- Custom Ip66 or Any IP rating Enclosure

- IP65/IP66 Certification

- Fast Sample Production within 3 days

Custom IP66 Enclosure Manufacturer in China

- KDM IP66 enclosure offers the highest protection against particles and is able to protect high levels from water, including powerful jet sprays and temporary flood conditions.

- IP 66 electrical enclosures can withstand 30 KPA water jets from 3 meters in any direction. Furthermore, it prevents contact with live or moving parts with the equipment, and against the ingress of dust. KDM enclosures stringently adhere to these standards, and you can expect superior quality and craftsmanship.

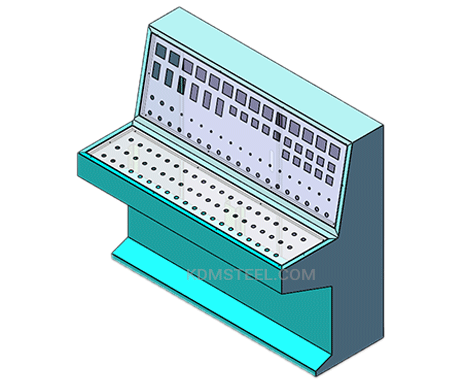

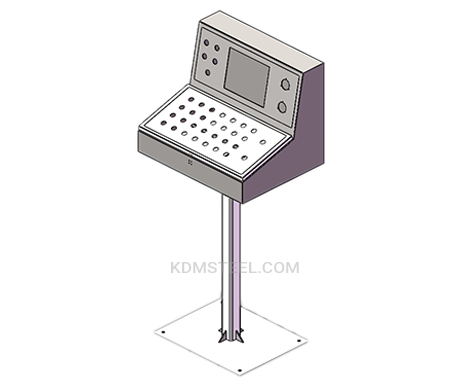

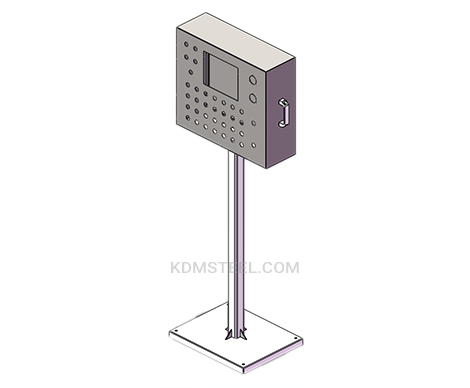

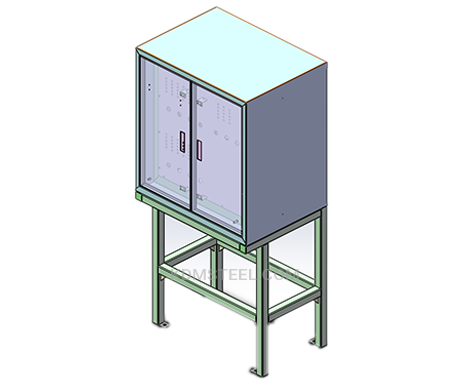

KDM IP66 enclosure Series

Send your Inquiry on KDM IP66 enclosure

KDM IP66 enclosure is specified for harsher indoor industrial or outdoor applications. These IP66 rated enclosures are ideal for your watertight projects.

IP66 electrical enclosure ensures your components are prevented in wet environments. The KDM IP66 enclosures have a locking catch that engages to positively hold the lid closed until disengaged.

- Manufacturing Capacity

- Buying Guide

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experienced workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

