Professional IP electrical enclosure manufacturer in China, supply you custom enclosure from IP44 to IP68.

Weatherproof solution for your industry electronics system.

Guaranteed production with several party testing reports before shipping.

Your First Choice for IP 65 Enclosure Manufacturer

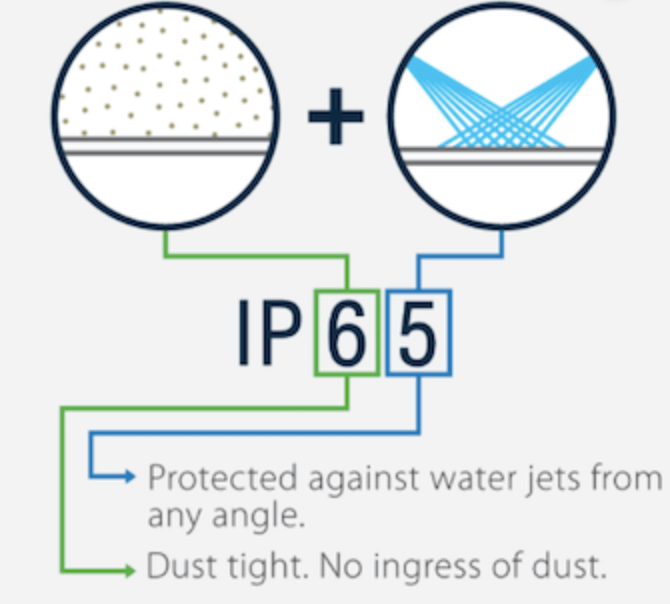

KDM IP65 enclosure provides complete protection against dust or any materials to enter the enclosure. This enclosure is mostly placed outside, so you could guarantee, it won’t be easily damaged.

This type of enclosure also offers enough protection to the people from accessing the component as it poses a lot of danger to them. In addition, IP65 prevents any water from getting in and damaging the circuit breakers.

KDM IP65 Enclosure Series

Stainless Steel electrical enclosures are KDM’s star products. KDM has been focusing on the manufacturing of stainless steel electrical enclosures for almost two decades.

KDM mild steel enclosure is designed for a wide range of industrial environments including road, motorway, rail and underground tunnels, offices, hotels and public buildings, and major infrastructure projects.

Galvanizing is the process where a layer of protective zinc coating is applied onto the steel surface so that the steel will become immune to rust.

One Stop Protection Solution

At KDM, we thoroughly test our enclosures and cases according to official IP65 standards. Even the most sensitive of your electrical and electronic appliances will be safe during stormy weather.

IP65 electrical enclosures offer immense versatility in resisting any-size debris, dirt, windblown dust, and low-pressure water jets. As such, the KDM IP65 enclosure box performs well in a variety of applications: domestic, commercial, industrial, agricultural, energy, and more.

Wide Applications for Your Industry

IP65 electrical enclosures offer immense versatility in resisting any-size debris, dirt, windblown dust, and low-pressure water jets. As such, KDM IP65 enclosures perform well in a variety of applications: domestic, commercial, industrial, agricultural, energy, and more.

Whether you need enclosures for a factory or a restaurant, KDM IP65 cases are a good bet. The assemblies you can house in them include motors, telecommunications equipment, cables, fuse boxes, and other devices.

Quality IP Enclosure Manufacturing

KDM has been the leading electrical enclosure manufacturer for over 10 years. Quality is assured with KDM’s certification to ISO 9001:2015. All our heavy-duty enclosures are also RoHS compliant.

At KDM, we are justifiably proud of our electrical enclosure meeting IP65 standard products, and we will strive to give you an electrical enclosure exactly what you need.

