The NEC, as the minimum safety requirement for electrical installations in the United States, provides comprehensive guidance for all industries. What specific electrical standards does the NEC specify? If you need to install electrical wiring systems in buildings using junction boxes, this article will discuss the NEC requirements you need to follow.

What is the NEC Code?

The National Electrical Code(NEC) is a model regulatory text formulated by a non-governmental organization, which is the minimum safety requirement for guaranteeing personal and property safety. NEC aims to promote the correct electrical wiring and provides a comprehensive guide for electrical installation and equipment. NEC has detailed the safety methods for installing electrical systems. Besides, NEC also provides comprehensive guidance on safety precautions. Installing correctly according to the guidance content can help you prevent fires, clicks and malfunctions.

How NEC is Updated and Maintained

The NEC code forjunction box itself does not have legal effect, but most states in the United States have adopted NEC in legal form as the electrical regulations within their jurisdiction. The rigor of NEC’s writing and its wide application have made it the most internationally influential electrical specification. It has already become the foundation of insurance and justice.

One major aspect of NEC’s authority stems from its advanced technology and security. It is updated and revised every three years and reviewed by an expert panel to make electrical installation safer and more efficient.

NEC Requirements for Junction Boxes and Enclosures

NEC has specific requirements for all aspects of junction boxes to guarantee correct electrical wiring and its safety. The following are some specific requirements of NEC for junction boxes.

NEC 314.28—Junction Box Material

Section 314.28 stipulates the material selection of junction boxes, which are usually made of metal or plastic. You can evaluate yourself based on the installation environment to adopt the appropriate specific junction box.

Material Requirements

The production of junction boxes usually employs non-combustible materials, such as stainless steel and PVC. Of course, when choosing the material for the junction box, you should also take into account various different usage environments.

For instance, if your installation environment is damp, moisture can easily seep into the junction box, posing a threat to electrical safety. Therefore, you need to use a junction box with an appropriate moisture-proof grade.

If you install it in some corrosive environments, you can choose metal junction boxes, such as those made of stainless steel and aluminum. This material has a low corrosion rate, can prevent rusting and degradation, and ensure a longer service life.

If you use a plastic electrical box, it should be capable of withstanding harsh environmental conditions such as UV rays and moisture, and be constructed strictly in accordance with the electrical environment.

IP Rating Requirements

Regardless of the material of the junction box, NEC specifies that it must have a certain degree of ingress protection(IP). The IP rating determines the ability to resist moisture and dust. This is crucial for electrical safety in outdoor, factory and humid production environments.

NEC 314.16—Volume Size of the Junction Box

NEC 314.16 detailed rules on the junction box of different wire types required minimum volume.The core is to ensure that there is enough room in the box for wires, connectors and equipment to avoid overheating, insulation damage or connection failure caused by overcrowding.

Method of Determining the Correct Volume

The NEC specifies that they use cubic inches to measure volume. Typically, the required volume is determined based on the number and size of wires that need to be contained inside the junction box, as well as any devices installed within it, such as fittings, switches, and outlets.

Box Fill Requirements

To ensure the reasonable wiring layout and electrical safety, the minimum size and volume of junction boxes required for different wire sizes and numbers are also clearly specified in the NEC code. For instance, a 18-cubic-inch junction box can accommodate at most three to six wires, while a 20-cubic-inch one can hold at most seven to eight wires.

NEC 370-29—Junction Boxes in Hazardous Locations

For the production of junction boxes in hazardous locations, targeted materials must be selected. This type of junction box is usually applied in environments with flammable gases and dust. Therefore, its production must comply with specific safety standards to prevent large-scale explosions.

Special Requirements for Hazardous Areas

For junction boxes in hazardous areas, they must be strictly sealed to prevent flammable gases from escaping from the boxes. It must also be explosion-proof. Even if there is an explosion inside, the jbox should not be damaged to avoid causing large-scale explosions or fires.

Furthermore, it also needs to prevent static electricity from igniting. Static electricity elimination is an essential function of it. Different junction boxes require clear labels, such as hazard markings and maximum temperature grades.

Installation Restrictions

Junction boxes must not be hidden in ceilings, walls, or inaccessible spaces such as attics, under-floor areas.

