Custom Circuit Breaker Enclosure Manufacturer

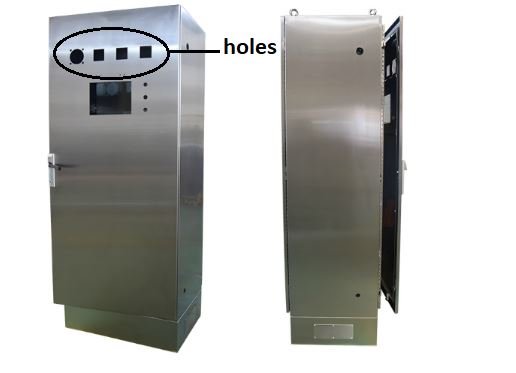

KDM circuit breaker enclosure ideal for a variety of environments including general-purpose, rainproof surface mounting, water and dustproof, dustproof surface mounting, and hazardous location. This product provides enhanced safety by enabling reduced levels of incident arc flash energy when placed in the maintenance mode.

- KDM circuit breakers enclosure will protect your circuit breakers.

- Whether your breaker is located outdoors or indoors, our circuit breakers enclosure effectively protects your devices from dust, corrosion, and other outside elements that can cause damage.

Different Types of Circuit Breaker Enclosure Rocket Your Business

KDM offer various surface mount option for mounting single and double pole circuit breakers. This enclosure will accept any of the breakers styles shown below in the related products section. It can be used for single or double pole breakers. Also, accommodates optional LEDs and square format labels, at the same time wire glands and fasteners are included. These enclosures provide the flexibility to meet more applications.

At KDM, we have an extensive variety of enclosures across several NEMA ratings including, type 1, type 3R, type 4/4X, type 12 circuit breaker enclosure which provide an ideal solution to protect your circuit breakers from dust, rain, corrosive materials other outside elements that can cause damage. KDM circuit breaker enclosure provides a cost-effective solution for utility-scale systems and offers current protection for individual circuits.

The Feature of Circuit Breaker Enclosure

KDM circuit breaker enclosure consists of a thermal-magnetic molded case circuit breaker mounted in a UL listed circuit breaker enclosure with a through-the-door handle for operation. The handle mechanism does not allow the cover to be opened without the breaker being in the OFF position. Thus, the circuit breaker enclosure offered by us has all the advantages and accessories of a circuit breaker packaged in an enclosure you need to complete the job.

KDM Offers You An Excellent Choice of Circuit Breaker Enclosure

KDM provides a circuit breaker enclosure designed for overload and short circuits protection as well as control of lighting and power circuits. They are explosion-proof, dust-ignition-proof, and watertight models that can be used in areas where hazardous materials are handled or stored. Our circuit breaker enclosure comes with an integrated fan, vent, and thermostat options.

For circuit breaker enclosure custom solutions, you can count on us. We provide a wide range of enclosures in many sizes and finishes that can be fully customizable. Our highly trained professionals and designing team will help you to fulfill the specific demanding needs of your project.

For over 10 years, had been serving the electrical construction materials needs. Our vast experience in manufacturing allows us to offer the best of our products, which is intended for your specific uses. All our circuit breaker enclosures will protect the personnel from hazardous parts inside the enclosure.

- Manufacturing Capacity

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experience workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

Expert assembling team, consistent assembly quality on every KDM enclosure

Circuit Breaker Enclosure: The Ultimate FAQ Guide

In today’s guide, I have compiled all questions and answers about the circuit breaker enclosure.

It aims to educate and make you an expert in the circuit breaker enclosure industry.

So, if you’re looking forward to learn or import circuit breaker enclosure from China, this is a-must-read guide for you.

Let’s have a look:

- What is a Circuit Breaker Enclosure?

- What is the use of a Circuit Breaker Enclosure?

- Why use Circuit Breaker Electrical Enclosure?

- What is a Circuit Breaker?

- What is the Function of a Circuit Breaker?

- Does Circuit Breaker Enclosure Require Cooling?

- When should you Heat Circuit Breaker Enclosure?

- Is there a difference between Industrial and Residential Circuit Breaker Enclosures?

- What is IP Rating for Circuit Breaker Electrical Enclosure?

- What are NEMA Ratings for Circuit Breaker Enclosure?

- What is the Significance of NEMA ratings?

- How does Type 3R Circuit Breaker Enclosure compare to Type 1 Circuit Breaker Enclosure?

- Is there difference between NEMA Type 4 and Type 12 Circuit Breaker Electrical Enclosure?

- What are the components for Circuit Breaker Electrical Enclosure?

- Where can you use Circuit Breaker Enclosure?

- What are the Characteristics of Weatherproof Circuit Breaker Enclosure?

- What is Single Pole Circuit Breaker Enclosure?

- How do you Maintain Circuit Breaker Electrical Enclosure?

- How much does Circuit Breaker Enclosure Cost?

- How can you Cool Circuit Breaker Electrical Enclosure?

- How do you ventilate the enclosure system?

- Which Safety Features does Circuit Breaker Electrical Enclosure come with from the manufacturer?

- How can you Test Quality of Circuit Breaker Enclosures?

- What is Circuit Breaker Enclosure Quality Standards?

- Does Circuit Breaker Electrical Enclosure require Ventilation?

- How do you choose Circuit Breaker Enclosure Windows?

- Do Circuit Breaker Enclosure come Pre-assembled or you Assemble On-site?

- What is the Best Material for Circuit Breaker Enclosure?

- How do you specify an Enclosure for Circuit Breaker?

- What do you need for Cable Management in Circuit Breaker Enclosure?

- Can you get Custom Circuit Breaker Enclosure?

- What makes Circuit Breaker Enclosure different from other Electrical Cabinets?

- Which Mounting options do Circuit Breaker Electrical Enclosures come from the Manufacturer?

- Which Surface Finish options are available for Circuit Breaker Enclosure?

- Do Circuit Breaker Electrical Enclosures have Specific Voltage and Current Ratings?

- What is UL Listed Circuit Breaker Electrical Enclosure?

- Is Circuit Breaker Enclosure the same as Junction Box?

What is a Circuit Breaker Enclosure?