The expert assembling team, consistent assembly quality on every KDM enclosure

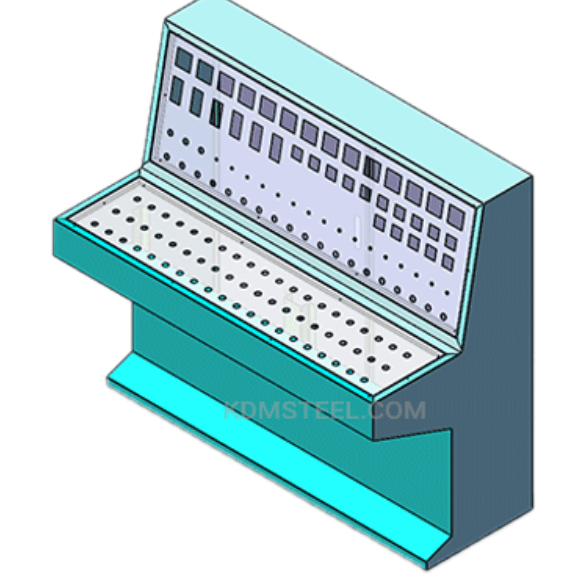

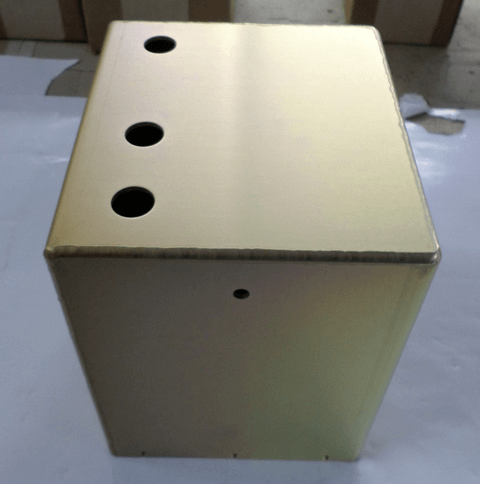

KDM IP66 Enclosure

KDM has a range of high-performance IP66 enclosure are available in different sizes and types, so you could easily find the right enclosure solutions for your needs. Our enclosures are manufactured to the highest quality standards which ensure consistent fit and finish on all batches. So you can be sure that every enclosure will conform to its IP rating. KDM designed electrical enclosure meeting IP66 standards to satisfy customer specific requirements.

Galvanized IP66 Enclosure

Stainless Steel IP66 Enclosure

IP rated 66 enclosures are offered in a wide array, including free-standing, modular, wall mounted, an enclosure with window, stainless steel, weatherproof, control panel, galvanized steel and more other types of enclosure.

For custom enclosure meeting IP66 standards, we can customize any of our enclosures with cutouts and printing. Any size or shape cutout can be added to all surfaces of our enclosures. Furthermore, insulation, hinges, latches or locks can be add-on according to your requirements.

At KDM, we are choosing an electrical enclosure based on your application and what qualities it requires to succeed. Examples of such qualities include corrosion resistance, thermal insulation, spark resistance, explosion resistance, low-temperature resistance, durability, security, etc. Our flexible engineering and manufacturing systems enable us to customize enclosures to save your valuable time and cost in your process, to populate the enclosure and install it.

At KDM, we cater to your needs and offer modified standard and custom IP66 enclosure products through step-by-step design support. Over the last 10 years, we are a trusted manufacturer for any types of electrical enclosures. Our professional engineering and designing team has developed enclosures to the standard required for IP66 enclosure. KDM is a 9001:2015 certified manufacturer of electrical enclosure based in China.

Our expertise in fabricating high-quality enclosure, leaned us to provide the best to our customers and grow as a company to a higher level. Our state-of-the-art manufacturing process ensures a quick turnaround without sacrificing the quality you expect from KDM IP66 enclosures.

By selecting KDM IP66 enclosure, you can benefit from outstanding quality products, fully finished enclosures that are ready for installation, individually modified based on your request and a high level of functionality and innovative strength. Our excellent knowledge and experience will let you receive the appropriate enclosure for your needs. Let us know your specifications and we will provide a competitive quote.

The Ultimate FAQ Guide to IP66 Enclosures

- What does IP66 mean?

- Why are there additional letters after the main IP code?

- What testing do IP66 enclosures undergo?

- What NEMA type is IP66 comparable to?

- Do IP66 enclosures protect against corrosion?

- Do IP66 enclosures protect against explosions?

- How and why do IP66 enclosures maintain inside temperature?

- How can I be sure of the quality of IP66 enclosures?

- Where can IP66 enclosures be used and for what applications?

- What designs of IP66 enclosures can I choose from?

- What features can I request for IP66 enclosures?

- What accessories can I request for IP66 enclosures?

- Do locks, windows, vents, and hinges lower the IP rating?

- How are enclosures made to have a high IP rating, such as IP66?

- What materials can be used for IP66 enclosures?

- What paints and coatings can be used for IP66 enclosures?

- How do you customize the symbols or writing on an IP66 enclosure?