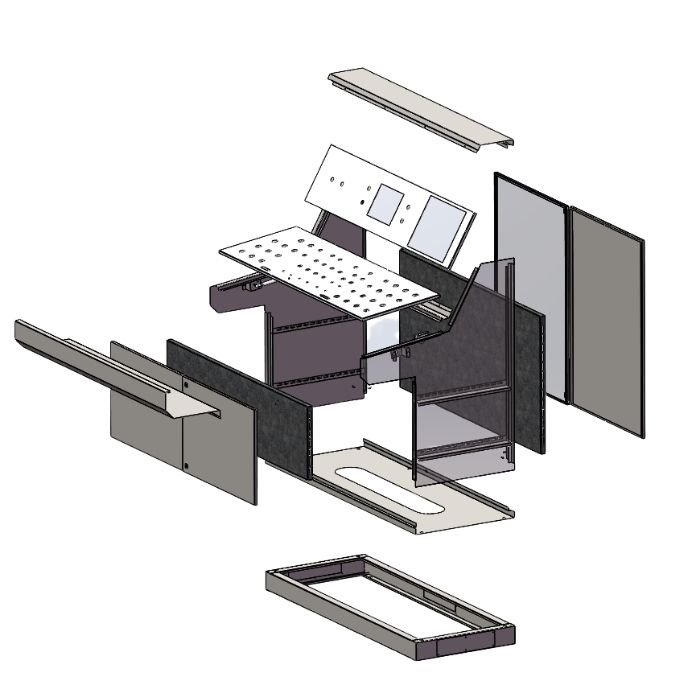

Advanced Enclosure Box Manufacturing Equipment

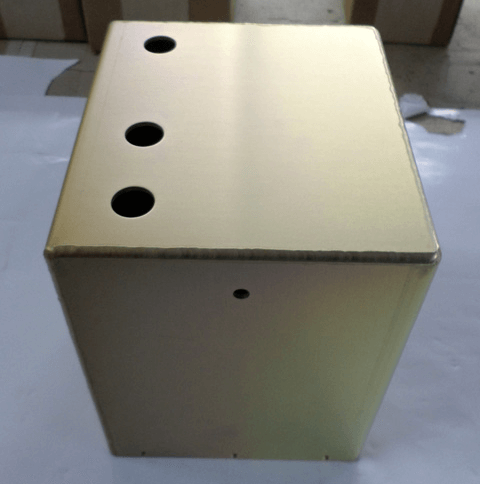

KDM IP65 enclosure has a rubber gasket around the inside of the lid which forms a dust and moisture-resistant seal, thus making the enclosure essentially waterproof. KDM produces a wide selection of different types of enclosures for electronics that met IP65 standards in various demands.

At KDM, our enclosure modern design provides high-quality electrical enclosures for any desirable applications that can be easily customized to meet IP65 standards at a competitive price.

More Options for Your IP65 Enclosure

KDM can provide custom services such as silk screening, anodizing, or engraving. Can also be custom with cutouts, insulation, hinges, latches, or locks. Our advanced manufacturing process ensures our customers get a quality enclosure that matches their exact requirements.

With our detailed and accurate design engineering excellence and through producing the highest quality IP65 rated electrical enclosures, we gain customer satisfaction.

More Manufacturing Process for KDM IP65 Enclosure

KDM manufactures a wide range of IP-rated enclosures. Some of our most popular products are the IP65 rated enclosures. They are moderately waterproof, shielding your electrical appliances from indoor and outdoor hazards. Specifically, KDM IP65 electrical enclosures guarantee protection against water jets. Plus, our IP65 enclosures are fully dust-tight.

KDM offers IP65 rated boxes and enclosures made with stainless steel, mild steel, aluminum, You can choose from a wide range of designs, sizes, and dimensions to pick the right IP65 enclosure for your application. IP65 doesn’t suit your needs? Take a look at all the other IP-rated boxes we offer!