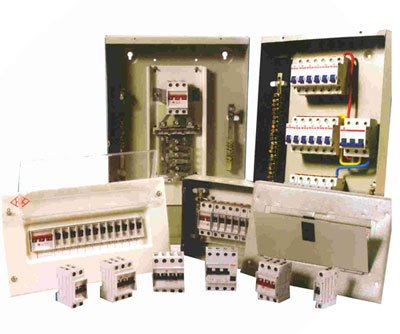

A Circuit Breaker Enclosure is a dissemination board designed to shield the circuit breakers, switches, and motor circuits.

Basically, it has accessories such as boards, rails, cooing system, ventilation accessories and heating systems in a cabinet like structure.

Normally, the design of enclosure cabinet is such that it houses circuit breakers and other electrical components.

Circuit breaker electrical enclosure

What is the use of a Circuit Breaker Enclosure?

Circuit breaker enclosure protects the circuit breaker from the adverse conditions of the surroundings and the equipment operators.

It also ensure only authorized personnel have access to the circuit breaker system.

Additionally, it makes managing circuit breakers for different electrical and electronics systems easier.

This makes monitoring and improving the entire electrical infrastructure easier.

Why use Circuit Breaker Electrical Enclosure?

To safeguard the operators and the electrical system from the dangers of high voltages.

What is a Circuit Breaker?

It is a mechanically controlled electrical gadget designed to offer protection to the electrical circuit from surplus current or risks of short-circuiting.

Circuit breaker is a popular component in electrical network system.

Circuit breaker

What is the Function of a Circuit Breaker?

A circuit breaker protects an electrical route from harm triggered by dissipated current from short circuit or an overload.

Besides, its primary role is to intersperse the current flow after the detection of an electrical fault.

Besides, it isolates the electrical system from the risks of arc flash, thereby safeguarding the operators in the power supply source.

For instance, the SF6 circuit breaker does the role of preventing arc flash.

Similarly, a protective relay is a significant component in a circuit breaker.

The role of the relay is to detect unusual circumstances and send back the sensed tripping signals to the circuit breaker.

Thus, the protective relay makes a circuit breaker more effective.

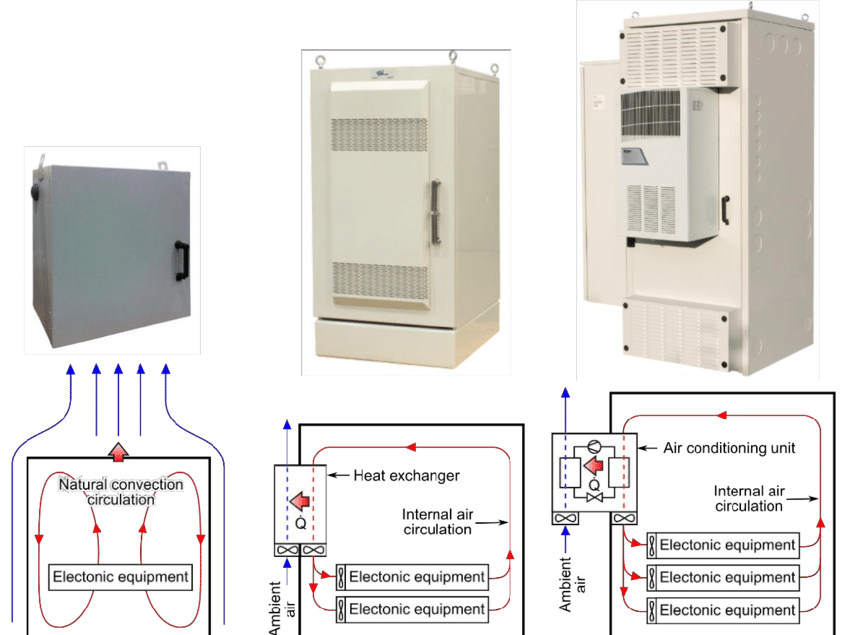

Does Circuit Breaker Enclosure Require Cooling?

Yes.

There is a need for cooling in the circuit breaker enclosure.

The current rating of the interrupter is established on the evaluation of the ambient temperature for the surrounding air.

The air of higher temperatures can cause an impact on the tripping features of the interrupter.

Besides, the standard interrupters must not get hotter than 50 degrees Celsius or 90 degrees Fahrenheit above the ambient temperature.

Therefore, the enclosure requires the necessary airflow organization that enables it to pass the requirements of the thermal test.

It should not exceed the specified standards regarding temperature limits.

Cooling electrical enclosure

When should you Heat Circuit Breaker Enclosure?

It depends on the internal temperature of the electrical enclosure system.

The temperature variation in the circuit breaker enclosure may affect the operations of the internal components.

The phenomena that might affect the temperature in the circuit breaker enclosures are the exchange and circulation of both external and internal air.

Besides, it is vital to keep the internal temperature of the cabinet at the optimum level.

When the temperature inside the enclosure is below the specified standards, heating becomes pertinent.

Moreover, the required temperature is 50 degrees Celsius/ 90 degrees Fahrenheit.

When the temperature of the circuit breaker enclosure falls below this limit, then cooling is significant.

Furthermore, heating is applicable for upholding safety and effective functioning.

When the temperature is low in the system, it can affect the operation of the electrical components inside.

Importance of heating electrical enclosure:

- Aids in the removal of moisture and avoiding condensation: the presence of moisture in the enclosure can cause corrosion. When the internal humidity approaches 65%, then issues related to humidity and corrosion exceed.

- Assists in the prevention of the interrupter failure and downtime: Keeping the steady temperature in the enclosure enhances the lifespan of the breaker hence, preventing the collapse of the electrical gadget.

- Helps in maintaining the equipment to work at ideal levels: keeping the circuit breaker enclosure at optimum temperature range maintains the electrical gadget operating effectively.

- Aid in preventing corrosion: moisture is dangerous when it interacts with dust, it can result in equipment failure when the significant parts get corroded with dirt.

Some of the circuit breaker enclosure heaters are Fans, explosion-proof heaters, and PTC heaters.

Is there a difference between Industrial and Residential Circuit Breaker Enclosures?

Yes.

The industrial and residential circuit breaker enclosures differ in features that brings the variations in place of application, depending on the requirements.

Features of residential circuit breaker enclosure

- Current ratings are 100 to 225A maximum

- It has short circuit ratings of 22k RMS.

- Perfect for 100A to 225A suburban uses with Sq. D Load centres, circuit breaker enclosures, and so on.