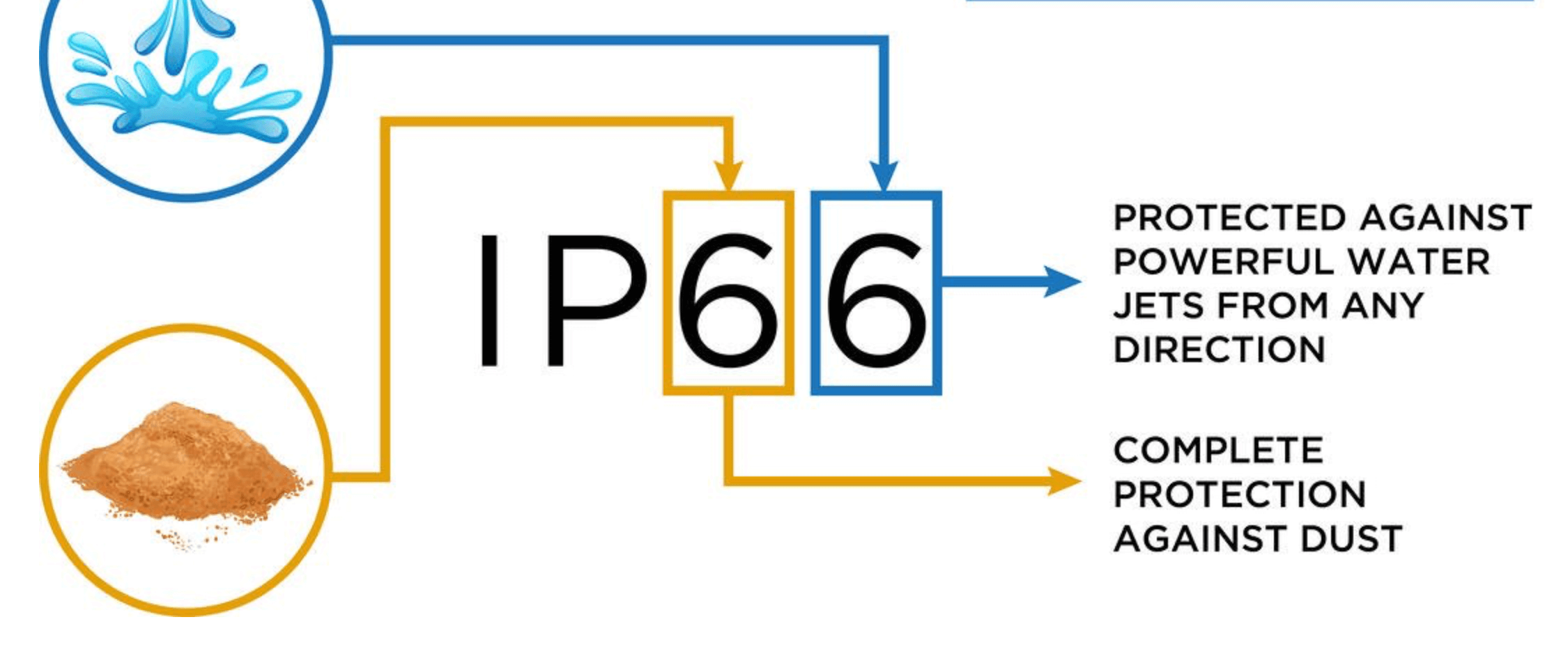

What does IP66 mean?

Enclosures rated with IP66 are fully dust-tight, and protect from low-pressure water jets from any direction.

High-pressure water jets can be measured at 100 liters per minute.

In the workplace, these could manifest as rainstorms, temporary floods, or water spray from nearby machinery.

This also means that IP66 enclosures are well protected against fog, humid air, oil and coolant leaks, and corrosion induced by moisture.

IP66 rating

Why are there additional letters after the main IP code?

As we already mentioned the “X” means that there is no available information, or that it is irrelevant or replaceable.

There are 2 sets of optional letters you can add after the digits.

The additional set – A, B, C, D – describes the protection of the enclosure against tampering.

A stands for protection against the back of a hand; B stands for protection against a finger; C stands for protection against access with a tool, while D indicates for protection against access with a wire.

The supplementary set of letters – H, M, S, W – tell the user what the enclosure is for.

H tells that the enclosure can serve for a high-voltage device; M indicates that the device inside the enclosure was moving during a water test, whereas S means the opposite – that it was standing still.

Finally, W means that the enclosure is weather-proof.

The full IP code

You can use these to indicate what features you want your IP66 enclosures to have.

These are mainly used for better communication between the client and the manufacturer.

What testing do IP66 enclosures undergo?

IP6X is tested using a closed space where a vacuum attracts a lot of dust and different powder that is blown all around to the enclosure for at least 15 minutes, and then the enclosure is checked for dust ingress.

Dust chamber testing

IPX6 is tested using spray nozzles, measured at 12.5mm, with oscillating tubes that pressurize and spray water at 100 liters per minute for at least 3 minutes in any imaginable angle from a distance of 3 meters.

Some submersion is also possible since these enclosures need to withstand temporary flooding up to 1 meter for about 30 minutes.

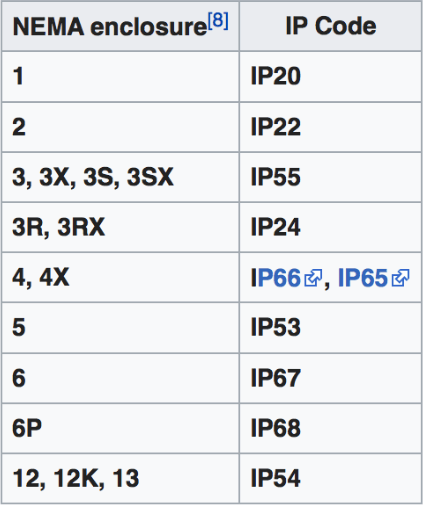

What NEMA type is IP66 comparable to?

As for NEMA, we offer any type, starting with 1 and up to 13, including subtypes, such as 3X.

Our NEMA enclosures are protected against weather, corrosion, coolant seepage, chemicals, and much more.