It must not be placed in areas where flammable gases or dust are likely to cause fires or explosions.

NEC 314.29—Junction Box in Non-Hazardous Locations

NEC Requirements

For junction boxes in non-hazardous areas, NEC clearly stipulates that they must be placed in easily accessible locations to facilitate maintenance and inspection. There should be no obstacles around the installation location, allowing for safe operation and maintenance. Moreover, the junction box needs to be firmly supported to prevent displacement and loosening caused by long-term use.

Cover Requirements

The cover needs to be firmly fixed, usually tightened with screws. It should not extend beyond the edge more than 1/8 inch at most, which can effectively prevent accidental electric shock.

NEC 250.110—Grounding Requirements

Section 250.110 stipulates the grounding standards for electrical equipment. This is an effective measure to prevent electric shock and fire by grounding the junction box, providing a safe path for the return of fault current. This measure mainly involves connecting the grounding conductor to the junction box.

Grounding for Metal Junction Boxes

The metal components inside the junction box must be connected to the grounding system. It should be noted that the grounding wire needs to match the size of the junction box. Metal junction boxes should be grounded by installing grounding screws in the threaded holes.

Grounding for Non-Metallic Junction Boxes

For non-metallic junction boxes like plastic, you still need to install them in the appropriate positions using compliant grounding clips or grounding conductors.Then, you should ground them in accordance with NEC’s compliant grounding methods.

NEC 110.26-Clearance Requirements

Section 110.26 mainly stipulates the safe distance between junction boxes and other electrical equipment and leaves reasonable and safe space for electricians’ operations.

Clearance Operation Requirements

The minimum working space in front of the electrical box is 36 inches deep. The depth space for conducting inspections and using operation tools is 30 inches. For safety and maintenance purposes,The NEC stipulates that a minimum headroom clearance of at least 6 feet must be kept, which is determined based on the voltage of the installed equipment.

Accessibility Rules

Your device door must be able to open at least 90 degrees to facilitate access to components and circuits. The workspace must be kept clean, with no obstacles blocking the passageways.

How to Avoid Common NEC Violations

Junction Box Overload

There are too many wires, connectors and devices inside the junction box, exceeding the marked volume of the box. It may cause equipment heat accumulation, leading to insulation aging and melting, and even triggering short circuits or fires. Therefore, you must calculate the required volume of the junction box by using the method of the number of wires. If you are not sure, you can choose a junction box with a larger capacity.