- It offers elasticity to encounter more uses with a single interrupter format, that also streamlines inventory stocking.

Features of Industrial circuit breaker enclosure

- Appropriate for application as a service entrance device.

- The short circuit current of the cabinet rating is equivalent to the breaker rating, at the source voltage noticeable on the circuit interrupter installed except otherwise eminent in the digest.

- It has a power rating of 125- 400A, 250V dc/ 600V ac.

- Appropriate in risky places as specified by Article 500 of NEMA.

What is IP Rating for Circuit Breaker Electrical Enclosure?

The IP rating refers to the degree of protection an electrical cabinet provides to the circuit breaker and the related components.

IP rating refers to International Protection Code

.

When it comes to classifying circuit breaker enclosure cabinet based on IP rating, you will see two numbers.

That, you will see IP 55

or IP 56

circuit breaker enclosure.

Normally, the first number refers to the ability of the electrical enclosure to provide protection against particles or objects.

These may include dust, fingers or any equipment.

On the other hand, the second digit refers to the degree of protection from liquids.

This may include dripping water, splashing water, etc.

Therefore, the degree of protection will depend on the two numbers.

Below is a detailed explanation of all IP rating standards:

IP Protection

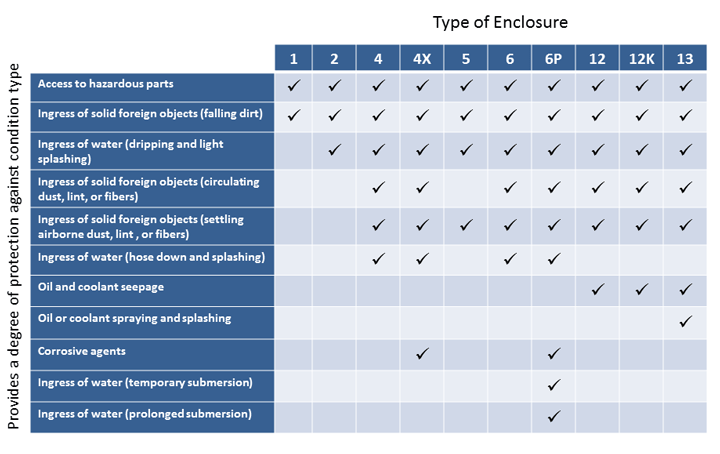

What are NEMA Ratings for Circuit Breaker Enclosure?

NEMA is a short form of the National Electrical Manufacturers Association (NEMA) which promotes standardization of electrical enclosure cabinets.

NEMA Rating is a voluntary standard that states different degrees of protection for circuit breaker enclosures.

Depending on the performance criteria, you can classify circuit breaker enclosure as NEMA Type 1, NEMA Type 2, etc.

Below are examples of NEMA Rating and different protection standards:

NEMA Rating

What is the Significance of NEMA ratings?

- The NEMA ratings assist you in confirming that the electrical cabinet has proper compatibility, protection, and operational standards.

- It permits you to evaluate the kind of enclosure is appropriate for the environment in which you want to do the installation.

- It offers you guidelines, helping in understanding all about the circuit breaker enclosure safety and operation.

How does Type 3R Circuit Breaker Enclosure compare to Type 1 Circuit Breaker Enclosure?

Type 3R– Cabinets designed for either outdoor or indoor applications to offer a degree of safety to operators against access to dangerous parts. Besides, it gives protection to the internal devices from the intrusion of falling dirt.

Again, to offer a degree of safety regarding detrimental effects on the device due to the invasion of water.

Nevertheless, to prevent damages that might be caused by the exterior formation of ice on the cabinet.

Type 1– Enclosures designed for indoor applications to offer a degree of safety to operators from access to risky parts.

Moreover, it gives protection to the internal devices from the intrusion of falling dirt.

Is there a difference between NEMA Type 4 and Type 12 Circuit Breaker Electrical Enclosure?

Type 4/ 4X– Circuit breaker enclosure is designed for either outdoor or indoor applications to offer a degree of safety to operators against access to dangerous parts.

Besides, it gives protection to the internal devices from the intrusion of windblown dust & falling dirt.

Again, to offer a standard safety regarding detrimental effects on the device due to the invasion of splashing, and hose-directed water.

Nevertheless, to prevent damages that might be caused by the exterior formation of ice on the cabinet.

Type 4X cabinets offer an extra level of safety against corrosion.

Type 12/ 12K (Type 12 has no knockouts while Type 12K has knockouts).

They are enclosures designed for indoor applications to offer an average safety to operators against access to dangerous parts.

Besides, it gives protection to the internal devices from the intrusion of solid external objects like circulating dust and lint.

Again, to offer standard security regarding harmful effects on the device due to the interference of light splashing and dripping water.

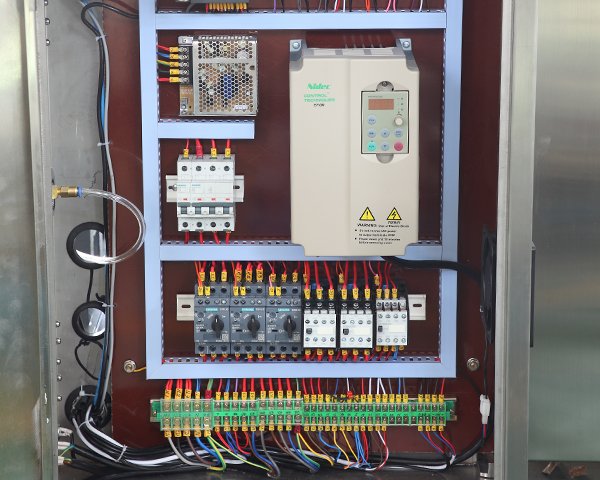

What are the components for Circuit Breaker Electrical Enclosure?

The cabinet of the circuit breaker should have the following components for efficiency:

Circuit breaker electrical enclosure

Air Conditioners– Designed to keep a specified temperature inside the cabinet by applying a closed-loop approach.

Also, ensures that the environment is free from contaminants and safeguards electrical constituents from overheating.

Moreover, air conditioners work better than filter fans in cooling the enclosure and its components.

Heat Exchangers– They ensure that the internal environment has optimum temperature and maintains it.