IP ratings and NEMA types cannot be directly converted into one another, but they can be loosely compared as shown below.

NEMA and IP ratings comparison

As the table shows, IP66 can be compared to NEMA 4 and 4X.

These types provide high degrees of protection from weather, including ice and sleet.

Type 4X has additional corrosion-resistant qualities.

Do IP66 enclosures protect against corrosion?

IP66 is not fully waterproof, so it may not protect against corrosive agents if they are strongly sprayed on it or submerged in.

If they are just splashed, or even sprayed, then there is no problem, but corrosive fumes may still get in.

The material plays its role as well – aluminum and stainless steel are the most corrosion-resistant materials.

Feel free to scroll down to learn more about different materials!

Do IP66 enclosures protect against explosions?

IP66 enclosures are not designed to contain an explosion or an arc flash.

They are not comparable to NEMA types 7, 8, 9, or 10.

These enclosures need to withstand high impacts and high temperatures.

As for arc flash, enclosures typically can’t protect from that, so personnel needs to keep that in mind.

However, if you need an explosion-proof enclosure, contact us and we will engineer it for you!

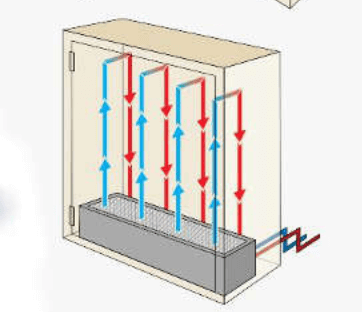

How and why do IP66 enclosures maintain inside temperature?

KDM IP66 enclosures can be equipped with double-wall technology, a thermal chamber, insulation, heat strips, heat exchangers, and vents with air conditioning.

All this provides protection from the electrical heat and solar radiation to prolong the life of electrical components within the enclosure.

Heat exchanger

If you plan to install IP66 enclosures in a cold environment, then we can also include small heaters, so the electrical components don’t freeze or slow down in work.

Heater Strip

Plus, thermal management reduces hot spots, equalizes pressure, and minimizes condensation, which can damage electronics and various devices.

How can I be sure of the quality of IP66 enclosures?

We have a certification you can look through, which will give you more details about and confidence in our enclosures.

Where can IP66 enclosures be used and for what applications?

IP66 enclosures can be used both indoors and outdoors.

IP66 enclosures are commonly used in industry and factory

machinery and equipment, heavy-duty construction, swimming and spa pools, bathrooms, transformers, and medical equipment.

Other applications may be telecom cabinets or control boards, among other things.

IP66 enclosure

IP66 enclosures are especially great for control boards since they provide superb security both from the environment and from tampering.

And such security is perfect for important electrical components.

Industrial PCs are often housed in IP65 and IP66 enclosures.

Then, other devices may be included as well, such as bar code scanners, USB hubs, and RFID receivers.

This IP rating is perfect for outdoor environments because it is dust-tight and rain-proof.

The dust-proof and water-resistant qualities make it possible to be put underground, fully or partially, if you are catering to gardening applications.

What designs of IP66 enclosures can I choose from?

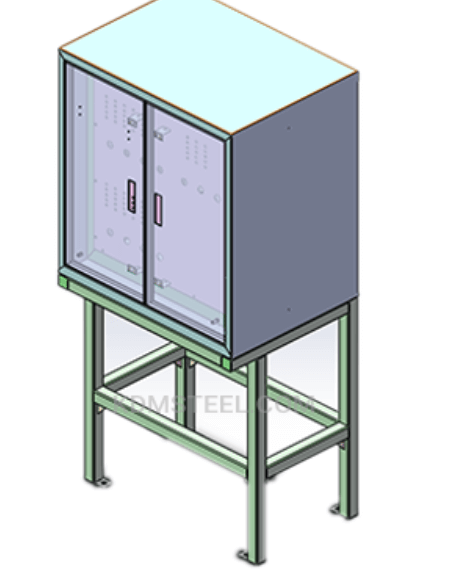

We are delighted to offer you a range of designs of free-standing enclosures, wall-mounted enclosures, junction boxes, modular enclosures and custom enclosures.

Free-standing enclosures are perfect for large electrical units that are too heavy to be wall-mounted or pole-mounted.

They could be of any height and width. They are also portable, and can be big enough to be categorized as walk-in enclosures.