Why KDM is Trusted By Over 1000 Global Clients

- Enclosure Manufacturing

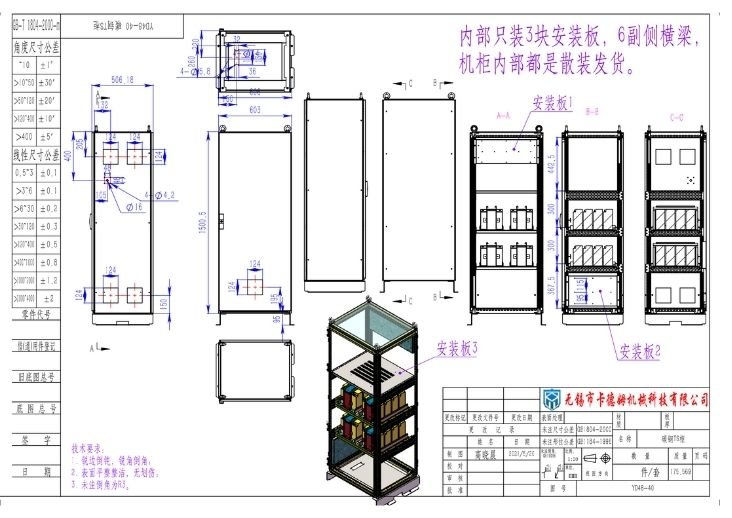

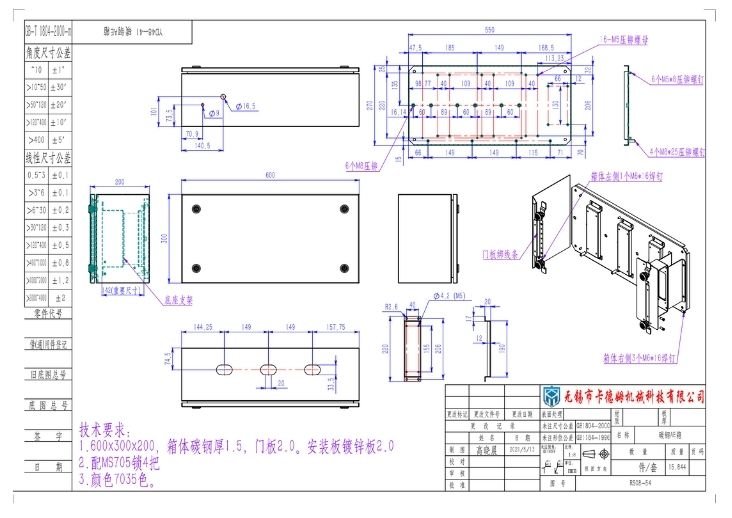

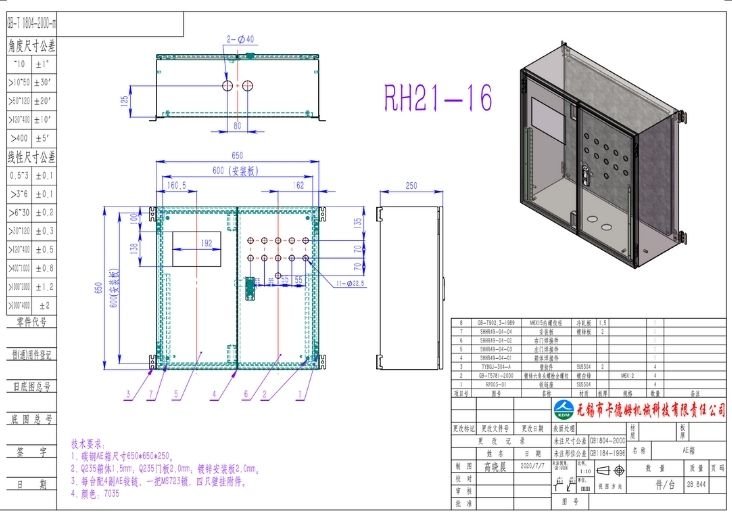

- 2D Drawing

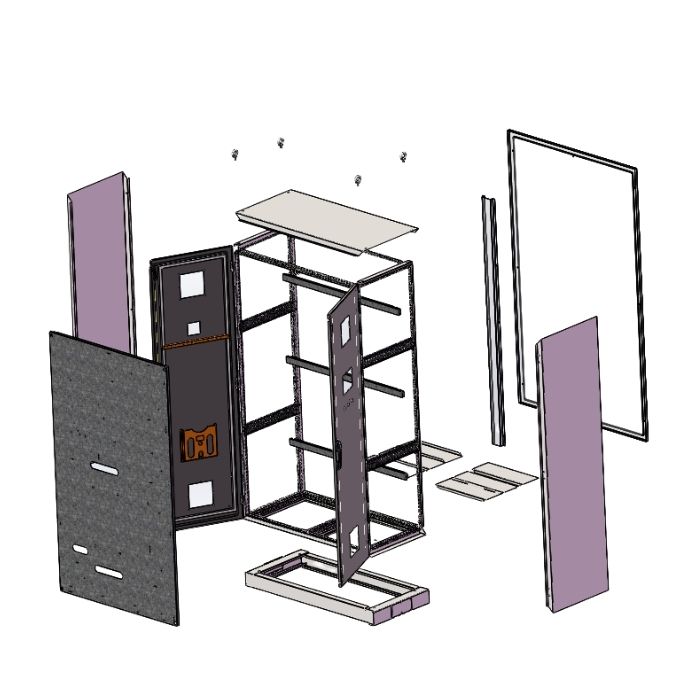

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure

Related Product

Resources

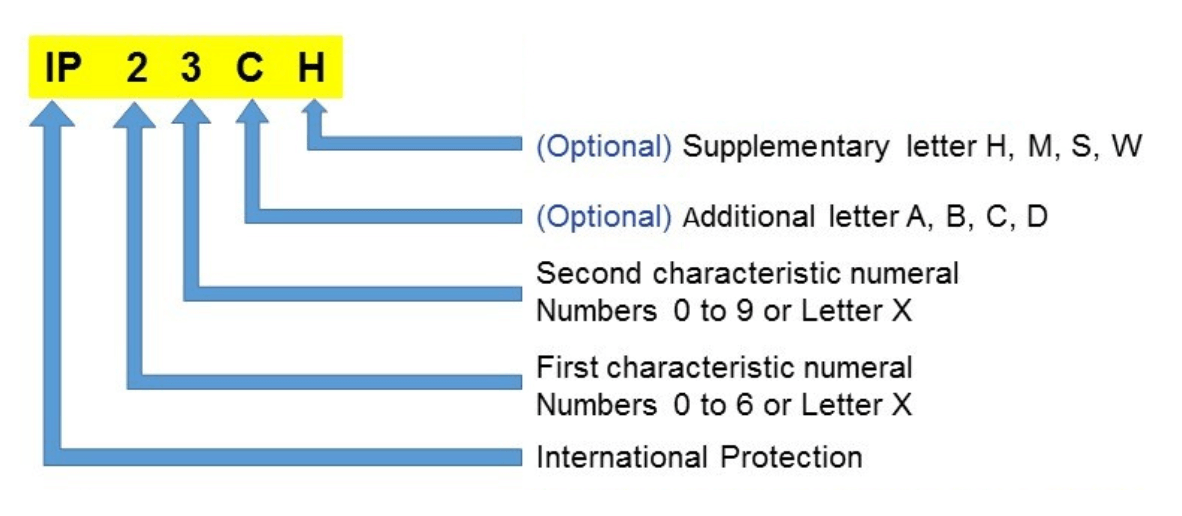

What is IP Rating? (Ingress Protection Rating)

KDM IP65 Enclosure

Over the last 10 years, we continue to develop and design a broad IP-rated enclosure, to provide you the most effective and comprehensive solutions for an array of projects.

With our high-standard electrical enclosure, you can enjoy the satisfaction of working with us, as your reliable partner, who support you along the process. Send us your inquiry and we will happy to answer any of your concerns.

The Ultimate FAQ Guide to IP65 Enclosures

- What does IP65 mean?