Heaters– It is a very vital component that assists in heating the enclosure when the internal temperature falls below the optimal level. The specified optimum temperature is 90 degrees Fahrenheit.

Thermostats– The device is significant in keeping the working temperature of the circuit breaker enclosure within the required range.

Its primary function is to control the flow of coolants from the cabinet to the outside environment.

Thermistors are crucial in sensing temperature variations in the electrical enclosure.

Then sends a resistance signal back to the alternating current regulation module that makes involuntary adjustments to maintain the cabinet at the appropriate temperature.

Mechanical Hygrostats– Designed to regulate the relative internal humidity of the cabinet.

Besides, it is risky for the equipment to experience internal condensation.

It can cause a fault in the device—the hygrostat assists in turning the heater for the maintenance of the humidity at the optimal level.

Fans– They are ideal for cooling the cabinet and maintaining the internal temperatures at an optimal level. Besides, the forced ventilation fans enhance Ventilation in the enclosure.

Window Kits and Locking Mechanism– They have doors, latches, and locks.

The principal purpose of those features is to protect the internal components.

The locks keep the equipment inaccessible to outsiders, except the authorized operators.

Latches offer support to the window kits in a position to ensure safety.

The doors of the window kits provide accessibility to the inside of the electrical enclosure.

Where can you use Circuit Breaker Enclosure?

It relies on the location of the application, either indoor or outdoor.

Circuit breaker enclosure is applicable in both indoor and outdoor power sources, which can be vital in either industrial or residential areas.

The enclosure equipment is useful in such places to offer higher standards of safety against access to risky parts.

What are the Characteristics of Weatherproof Circuit Breaker Enclosure?

Features are:

- The enclosure was built of an extraordinary excellent electro-galvanized sheet made from steel.

- It is accessible for outdoor and indoor applications.

- It has a padlocking facility, offering exceptional security to the internal components.

- It is a spacious enclosure that provides ease of wiring.

- It has a very high resistance to extreme weather conditions, protecting the internal components from exposure to adverse situations.

- It has a provision of earth and neutral terminals.

- It has a mounting bracket prepared from an electroplated sheet made of steel.

- Its knockouts for entering cables are provided on every side of an indoor enclosure, and for the outdoor cabinets, the knockouts are at the bottom sides.

- For outdoor enclosures, they have CNC machines created gaskets to warrant better fastening.

What is Single Pole Circuit Breaker Enclosure?

A Single-pole breaker enclosure is a kind of cabinet explicitly designed for enclosing a single-pole circuit interrupter.

The single-pole interrupter provides a range of 15 to 20 amps, 120V, and has a single hot wire and a separate neutral wire.

The equipment is useful in curling irons or hair dryers, outdoor lighting systems, power tools, fans, air compressors, and many more.

How do you Maintain Circuit Breaker Electrical Enclosure?

The following maintenance practices are pertinent:

Circuit breaker electrical enclosure

Inspect/ Examine the Electrical Enclosure

You should always conduct a visual examination- how frequently relies on the harshness of the environment of the enclosure.

In case of the situation of extreme weather exposure, do assessments frequently.

You can as well inspect less regularly when the climate is milder.

While, in case of other elements effects like regular temperature variations, vibrations, or large equipment operating nearby, then you must inspect more often.

Even insignificant problems, if left uninspected, can result in greater issues in the future.

Be on the watch out for:

- Loosened clamps, screws, and nails. You should ensure that they are tight on the spot maintain the enclosure ceiled fitted to safeguard against the elements like snow and rain.

- Holes & dents. There are gears you can buy that will restore small holes and dents.

Still, in case a cut appears severe, the enclosure might require a more comprehensive assessment to ensure that the reliability of the inclusion is always complete, and parts are not broken as well.

- Parts damaged down. Kinds of Stuff such as conduit linking flexing and tension exposure can tear down rubber gears and seals.

Condensation from cold may be able to result in corrosion, sidle flashovers, and currents.

Extreme heat can temper and make the circuit interrupters to a fault and demonstrate strain, and things simply wear out.

Always Conduct Cleaning

- Every electrical component exposed to the external elements requires regular cleaning. It is even critical in harsh environments in which the quantity of dirt and chemical constituents in the air can build up rapidly.

The situation can alter the thermal attributes of an electrical enclosure, which can destroy temperature dissipations.

Replace Damaged Parts and Components

- Finally, every part of the enclosure wears down.

When you realize a disintegrating seal or screw goes missing, execute their replacement immediately as it might be the encouragement of water to leak onto the electrical components.

General Care of Circuit Breaker Enclosure

- Always ensure that everybody is closing and opening the cabinet closures the cabinet once done.

The practice will assist in lengthening the lifespan of the enclosure and the internal electrical components considerably.

Electrical precautionary preservation and analysis are some of the utmost significant roles to be performed to sustain the integrity and dependability of electrical delivery systems.

This will also guarantee the safety of personnel and equipment.

If you correctly preserve your enclosure, it will assure you several periods of good use.

If, conversely, something does fail or is not operating appropriately, always invite/ involve an expert to assist with maintenance services of the electrical components.

How much does Circuit Breaker Enclosure Cost?

There are many factors that determine the cost of circuit breaker electrical enclosure.

These factors may include:

- Size of an electrical enclosure

- Degree of protection the circuit breaker enclosure offers – these include, NEMA Rating and IP Rating

- A number of accessories – circuit breaker enclosure with air conditioner system will be more expensive than one without.

Can you Insulate Circuit Breaker Enclosures?

It is vital to insulate the circuit breaker electrical enclosure because the procedure assists in enhancing the safety of the internal components, and the operating personnel.

Besides, this will increase the lifespan of the equipment.

The insulation materials should be able to tolerate varied environmental conditions. Namely:

- Extreme heat or coldness.

- Dangerous weather conditions. For instance, torrential rains, storms, hail, and snow.

The insulating material should not be plastic or any synthetic stuff since it cannot resist fire or extreme heat.

Besides, the covering should be able to protect the internal components from external interferences.

The material that is mostly used for insulation purposes is metal, either made of steel or Aluminum.

insulated electrical enclosure

How can you Cool Circuit Breaker Electrical Enclosure?

Since higher temperature rises, so place your exhaust fans as raised as viable in your enclosure to ensure that your system is efficient.