Free-standing enclosure

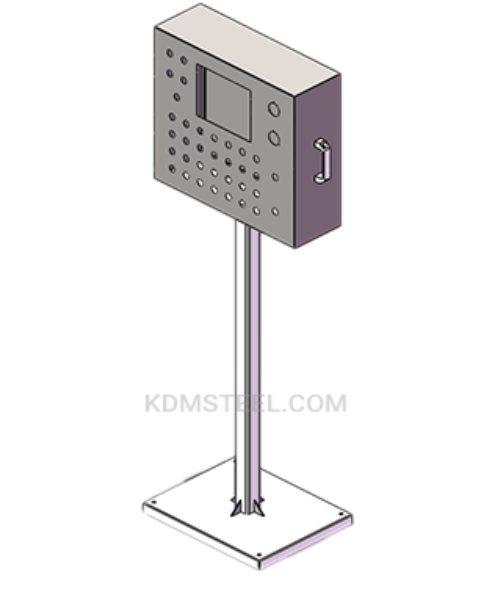

Wall-mounted enclosures use mounting brackets, screws, and pads for installation.

They are perfect for small devices in public places, as well as anywhere where space is a concern.

These can also be pole-mounted with special circular brackets.

Wall-mounted enclosure

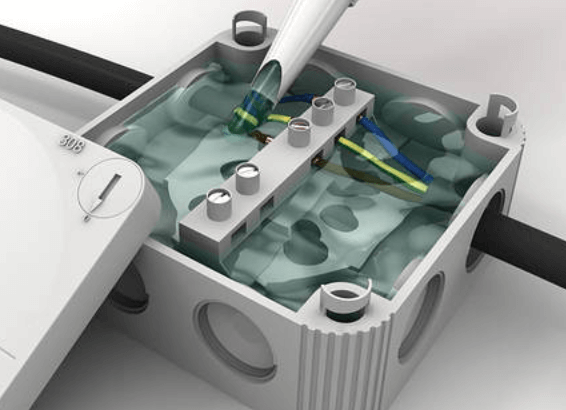

Junction boxes are enclosures with a lot of wires that all interconnect.

Such boxes are usually used for control boards, so they need to be protected with IP65 and up.

They also often have pedestals, which help in case of flooding, so this is another thing to consider.

Junction box

Modular enclosures are similar to custom since they allow for flexible configurations.

You can add or remove walls and doors as you need, varying the size and shape of the enclosure.

Having these in IP66 provides a great deal of flexibility and security, so you have less things to worry about.

Of course, we also have our custom enclosures, which can be of any design, shape, and requirements, as well as have multiple doors.

Custom IP66 enclosure

This includes piano-type control boards, various electrical boxes, cabinets, and enclosures on pedestals.

Just reach out, and we will be happy to create your perfect custom enclosure!

What features can I request for IP66 enclosures?

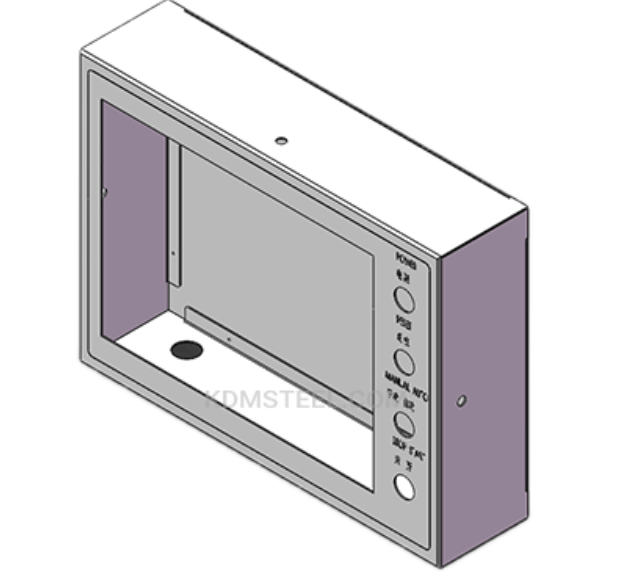

You can request vents, windows, hinged doors, locks, cable management systems, and much more.

Vents, as well as radiating fans, provide a path for heat to escape through, cooling electrical components of the enclosure.

This prolongs their life and decreases the possibility of malfunctions.

Radiating fan in an enclosure

These also stabilize air pressure inside the enclosure, preventing condensation which can damage the electrical components of the enclosure.

Plus, the vents can be further upgraded to air conditioners and heat exchangers.

Windows help personnel examine the electrical components in a quick and non-invasive way.

And if something goes wrong, a window helps to see what is happening right away.

Plus, infra-red windows help protect workers from arc flash accidents.

Enclosure with a window

Hinged doors control how and how much the door or cover of the enclosure opens.

This also includes a variety of handles that you can request as well.

Locks add a layer of security to your IP66 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Lock

What accessories can I request for IP66 enclosures?

Cable management systems such as cable entry frames and clamps serve to keep wires organized and make them easier to install and maintain.

Solar shields are basically another layer on top of an enclosure that reflect solar radiation, controlling inner temperature of the enclosure to prolong the life of its electrical components.