- What is associated with the letters after the main IP code?

- What testing do IP65 enclosures undergo?

- What NEMA type is IP65 comparable to?

- How can I be sure of the quality of IP65 enclosures?

- Do IP65 enclosures protect against explosions?

- Do IP65 enclosures protect against corrosion?

- How do IP65 maintain inside temperature?

- Where can IP65 enclosures be used and for what applications?

- What is the difference between IP55 and IP65?

- What designs of IP65 enclosures can I choose from?

- What features can I request for IP65 enclosures?

- What accessories can I request for IP65 enclosures?

- Do locks, windows, vents, and hinges lower the IP rating?

- What materials can be used for IP65 enclosures?

- What paints and coatings can be used for IP65 enclosures?

- How do you customize the symbols or writing on an IP65 enclosure?

What does IP65 mean?

Enclosures rated with IP65 are fully dust-tight, and protect from low-pressure water jets from any direction.

High-pressure water jets can be measured at 12 liters per minute and could be rain, or water spray from nearby machinery.

Also, IP64 enclosures work well in places with fog, humidity, oil, and corrosion.

IP65 enclosure

What is associated with the letters after the main IP code?

As we already mentioned the “X” means that there is no available information, or that it is irrelevant or replaceable.

There are 2 sets of optional letters you can add after the digits.

The additional set – A, B, C, D – describes the protection of the enclosure against tampering.

A stands for protection against the back of a hand; B stands for protection against a finger; C stands for protection against access with a tool, while D indicates protection against access with a wire.

The supplementary set of letters – H, M, S, W – tell the user what the enclosure is for.

H tells that the enclosure can serve for a high-voltage device; M indicates that the device inside the enclosure was moving during a water test, whereas S means the opposite – that it was standing still.

Finally, W means that the enclosure is weather-proof.

The full IP code

You can use these to indicate what features you want your IP65 enclosures to have.

These are mainly used for better communication between the client and the manufacturer.

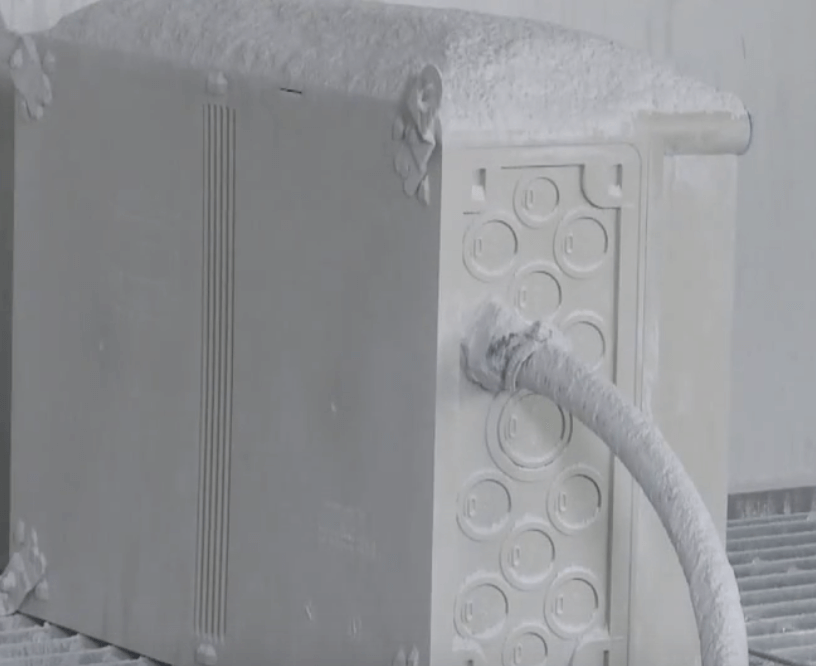

What testing do IP65 enclosures undergo?

IP6X is tested using a closed space where a vacuum attracts a lot of dust and different powder that is blown all around to the enclosure for at least 15 minutes, and then the enclosure is checked for dust ingress.