Maintain your inlet fan lowly built in the cabinet to take in the coldest air conceivable.

You should place your temperature sensor at a point where you anticipate might be exposed to the highest temperature.

So, your fans can rotate in the event of abnormal conditions regarding temperature rise.

To maintain cooling the circuit breaker cabinet, you must ensure that the electrical enclosure has proper Ventilation.

How do you ventilate the enclosure system?

In a perfect setup, a fan must be located close to the roofing of the enclosure designed to take out air.

Another fan is positioned in proximity of the bottom to let in air.

Sometimes, the internal components, such as heaters in the enclosure, might make the air temperature to rise.

Electrical enclosure with vents

Methods to maintain cooling in the enclosure

a) Active cooling

It entails two approaches:

Forced Convection:

You can make the blowers and fans do the cooling when the passive convection is not probable.

It is established on the law of convection where the fans exchange the air faster all over the enclosure.

Hence, enhancing the cooling effect.

While applying filters to safeguard the cabinet from deterioration, they do not provide any safety against extreme disparities in humidity.

· Air Conditioning

If convection fails to cool the enclosure, you can attempt to apply closed-loop cooling.

The heat exchangers can cool the air efficiently in colder surroundings where humidity can affect the design.

Also, air conditioners are the best cooling, electrical enclosures situated in hot environments.

b) Passive Cooling

It encompasses convection.

The design of enclosures should include vents, are deliberately located to enable the hot air to discharge and replace with cooler air.

It is because heat transfer involves movement from a material of higher temperature to another with a lower temperature.

This approach works for maintaining the electrical enclosure’s cooling, although its viability depends on the position of the cabinet.

Therefore, passive cooling is only applicable where the external air remains steady at a lower temperature than the internal air.

Similarly, you might need to deploy air filters on the vents to avoid dirt or dust from intruding the enclosure.

Which Safety Features does Circuit Breaker Electrical Enclosure come with from the manufacturer?

i. Continuous hinge

Their benefits are;

- They are intense all over their whole lengths since every knuckle bears a load.

- They strengthen the electrical cabinet- hinge enhances product firmness by offering support to the whole application period.

- Simpler and more precise to align than an increased number of butt hinges.

- They are more appealing and consistent in appearance.

- They are even in necessary action, offering ideal axial rotation.

- They are economical, long-lasting through numerous swing rotations.

- They are versatile- accessible in numerous variations and are simply adapted to fit individual applications.

- They have an even firmness of the gasket down the length and height of the cabinet.

- They are rated for protection.

ii. Concealed hinge

Significance

- Aesthetics- totally hidden from view when the door latches.

- Its installation is simple- hidden door hinges usually are much simpler to install than an old door hinge. Nearly all of them are created to slide on and off, permitting you to fix them devoid of any tools.

- The typically hidden hinge comprises a 2-inch kept at a point by an e-clip enabling easy exclusion of the door for distinct alterations or wiring.

- It is rated for security.

iii. Clamp Cover

Its Significance

- It makes operation easy, basically closes clamps for fastened sealing.

- Superior sealing- offers tougher fasten, unlike hinge style.

- The whole door is detachable by unlocking the clamps enabling a simple entrance to electrical cabinet contents.

- It is rated for security.

iv. Clamp-style latch

Significance

- It is dependable- it has a verified performance.

- It is durable.

- It is versatile.

- It is easy to install.

- It is rated for security purposes.

v. A system of 3-point turn latch

Significant

- It enhances security- three-point latching allows the bottom and top of the gate to be instantaneously protected in a supplement to the point at which the handle turns.

It is achievable by drawing two long steel rods alongside the latch adjacent to the door, which outspreads vertically downwards and upwards.

It efficiently stops the bottom and top of the door and considerably enhances the security of the door-locking associated with a door with just a single-point closing.

- Aesthetics- more appealingly satisfying than a clamp

- It enhances ease of contact with the electrical cabinet contents.

- It is versatile- it has both clockwise and anti-clockwise turning options of the handle.

- Its installation is easy – there is no requirement for special tools.

- Non-compulsory key locking handles are accessible.

- It is rated for protection reasons.

vi. Quarter turn latch

Its Significance:

- Simple operation- disengages and engages with a smooth quarter turn. By the knob, only moving a quarter turn, accessibly withdraws the slide for ease of opening.

- It enhances the simplicity of access to electronic cabinet contents.

- It is more appealingly satisfying than a clamp.

- It is versatile- tools or keys that rotate the latch are accessible in numerous varied shapes.

- It provides safety- accessibility of varied shapes held lessen undesired interference and enhancing protection.

- It is easy to install- there is no requirement for special tools.

- It is rated for security.

All the mentioned features made are following the NEMA quality standards and UL rated.

How can you Test the Quality of Circuit Breaker Enclosures?

Circuit breaker enclosure

According to IEC 61439- 1, the properties of the insulating material must certify the following tests:

- Resistance to ordinary temperature.

- It has a high resistance to great fire and heat.

- Thermal stability, for isolating cabinet.

- Endurance to ultraviolet (UV) radiation, for an external application.

The mentioned tests certify that the material acts as a satisfactory isolator even when exposed to extreme environmental conditions.

As a result, that toughness illustrates that the cabinet and the entire system will operate as premeditated for years in the future.

Regarding endurance to average temperature, IEC 61439 10.2.3.2 states that the initial manufacturer will certify that the isolating materials do not alter mechanical routine at temperatures of 125o C.

That is, for parts that carry current and 70o C for other things.

According to the guidelines, it assurances operation during the life of the cabinet.

Due to the temperature needs, plastic cannot be part of the insulation of accommodating electrical equipment.

Usually, plastic insulation might seem less costly, but it is not resistant to heat and fire.

Besides, the flammability tolerance and heat endurance properties ensure safety during the usual process and when issues occur due to inside electrical faults.

The execution of the tests, like for usual heat, UV tolerance, and variable temperature, assure the quality of the isolating material.

In return, they affirm cabinet specifiers that the quality standards of the ultimate structure will not be compromised for a while by the environmental conditions.

So, the excellent circuit breaker and its cabinet remain at a position comparable to the time when the equipment was new.

What are Circuit Breaker Enclosure Quality Standards?

Quality standards for circuit breaker enclosure that are commonly used include RoHS, CE, UL Listing, IP Rating, and NEMA classification.

