrial plants, etc.

Also, you can manufacture junction boxes from different materials to work in several environments. These include metal, which is durable and strong and great for indoor use, and plastic which offer lightweight properties, ensuring that these boxes are suitable for use outdoors as well as in wet environments.

These junction boxes could come in a rectangular shape or a square shape. You can remove their covers to help offer protection to the wires. You can find junction boxes virtually everywhere such as walls, basements, behind outlets, ceiling installations, etc

Advantages of Pull Boxes

You will gain many benefits from using pull boxes, especially in industrial applications.

- Works with complex wires: Pull boxes can work very well with complex wires. For instance, in industrial settings where complex and large wiring systems are common, pull boxes are a good choice.

- Less wire strain: You can put too much strain on your wires due to multiple bends. Pull boxes can help you reduce damage that may come from pulling.

- Easy maintenance: You don’t need to spend too much on maintenance and repairs since pull boxes help you access your wires without stress.

Advantages of Junction boxes

- Prevent damages: Junction boxes allow you to put splices in enclosure, thereby protecting your connections from damages.

- Great design: Junction boxes are small in size and have great design. You can use them in applications where there aren’t enough spaces.

- Minimizes risk: Junction boxes help you minimize the risk of fires or short circuits. This is because they protect your wiring.

Pull Box vs Junction Box: How to Choose the Best Box

Here is a guide to choosing the best box for you

- Ask yourself what you need. Do you want an access or a connection point

- Check factors such as heat, moisture, as well as the impact

- Make sure that the box you are choosing can handle all your conduits and wires

- Work with the NEC’s requirements; this ensures compliance

- Pick a design and location which allows you to have easy access during repairs

When Should You Use the Boxes?

There are some situations you must consider before choosing between pull box vs junction box.

Pull boxes are useful when:

- You want to access your wires easily for repairs and possible upgrades in the near future

- You have tight areas and many bends in your wiring system

- You wish to run conduit covering long areas and distances like two buildings

Junction Boxes are useful when:

- There’s a need to connect many wires like when you are installing light outlets

- You work in a small commercial space and a residential area where it is important to use compact solutions

- The installations requires the creation of branches in your wiring systems

Conclusion

Pull boxes are different from junction boxes, but they are very important for your electrical systems. With a pull box, you can achieve easy maintenance and long wirings, while with a junction box, you are protecting your splices to organize your connections and protect them. Understanding the differences between pull box vs junction box, you will be able to make better decisions, achieve safety, and achieve better efficiency for your projects.