Solar shield (the top plate)

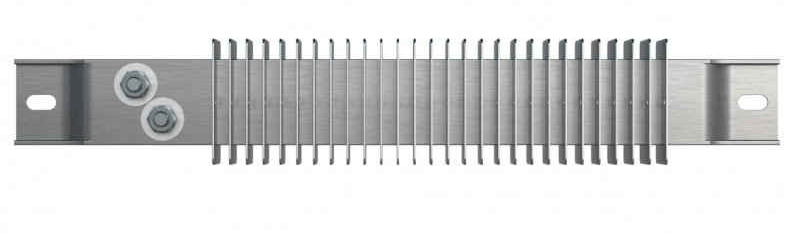

DIN rails are used to mount circuit breakers in equipment enclosures used in industrial applications.

Rain caps are slanted roof-like top pieces that make water slide off the side of the enclosure, thus protecting it from water ingress.

IP66 enclosures benefit especially much from this feature, prolonging its life outdoors.

IP66 rain cap with lifting eyes

We also make casters, thermometers, light switches, lifting eyes, operator devices, and purpose-specific features like keypads and heat exchangers.

To learn more, feel free to contact us for more information about all the different features and accessories we offer! We will also provide any custom feature you request.

Do locks, windows, vents, and hinges lower the IP rating?

Yes, features like vents, windows, and locks do somewhat compromise the IP rating, but there are ways around it.

But KDM overcomes this difficulty, offering you some of the best enclosures for your business.

We incorporate various gaskets, PU seals, latches, and filters to balance out the IP rating.

How are enclosures made to have a high IP rating, such as IP66?

The most vulnerable place in an enclosure is between its body and its lid – here is where dust and moisture can creep in.

However, KDM designs sealing gaskets that are either moulded or screwed in place flush against the surface.

PU sealing gaskets

Medium IP ratings are often equipped with a ‘push-click’ mechanism in the lid.

This makes it quicker to use, but allows for a small degree of gasket movement once closed.

To achieve a high IP rating, some enclosures are filled with a silicone gel that sets and prevents any moisture or dust from coming into contact with the electrical components.

Gel-filled IP66 Enclosure

This allows for the enclosure itself to be cheaper, but it also means that the components will not be easily accessible.

So, if you need an accessible and secure enclosure, IP66 is the way to go.

What materials can be used for IP66 enclosures?

The materials used for IP66 enclosures aren’t different from materials used for other types of enclosures.

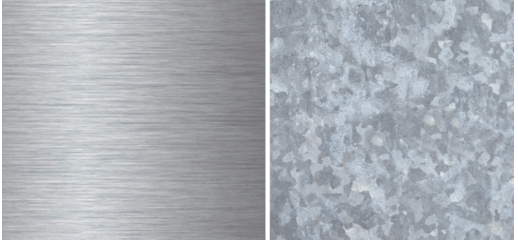

They can be made from carbon steel, galvanized steel, and stainless steel – usually of the grades 304, 316, or 316L.

Carbon steel is usually duller than stainless steel.

It is also magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion.

Stainless steel is created by adding chromium, nickel, and molybdenum to the iron-carbon alloy.

Stainless steel vs. galvanized steel

Steel grades 304 and 316 differ in the content of all additives.

Grade 316 is slightly stronger and resistant to saline and acidic water because of molybdenum.

But grade 304 is cheaper and more common.

Grade 316L has a lower carbon content, making it a little bit stronger.

Galvanized steel is coated with a protective layer of zinc that prevents corrosion.

We have galvanized steel enclosures, and this metal is vulnerable to salt water.

Please note that galvanized steel is more expensive and heavier than stainless steel.

Another type of steel that can be used is cold-rolled steel, which is thinner and more dense than normal steel – and thus, it is stronger.

Fiberglass is very strong, can dissipate heat, and insulates electricity, lowering the effect of interference and the possibility of shock.

It is made from glass fibers placed in plastic.

Fiberglass enclosure

Also, our windows are made from polycarbonate and ABS.

Polycarbonate is more resistant to corrosion, whereas ABS is cheaper.

IP66 enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys, but can be depending on what you are going for and what are your needs.

Just like steel grades, aluminum alloys can be either of the 5052 or the 6061 series.

Aluminum vs stainless steel

Both are lightweight, but 5052 is more weldable, whereas 6061 has a higher resistance to corrosion.

Also, 6061 is more expensive.

Aluminum has a layer of oxide on top that prevents any corrosion.

This material is especially good for enclosures exposed to solvents, petrochemicals, some acids, most sulfates and nitrates.

So, if you are looking to put IP66 enclosures in such mildly hazardous environments, aluminum is good for that.

If you would like to learn more, send in your inquiry now for a consultation!