Of course, these may also vary depending on the geographical location.

Does Circuit Breaker Electrical Enclosure require Ventilation?

Yes.

Enclosure ventilation is the practice of executing a mechanism that allows free airflow inside the electrical cabinet.

Indeed, the circuit breaker enclosure may heat up, causing temperature to rise above the optimum.

Therefore, a free flow of air is significant in improving the cooling system.

Also, through the cabinet ventilation system, dirt, vapor, and fumes get out of the electrical enclosure.

All the processes ensure protection and an extended service lifetime of the electrical components.

The electrical enclosure ventilation systems might encompass vents, louver windows, fan systems, and small openings.

Louvre for electrical enclosure

How do you choose Circuit Breaker Enclosure Windows?

You should consider whether the circuit breaker enclosure windows meet the following standards:

· Material used to Construct the Enclosure Window

Currently, tech revolutions in material science expand the available choices when choosing an enclosure window material.

The material should be corrosion resistant and be able to endure harsh weather conditions.

For instance, acrylic is the most economical material for making enclosure windows.

It is lightweight, flexible, and has an exceptional endurance than glass.

Regarding its softness, blemishes and scratches can be eliminated by buffing.

Acrylic has optical precision, filters UV light, and develops fissures instead of shattering.

It is also excellent for resisting harsh weather.

· Durability and Custom Design Accessibility

You should as well ensure that the enclosure window is long-lasting.

The durability of equipment assists in saving, no recurrent replacement after a short period of operation.

Likewise, design availability is crucial in terms of management.

In case of need for replacement, the required window kit should be easy to find.

· You should Consider the Nature of the Enclosure Window

The enclosure window can be either hinged or fixed.

For instance, a fixed enclosure window is permanently locked on the circuit breaker enclosure.

Its fixing is done using adhesives or screws.

Hence, you cannot access the inside, but just to view the interior of the electrical cabinet.

On the other hand, a hinged enclosure window enables you to access the internal components since you can either open or close the window.

Moreover, a hinged enclosure window might have a latching and locking mechanism.

· Enclosure Windows should be NEMA/ IEC Certified

The NEMA/ IEC rankings define the overall electrical cabinet specifications for varied types of surroundings.

For instance, the NEMA enclosure has a given rating (let’s assume that it is type 10/ type 1), it resolves that every accessory such as doors, enclosure cooling system, or windows must be present.

Some of the enclosure windows that you can choose from are:

a. Stainless steel enclosure window- designed with shatter and scratch-resistant. It offers total mounting hardware.

b. Non-metallic enclosure window- constructed from a blend of polycarbonate and enhanced with UV, absorption, collision, saturation, water exposure endurance.

c. Hinged enclosure window- it has latching, height options, individual widths availability.

Is Circuit Breaker Electrical Enclosure Lockable?

Yes.

It is crucial to install a lockable electrical enclosure to enhance the security of the internal components.

For instance, in the case of outdoor equipment, safety is highly commendable.

The circuit breaker enclosure can have an enclosure system with doors, latches, and locks.

The latches have the role of holding the door of the cabinet at a position while the locks do the work of securing the electrical enclosure.

Do Circuit Breaker Enclosure come Pre-assembled or do you Assemble On-site?

The circuit breaker enclosure can be pre-assembled or assembled on-site.

Both options are crucial in varied ways.

For instance, when the electrical enclosure is pre-assembled, it provides a one-supplier solution, also savings on the internal components.

Another benefit is that the in-house team of engineers, tradespersons and technicians instantaneously working on the result at every stage, from design to development, to production, till commission.

Besides, when the electrical enclosure is pre-assembled, it is time-saving to the end-user.

After the delivery of the fully assembled equipment, the electricians only play the role of wiring up the system.

Sometimes, it can be time-consuming to wait for enclosure components from either different suppliers or a single supplier.

They might deliver them in bits, at various times, being built by different subcontractors.

Again, production, operations, and maintenance personnel are saved from the distress and time of getting the electrical cabinet from one location.

On the other hand, when the electrical enclosure is built on-site, it provides enough space for future modification.

Sometimes, the pre-assembled equipment may not have a space for alterations in the future.

Unfortunately, the On-site building may be time-consuming since different suppliers might deliver the enclosure components.

What is the Best Material for Circuit Breaker Enclosure?

The best material for the circuit breaker enclosure is painted-carbon steel.

Painted carbon steel saves on cost, with a moderately robust finish best fitted for indoor uses. Its corrosion resistance is restricted.

Other commonly used materials for electrical enclosures are type 316 stainless steel, type 304, polycarbonate, and fiberglass.

How do you specify an Enclosure for Circuit Breaker?

The circuit breaker enclosure should have the following systems, which are significant for the operation of the internal components:

Figure 12 Circuit breaker electrical enclosure

i. Cooling System

It entails vents, thermistors, fans, air conditioners, and so on.

The vents are small holes that permit a free flow of air inside the circuit breaker enclosure.

They enhance cooling in the electrical cabinet in case of temperature rises above normal.

Thermistors are crucial in sensing temperature variations in the electrical enclosure.

Then sends a resistance signal back to the alternating current regulation module that makes involuntary adjustments to maintain the cabinet at the appropriate temperature.

The gadgets are significant in maintaining the operating temperature of the circuit breaker cabinet within the specified range.

Its principal purpose is to regulate the flow of coolants from the enclosure to the external environment.

Air conditioners- Created to maintain a required internal temperature of the electrical cabinet by applying a closed-loop approach.

Besides, they ensure that the location is free from contaminants and secure the electrical components from overheating.

Moreover, air conditioners work better than filter fans in cooling the enclosure and its components.

Fans- They are essential for cooling the electrical enclosure and maintaining the internal temperatures at an optimal level.

Besides, the forced ventilation fans enhance Ventilation in the cabinet.

ii. Heating system

It encompasses hygrostat, heaters, heat exchangers, and many more.

Mechanical Hygrostats- Created to control the relative humidity in the cabinet. Also, internal condensation is dangerous for the equipment to experience. It can result in a fault in the device—the hygrostat assists in turning the heater to keep internal humidity at the optimal level.

Heaters- It is a vital component that helps in heating the enclosure when the internal temperature drops below the optimum. The stipulated optimum temperature is 50 degrees Celsius.