Dust chamber testing

IPX5 is tested using spray nozzles, measured at 6.3mm, with oscillating tubes that pressurize and spray water at 12.5 liters per minute for at least 3 minutes in any imaginable angle from a distance of 3 meters.

IP65 enclosures can also be submerged underwater for 2 minutes.

What NEMA type is IP65 comparable to?

As for NEMA, we offer any type, starting with 1 and up to 13, including subtypes, such as 3X.

Our NEMA enclosures are protected against weather, corrosion, coolant seepage, chemicals, and much more.

IP ratings and NEMA types cannot be directly converted into one another, but they can be loosely compared as shown below.

NEMA and IP ratings comparison

As the table shows, IP65 can be compared to NEMA 4 and 4X.

These types provide high degrees of protection from the weather, including ice and sleet.

Type 4X has additional corrosion-resistant qualities.

How can I be sure of the quality of IP65 enclosures?

We have a certification you can look through, which will give you more details about and confidence in our enclosures.

Do IP65 enclosures protect against explosions?

IP65 enclosures are not designed to contain an explosion or an arc flash.

They are not comparable to NEMA types 7, 8, 9, or 10.

These enclosures need to withstand high impacts and high temperatures.

As for arc flash, enclosures typically can’t protect from that, so personnel needs to keep that in mind.

However, if you need an explosion-proof enclosure, contact us and we will engineer it for you!

Do IP65 enclosures protect against corrosion?

IP65 is not fully waterproof, so it may not protect against corrosive agents if they are strongly sprayed on it or submerged in.

If they are just splashed, or even sprayed, then there is no problem, but corrosive fumes may still get in.

The material plays its role as well – aluminum and stainless steel are the most corrosion-resistant materials.

How do IP65 maintain inside temperature?

KDM IP65 enclosures are equipped with double-wall technology, a thermal chamber, insulation, heat strips, heat exchangers, and vents with air conditioning.

All this provides protection from the electrical heat and solar radiation to prolong the life of electrical components within the enclosure.

Heat exchanger

Plus, thermal management reduces hot spots, equalizes pressure, and minimizes condensation, which can damage electronics and various devices.

Where can IP65 enclosures be used and for what applications?

IP65 enclosures can be used both indoors and outdoors.

IP65 enclosures are commonly used in industry and factory

machinery/equipment, heavy-duty construction, swimming and spa pools, bathrooms, transformers, and medical equipment.

Other applications may be telecom cabinets or control boards, among other things.

This IP rating is perfect for outdoor environments because it is dust-tight and rain-proof.

IP65 enclosures are also well protected against tampering, just as any IP5X enclosure is.

These enclosures can also be put underground, fully or partially, if you are catering to gardening applications.

IP65 outdoor enclosure

What is the difference between IP55 and IP65?

The difference between the two enclosure types is simple.

IP55 enclosures allow some dust ingress, while IP65 are completely dust-tight.

As such, IP65 enclosures are more fit to be used outdoors in dust and sandy environments, as well as in places with lots of wind.

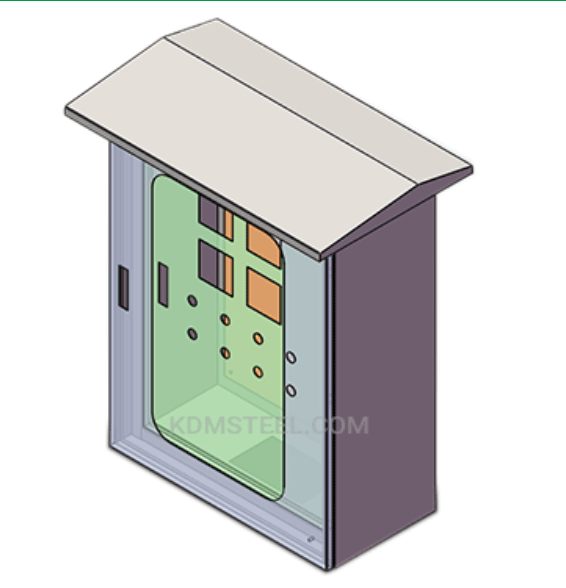

What designs of IP65 enclosures can I choose from?