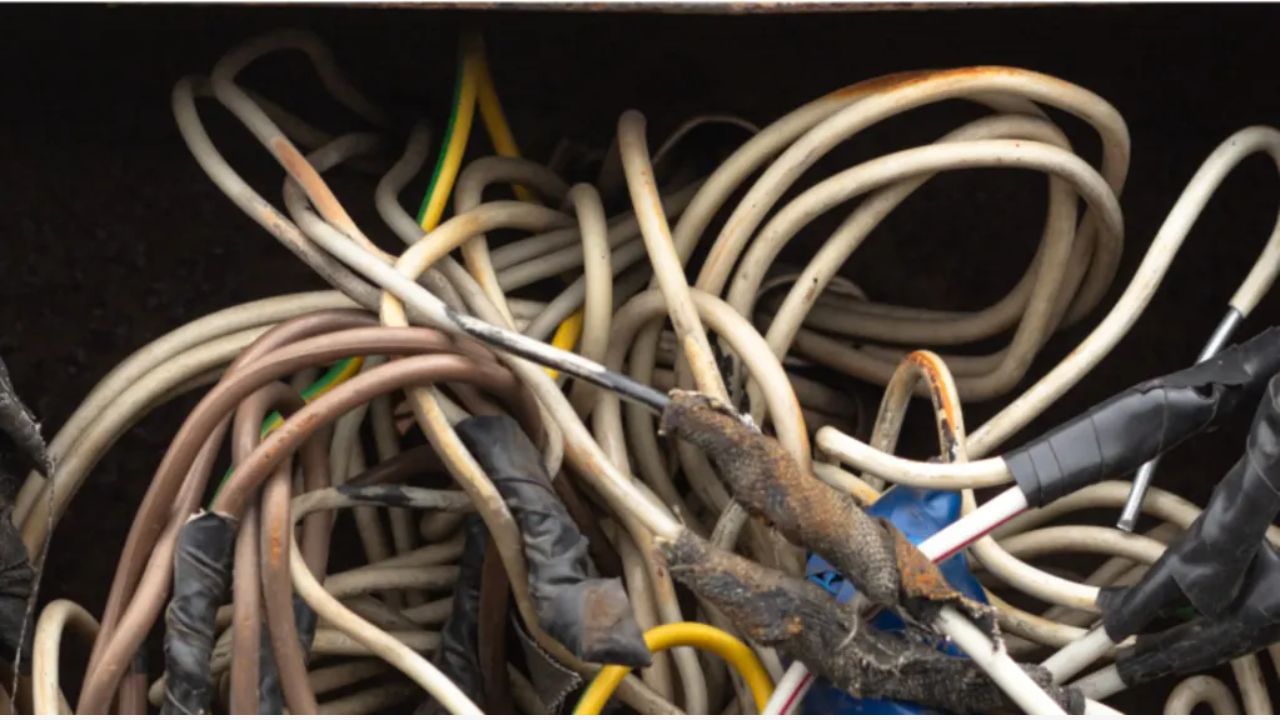

Improper Equipment Wiring

The equipment grounding wire of the metal box or tube groove is not connected, or is only wound on the grounding screw without using the correct terminal. A metal enclosure that has carried current for a long time can cause serious electric shock hazards when a grounding fault occurs. You should use the correct terminal blocks, clips or screws to guarantee a firm metal contact.

Using the Incorrect Type of Junction Box

For example, in a humid environment, use the junction box that is commonly used in a dry place. An improper junction box allows dust and moisture to enter the interior. Moisture may cause corrosion, short circuits and the risk of electric shock. You should always use specific junction boxes that comply with NEC standards to connect accessories.

Excessive Filling of Conduit or Cable Trays

If the cross-sectional area of the wire inserted into the conduit exceeds its maximum allowable filling rate, it will lead to poor heat dissipation, overheating of the wire and may damage the insulation. Therefore, calculating the appropriate filling rate of the conduit or choosing a larger conduit can improve heat dissipation and leave sufficient space for future line expansion.

FAQ

What Are the Differences for Enclosures Between NEMA and NEC?

NEMA is an industry standards organization. It mainly defines the product performance standards of enclosures, which are used to classify the physical properties of electrical enclosures, such as dust-proof, water-proof, and corrosion-resistant, etc. NEC is a regulatory safety installation specification that mandates the use of enclosures that comply with the corresponding NEMA grade in specific installations.

How to Choose a Junction Box of the Appropriate Volume?

According to NEC 314.16, you need to count all the components inside the box and calculate the number of wires they occupy in accordance with NEC code. Then, based on the maximum wire specification, determine the volume per unit of wire quantity. The volume of the junction box is preferably larger than the required volume.

Is the Covering Junction Box Safe and Complies with NEC Regulations?

Yes, the covered junction box is not only safe but also a mandatory requirement of NEC regulations. All junction boxes must be equipped with complete covers, which can prevent electric shock, prevent dust and moisture from entering and ensure the integrity of the electrical enclosure system.

It should be noted that the cover plate you choose needs to match the type of junction box and be suitable for the installation environment. The cover needs to be firmly installed to safely cover the opening of the box.

What Consequences can be Caused by Incorrect Grounding of the Junction Box?

It may cause fatal electric shocks or fires due to overheating of wires. Failure of fault voltage return to its source can lead to equipment damage. Most importantly, non-approved installations cannot pass electrical inspections and may result in fines or even legal liability.

Final Thought

A safe electrical installation not only requires following NEC standards but also using junction boxes that meet specifications for various scenarios. KDM is a professional manufacturer of custom electrical enclosures. We can custom-produce electrical enclosures from NEMA 1 to NEMA 13, fully meeting any of your customization needs. Fast response and comprehensive customization services are our distinct advantages in custom manufacturing. Welcome your inquiries to obtain a personalized solution.