Heat exchangers- They ensure that the internal environment has optimum temperature and maintains it.

iii. Security system

It comprises window kits that have doors, latches, and locks. The principal purpose of those features is to protect the internal components.

The locks keep the equipment inaccessible to outsiders, except the authorized operators.

Latches offer support to the window kits in a position to ensure safety.

The doors of the window kits provide accessibility to the inside of the electrical enclosure.

What do you need for Cable Management in Circuit Breaker Enclosure?

Cable management in an electrical enclosure refers to the organization of electrical cable in an electrical enclosure or an installation.

It supports and holds cables throughout the installation period and makes successive care of the cabling system simpler.

You need to assess the effect of cabling before contracting, which offers vital benefits ahead of establishing a better-organized cabinet and a tidier plant floor.

Deliberate cable management strategy in the design phase can resolve in a tidier system that lessens cable count and excludes possible errors and stages of malfunction.

Cable management in the electrical enclosure

Can you get Custom Circuit Breaker Enclosure?

Yes.

At KDM Steel, we provide a custom circuit breaker enclosure.

They are highly accepted by the International Electrotechnical Commission, NEMA, and other tech entities concerned with quality standards.

The circuit breaker enclosure has the IP65/ IP66 certification.

In case of need, we can provide it in three days.

Our circuit breaker cabinet will secure your circuit interrupters from various environmental conditions; hence, saving you from faults.

The KDM circuit interrupter cabinet can efficiently secure your gadgets from corrosion, dust, and other external elements that might cause destruction.

It offers safety even if your circuit interrupter is an indoor or outdoor type.

Our circuit breaker cabinet is perfect for various environments, including rainproof surface mounting, general-purpose, dustproof surface mounting, water and dustproof, and hazardous locations.

What makes Circuit Breaker Enclosure different from other Electrical Cabinets?

Circuit breaker enclosure differs from other electrical cabinets regarding the construction and the purpose of its building.

The circuit breaker enclosure cannot be made from plastic since the material will not provide the standard protection. Besides, plastic is not fire and heat-resistant.

The electrical enclosure’s role surpasses other electrical cabinets.

It offers improved protection by allowing decreased levels of event arc flash energy when put in proper care mode, unlike other electrical cabinets.

Which Mounting options do Circuit Breaker Electrical Enclosures come from the Manufacturer?

Mounting is the way a circuit breaker enclosure may be physically reinforced on a given mounting plane.

There are several available mounting options for circuit breaker enclosure, which includes

Wall mount, floor mount, pole mount, and free-standing options.

· Wall Mount Circuit Breaker Enclosure

The wall mount type is a waterproof design for outdoor circuit breakers.

A wall-mount circuit breaker enclosure fixing can either be done sideways or vertically.

Wall mount circuit breaker cabinet is ideal when you have a constrained space use, making a whole size enclosure impractical.

The wall mount elevates the cabinet, delivering valuable floor space.

The advantage of a wall mount electrical enclosure is that it helps in saving space, hence, economical in installation.

Although there are limits for the inside space in the wall-mount enclosure, it may not accommodate every component.

· Floor-mount Circuit Breaker Enclosure

Standard floor mount electrical cabinet

- It should have either single or double doors with a detachable middle post configuration regarding your device mounting requirements.

- It should be an economical and durable continuous hinge offering smooth essential action and optimum axial interchange.

- It should have Counter-clockwise or clockwise rotation and a simple-to-install 3-point latch system offering smooth access.

- It should have a back panel for simple mounting of vulnerable electronic and electrical control contents, constructed for a diverse-sized back panel, or rails for rack mounting.

Besides, the floor-mount circuit breaker enclosure should meet NEMA standards. It should have:

Gland plate, thru-hole, vent, drip shield, window, door stay, coupling, fan cover, roof, sun shield, leg stands, and many more.

It should have eye bolts for lifting.

You should customize the circuit breaker enclosure to your exact specifications with insulation, cutouts, latches, hinges, or locks.

· Free-standing Circuit Breaker Enclosure

Its design is to accommodate a very wide/ large circuit breaker.

It is available in multi-door, double-door, and single-door configurations.

It is NEMA rated, IP 65/ IP 66 or above the grade, and very easy to install and use.

· Pole Mount Circuit Breaker Enclosure

Its design is for external environment applications.

They are accessible in varied sizes while constructed as per the NEMA standards.

Similarly, the pole-mount circuit breaker enclosures meet several IP and NEMA ratings and can suit on pole diameters ranging from 2 inches to 12 inches.

Besides, the pole-mount circuit breaker cabinet is specially designed for withstanding hostile weather conditions, vibrations, vandalism, and even to reduce the harm faced during corrosion.

It is applicable where overhead cabling is frequently used.

The pole-mounted electrical enclosure offers exceptional protection in your circuit breaker for the harshest of environments.

Thus, the pole-mounted electrical enclosure is available with a variety of fixing bracket alternatives for connection to inner support poles, external phone or light posts, or any other rod-like objects.

Pole mounting brackets might be attached to the back wall hardware or welds of the cabinet.

Moreover, the circuit breaker can be mounted in the enclosure with several options, which include snap-in, screw mount, DIN rail, and bushing mount.

Which Surface Finish options are available for Circuit Breaker Enclosure?

Every manufacturer has varied powder coating descriptions standards.

You should ensure that you discuss with your manufacturer about their specifications alternatives before placing an order.

It will significantly help you to obtain an improved understanding of the tint quality your merchandise will receive.

Some of the available surface finish options for the circuit breaker cabinet are class A, B & C finish.

Class A finish

- It involves increased costs.

- It applies to parts where high aesthetics are crucial to the client.

- It has a limited number of allowable defects.

- It has a lengthier inspection time.

Class B finish

- It is of average cost.

- It has few allowable flaws.

- It has an average assessment time.

Class C finish

- It is of lower cost.

- It applies to concealed parts where corrosion safety is vital, but cosmetic flaws are not.

- It has more allowable faults.

- It has a shorter or average examination time.

When selecting paint for finishing your electrical enclosure, you should consider that:

- Lighter colors will dispel the heat and reduce the internal temperature of the circuit breaker enclosure.

Besides, darker colors will hold heat and raise the interior temperature of the cabinet.

In outdoor functions, lighter colors reflect radiation from sun rays and work at lower temperatures.