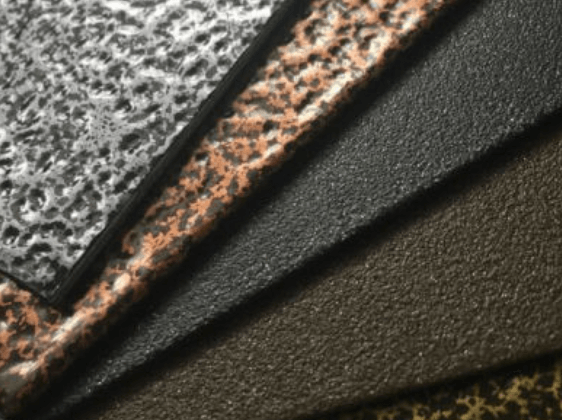

What paints and coatings can be used for IP66 enclosures?

Our enclosures are well-protected, but the right coating can add its protection as well.

You can choose enamel or powder paint coats in any color.

Enamel paint has a glossy finish and is resistant to different weather conditions.

Specific enamel paints like epoxy enamel and PU enamel are commonly used for industrial enclosures since they are resistant to corrosion.

Powder paint is deposited with the electrostatic force, and is quicker and easier than enamel.

It is also more flexible in appearance, giving you the option of glossy and matte finishes.

Powder coating finishes

We also offer anodizing and alodining coatings.

Anodizing coating uses anodes to oxidize a metal, usually aluminum, to increase its thickness for better corrosion resistance.

Steel is not typically anodized because it can actually speed up the corrosion of the metal.

Alodine coating, also known as the chromate conversion coating, is used to prime steel and aluminum for paint, as well as prevent corrosion.

Alodine coating

This is a cheaper process than anodizing, and can be recognized by its characteristic greenish-yellow hue, unless it is painted over.

There can also be anti-graffiti and anti-poster coatings to protect your IP66 enclosure from vandalism.

We can provide any coating in any color and finish, so contact us today!

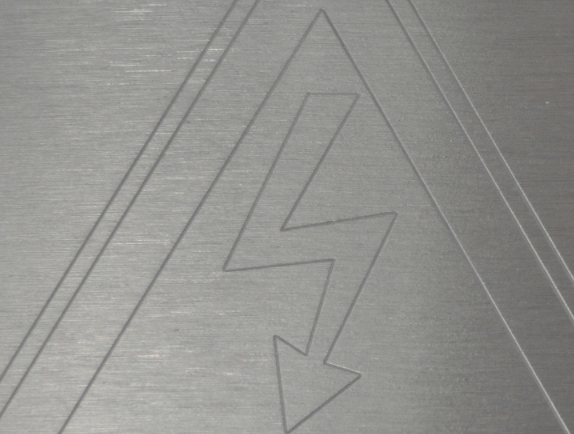

How do you customize the symbols or writing on an IP66 enclosure?

Our customizing services include engraving and silk-screening.

Silk Screening is the easiest and most affordable method of customization.

Any flat side of the enclosure can be silk-screened with labels, warnings, serial number, your company name and logo.

However, silk-screening on metal like stainless steel or aluminum can be worn off or scratched off, but a clear powder coat helps to prevent that.

Silk screening

Engraving the enclosure is another method of customizing your enclosures.

This option is more costly and takes more time, but it is also more long-term than silk-screening.

A little bit of metal is removed from the surface of the enclosure in the design of the logo or symbol.

Usually, about 0.005 inches or 0.010 inches of metal is removed from the surface.

Once the metal has been removed, it is filled in with epoxy paint of any color to match your requirements.

Engraving

Recent IP66 enclosure Order

Marine Electrical Enclosure – Your Ultimate FAQs Guide

What is a Marine Electrical Enclosure?

Marine Electrical Enclosure is designed to withstand the harshest maritime constraints. It is built to last for a long time.

It provides security from elements such as dust, wind, water, and chemicals. It is engineered to survive in high temperatures.

Marine Electrical Enclosure provides comprehensive barrier protection and leak prevention for the equipment inside.

It is primarily utilized in a waterproof marine environment and it is also be tough on its own.

What are the Functions of a Marine Electrical Enclosure?

Marine electronic enclosure can be used in a series of things, in fact, in almost all day-to-day operations these days.

The marine electronic enclosure can be used for a range of functions ranging from storage to packaging and much more.

Marine electronic enclosure protects internal electrical & mechanical elements in any setting especially in marine aspects.

It is built to last and are particularly created to surpass numerous prerequisites, makes them perfect in any application.

It is used in application domains in which delicate machinery or connection points require extra security.

It is commonly used in marinas to:

- Store power cables and infrastructural facilities

- House wireless connections or base stations

- Secure gate operating systems or other connection control devices

- House a security system completes with cameras

What Security Features does this Marine Electrical Enclosure Provide?

Because of their environmentally sealed nature, this enclosure aids in the prevention of fire if one occurs within the compartment.

It serves an important special purpose by lowering the risk of fire propagation, which can ultimately save lives.

Marine Electrical Enclosureis long-lasting, high-quality and is built to withstand the marine environment.

Other Features:

Apart from security features, Marine Electrical Enclosurealso have a wide range of characteristics such as the following:

- Fuse holders that are water resistant for safety precautions.