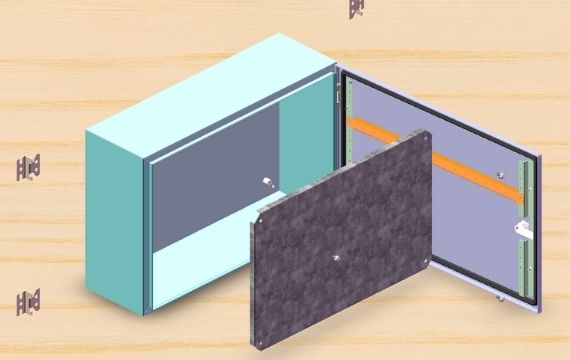

We are pleased to offer you countless designs of free-standing enclosures, wall-mounted enclosures, junction boxes, and custom enclosures.

Free-standing enclosures are perfect for large electrical units that are too heavy to be wall-mounted or pole-mounted.

They could be of any height and width.

They are also portable, and can be big enough to be categorized as walk-in enclosures.

Free-standing enclosure

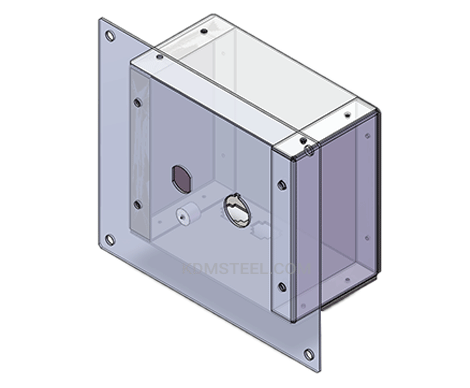

Wall-mounted enclosures use mounting brackets, screws, and pads for installation.

They are perfect for small devices in public places, as well as anywhere where space is a concern.

Wall-mounted enclosure

Junction boxes and operator interfaces are usually enclosures on a stand, but they don’t have to be.

They have user-friendly layouts, are great for small electrical units, and can be portable.

These are the most commonly used for control panels.

Junction box enclosure

Of course, we also have our custom enclosures, which can be of any design, shape, and requirements, as well as have multiple doors.

We are happy to create your perfect custom enclosure!

What features can I request for IP65 enclosures?

You can request vents, windows, hinged doors, locks, cable management systems, and much more.

Vents, as well as radiating fans, provide a path for heat to escape through, cooling electrical components of the enclosure.

This prolongs their life and decreases the possibility of malfunctions.

Radiating fan in an enclosure

These also stabilize air pressure inside the enclosure, preventing condensation which can damage the electrical components of the enclosure.

Plus, the vents can be further upgraded to air conditioners and heat exchangers.

Windows help personnel examine the electrical components in a quick and non-invasive way.

And if something goes wrong, a window helps to see what is happening right away.

Plus, infra-red windows help protect workers from arc flash accidents.

Enclosure with a window

Hinged doors control how and how much the door or cover of the enclosure opens.

This also includes a variety of handles that you can request as well.

Locks add a layer of security to your IP65 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Lock

What accessories can I request for IP65 enclosures?

Cable management systems such as cable entry frames and clamps serve to keep wires organized and make them easier to install and maintain.

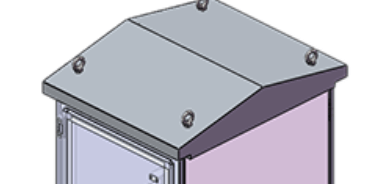

Solar shields are basically another layer on top of an enclosure that reflect solar radiation, controlling inner temperature of the enclosure to prolong the life of its electrical components.

Solar shield (the top plate)

DIN rails are used to mount circuit breakers in equipment enclosures used in industrial applications.