- For harshly corrosive submissions, an impeding primer with an overcoat of urethane or epoxy is recommendable.

- Also, textured finishes usually are relatively cheaper, simpler to touch up, do not indicate fingerprints as quickly, and deliver an appealing appearance.

Sometimes, a textured paint finish may be difficult to clean up.

- Security matters or commercial specifications are pertinent to consider when choosing a color though some unique colors may add expenses and improve lead times.

Powder Coating Paint Finish

You can validate if the powder coating is of excellent quality by determining the specular reflection of the surface circuit breaker enclosure.

You can conduct the test by applying a gloss meter.

It shines the glow on the Surface at a corrected angle, then determines the quantity of reflected light.

Do Circuit Breaker Electrical Enclosures have Specific Voltage and Current Ratings?

Yes.

For instance, the residential circuit breaker enclosure has a different power rating from that of industrial applications.

The current ratings for a residential circuit breaker enclosure are 100 to 225 Amps.

Maximum, with a short-circuit ratings of 22 k RMS.

The ratings indicate that the residential circuit interrupter enclosure is appropriate for 100 A to 225 A suburban applications.

On the other hand, the industrial circuit breaker enclosure has a power rating of 125- 400A, 250V dc/ 600V ac.

The ratings are as per the NEMA standards, as specified by Article 500.

What is UL Listed Circuit Breaker Electrical Enclosure?

A UL-listed circuit interrupter enclosure is a kind of enclosure whose design is following the Underwriter Laboratories (UL) quality standards.

The UL is an entity that develops safety and quality standards for electrical cabinets, high-voltage device containment, and so on.

UL quality standards are closely related to NEMA standards.

For instance, a 3R/ 4X type of circuit breaker enclosure has a design that obeys the standards of UL and those of NEMA.

Every UL-certified standard electrical enclosure has an array of features and alternatives, enabling you to adapt the cabinet to your exceptional environment and application.

Is Circuit Breaker Enclosure the same as Junction Box?

No.

The primary use of a junction box is to assist in recognizing where the intersections are in a wiring circuit.

Besides, it is useful in keeping rodents away and acts as a backing point for interlocking cable conduits.

You can use a junction box to extend your wiring system.

Besides, you should be cautious and avoid cramming so many wires into the box, it is hazardous and against the National Electrical Code.

Having come to the conclusion of the circuit breaker enclosure FAQ guide, I hope you found it useful.

That is, you got answers to the questions you have been asking.

Still, if you have a personalized question, which I didn’t answer here, feel free to contact the KDMSteel team.

What is the Purpose of Circuit Breaker Enclosure?

A circuit breaker enclosure protects circuit breakers from any outside elements, such as corrosion and dust.

It is effective for indoor or outdoor uses.

Using a circuit breaker enclosure can protect personnel from contacting energized parts.

Additionally, it protects the circuit under short or overloads circuit conditions.

Why I Need Circuit Breaker Enclosure?

A circuit breaker enclosure is necessary to avoid electrified parts access.

It has all openings closed.

What Is A Circuit Breaker Enclosure Application?

A circuit breaker enclosure is applicable for housing molded case switches, motor circuit protectors, and circuit breakers.

It is built to be a reliable and safe switching device for commercial, residential, and industrial premises uses.

What is the Quality Standard of Circuit Breaker Enclosure?

Most of the circuit breaker enclosure offers sealable equipment compliant to NEC 100.

It should comply with the requirements of OSHA like the tag out or lockout.

Additionally, circuit breaker enclosures must exceed the requirements of UL 50 for particular environmental conditions.

And, circuit breaker enclosure also complies with NEC240.30 for physical damage protection.

What is the IP Rating of Circuit Breaker Enclosure?

The circuit breaker enclosure is mostly rated to IP55.

IP55 rated circuit breaker enclosure is protected from harsh weather conditions.

What is the Feature of Circuit Breaker Enclosure?

1. Design

- Aesthetics: The design of the circuit breaker enclosure is modern, elegant, and attractively fits outside or inside your home.

- Color: Available in a fresh color scheme to blend with the color of your wall.

2. Safety

- Protected from Electric Shock: The effective earth continuity protects the operator from possible electric shock when touching enclosures.

- Dead Front Panel: It can eliminate the risk of accident when touching the live parts in the panel during operation.

3. Performance

- Thermal Stability: The circuit breaker enclosure’s thermal stability is ensured and validated via temperature rise test under IEC 61439-3. It can ensure the product’s functionality at steady temperature states.

- Mechanical Impact: Most circuit breaker enclosure is rigorously tested to resist the impact load under the IEC 61439-3 International Standard. It can ensure the strength requirement of the specific application.

- Altitude: Regardless of the installation height and mounting location, the circuit breaker enclosure must be 2000m altitude rated.

4. Reliability

- The Enclosure and Internal Parts are Corrosion Resistance: Through electro-galvanized steel sheets, the corrosion protection of the enclosure is double. The process is utilizing a salt spray test of 1000 hours validation. It could ensure circuit breaker enclosure’s functionality under corrosive and atmospheric conditions.

- Ingress Protection: Circuit breaker enclosure exceeds IP55 ratings. It provides ingress protection against water and solid in outdoor and indoor applications.

5. Installation

- Ample Wiring Space: It can provide abundant space for wiring the outgoing and incoming cables easily.

- Knockouts: These are designed to accommodate multiple-sized glands and conduits of international standards. It has no shard edges and can be easily opened which may damage the conduit and wires.

- Depth Adjustability: The pan assembly depth of the circuit breaker enclosure can be adjustable. It ensures the breakers will not recess in the box. It also banishes a gasp between the breaker and the cover after door installation.

- Cement Guard: It can protect cement deposits when installation occurs. It also keeps a clean box for pan assembly installation.

- Phase Barriers: Circuit breaker enclosure has phase barriers. It is being installed at the main breaker terminals. The purpose of these barriers is to avoid the risk of electrical faults and to increase creepage distances.

6. Environment

7. Testing

What Are the Testing Requirements of Circuit Breaker Enclosure?

Each circuit breaker enclosure must undergo strict quality control under the routine verification listed below:

- Dielectric test

- Insulation resistance test

- Electrical continuity test

- Ingress protection test

- Short circuit tripping test

- Overload tripping test

- Other tests