- Fully water resistant and high-quality steel materials are used in the construction process.

- Kits include everything you need, including a water resistant cord glands, and an adapters block with mounts.

- Simple to use, simple to set up and a wide range of compositional accessories are available.

- It has intrinsic connectivity wiring blocks, busbars and includes air circulation screensand shade structure.

- Port selection is flexible and fit the provided glands to ensure water resistant authenticity.

- Designs are made to orderand is ideal for marine applications.

- It has universal mounting brackets for walls and poles and the back plate configurable and detachable.

- It has surveillance camera lock, foam stripping for weatherproofingand insulation.

- These multifunctional storage boxes are heatproof and can be customized.

- These have tight-fitting lids and distinct molded handles for a strong grip.

- It has personalized screen printing and cutouts to windows and a variety of sizes.

- Variant with a glass roof for outdoor use, preserving the seal’s quality.

- There are a lot of installation options and numerous coupling options.

- Combination of the four versions, each with three different types of doors and a rear door instead of a panel.

What Materials Does a Marine Electrical Enclosure is Made of?

Marine Electrical Enclosure is made of durable polymeric materials that are good enough to defend the objects kept within them.

It is made of aluminum and captive stainless-steel fixings and offers excellent resistance to corrosion and ingress protection.

Marine Electrical Enclosure can also be available in plastic, aluminum, and steel.

It can be machined and squeezed with a variety of thread forms and is excellent for extensive machining on all sides.

What are the Benefits and Advantages of a Marine Electrical Enclosure?

It comes in a variety of forms, dimensions, colors, and designs that can perfectly fit your needs while also saving money.

These marine electronic enclosures are inspected and tested to guarantee best performances and itis extremely useful.

Here are its additional benefits and advantages:

- It is extremely dependable and durable.

- It is suitable for professional advanced manufacturing use with excellent corrosion resistance.

- It safeguards the silicon seal and keeps contaminants out of the main enclosure.

- It keeps electrical & electronic devices secure in damp environments.

- It is perfect for marketing or recreational marine applications and in the hottest engine rooms.

- It is ideal for new installations as well as substituting devices on your boat.

- It has long-lasting polycarbonate composition and deteriorates rusts over time.

- It is eco-friendly and fashionable.

- It is built with highly specialized technologies that enable them to last a long time.

- It is particularly developed and produced for clean and easy integration.

- It stands out because they are extremely durable and built to last.

- It is light weight that allows for simple installation and has a strong resistance to shocks.

- Longevity without the need for maintenance.

- There are no electrical contact hazards and it is really resistant to harsh environments.

- It is suitable for both indoor and outdoor use and can be used across a wide temperature range.

- It is UV resistant and immensely powerful, with abrasion resistance.

- It has polyester enclosure on the floor.

- Machining is simple, and there is no corrosion as a result of the process.

In What Industries Does Marine Electrical Enclosure Widely Serve?

Marine Electrical Enclosure is used by professionals all over the industry and are a very worthwhile investment.

It is used in a wide range of industries including the following:

- Solar and Wind Power

- Agricultural Production

- Oil and Gas

- Food and Beverage

- Marine

- Pumping Water

- Aquarium Filtering

- Car Industry

- Energy Industry

- Medical Industry

What Ratings Does Marine Electrical EnclosurePassed?

Marine Electrical Enclosure has been rigorously tested and have managed to pass all of the following benchmark tests:

- International IP and NEMA performance standards

- UL/CUL Requirements

- Rohs Regulations

- Chemical Resistance is Excellent.

- Atex Requirements

- Exceptional Impact Ratings

- UV Characteristics

What are the Essential Components Inside a Marine Electrical Enclosure?

Marine Electrical Enclosure is capable of housing intrinsic devices that contains the following components:

- Wiring Harness for Heavy Duty

- It is responsible for convenient and simple service delivery.

- It guarantees the consistency of all electrical power and signal circuitry.

- Capacitors with Soft Start

- These devices safeguard the compressor and fan motors against opening cycle surge voltages.

- Itconstrains energy spikes in the air conditioning unit circuitry.

- Thermal Overload Protection for Motors

- It is used to meet potentially dangerous location requirements.

- It is properly sealed and act to cut power when excessive winding temperature is detected.

- Thermal Overload Protection for Compressors

- This device safeguards the cooling system by evaluating head temperature and flow of current.

- It avoids compressor temperature fluctuations and premature failure.

How to Choose the Proper Size of a Marine Electrical Enclosure?

The size of your application is the most essential factor to consider when choosing a Marine Electrical Enclosure.

It’s a simple technique to choose the correct one once you know the size of your area and the parts that will go in the enclosure.

It will give you lots sufficient space both inside and outside to allow for some wiggle room.

The last thing you want is for everything to be stuffed in so tightly that it puts strain on connectors or terminals.

When choosing your enclosure, another thing to be certain of is the safety features it includes.