Rain caps are slanted roof-like top pieces that make water slide off the side of the enclosure, thus protecting it from water ingress.

IP65 enclosures benefit especially much from this feature, prolonging its life outdoors.

IP65 rain cap with lifting eyes

We also make casters, thermometers, light switches, lifting eyes, operator devices, and purpose-specific features like keypads and heat exchangers.

To learn more, feel free to contact us for more information about all the different features and accessories we offer!

We will also provide any custom features you request.

Do locks, windows, vents, and hinges lower the IP rating?

Yes, features like vents, windows, and locks do somewhat compromise the IP rating, but there are ways around it.

But KDM overcomes this difficulty, offering you some of the best enclosures for your business.

We incorporate various gaskets, PU seals, latches, and filters to balance out the IP rating.

What materials can be used for IP65 enclosures?

The materials used for IP65 enclosures aren’t different from materials used for other types of enclosures.

They can be made from carbon steel, galvanized steel, and stainless steel – usually of the grades 304, 316, or 316L.

Carbon steel is usually duller than stainless steel.

It is also magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion.

Stainless steel is created by adding chromium, nickel, and molybdenum to the iron-carbon alloy.

Stainless steel vs. galvanized steel

Steel grades 304 and 316 differ in the content of all additives.

Grade 316 is slightly stronger and resistant to saline and acidic water because of molybdenum.

But grade 304 is cheaper and more common.

Grade 316L has a lower carbon content, making it a little bit stronger.

Galvanized steel is coated with a protective layer of zinc that prevents corrosion.

We have galvanized steel enclosures, and this metal is vulnerable to salt water.

Please note that galvanized steel is more expensive and heavier than stainless steel.

Another type of steel that can be used is cold-rolled steel, which is thinner and more dense than normal steel – and thus, it is stronger.

Fiberglass is very strong, can dissipate heat, and insulates electricity, lowering the effect of interference and the possibility of shock.

It is made from glass fibers placed in plastic.

Fiberglass enclosure

Also, our windows are made from polycarbonate and ABS.

Polycarbonate is more resistant to corrosion, whereas ABS is cheaper.

IP65 enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys but can be depending on what you are going for and what are your needs.

Just like steel grades, aluminum alloys can be either of the 5052 or the 6061 series.

Aluminum vs stainless steel

Both are lightweight, but 5052 is more weldable, whereas 6061 has a higher resistance to corrosion.

Also, 6061 is more expensive.

Aluminum has a layer of oxide on top that prevents any corrosion.

This material is especially good for enclosures exposed to solvents, petrochemicals, some acids, most sulfates, and nitrates.

So, if you are looking to put IP65 enclosures in such mildly hazardous environments, aluminum is good for that.

If you would like to learn more, send in your inquiry now for a consultation!

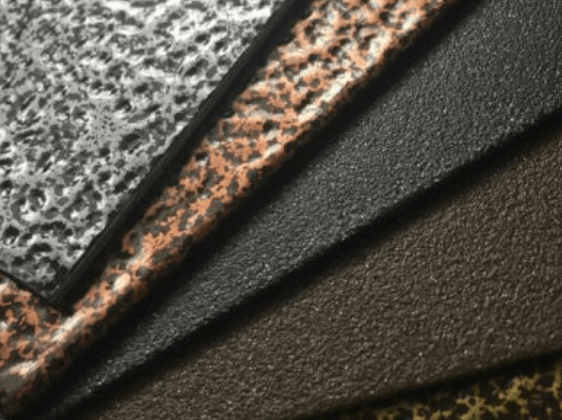

What paints and coatings can be used for IP65 enclosures?

Our enclosures are well-protected, but the right coating can add its protection as well.

You can choose enamel or powder paint coats in any color.

Enamel paint has a glossy finish and is resistant to different weather conditions.

Specific enamel paints like epoxy enamel and PU enamel are commonly used for industrial enclosures since they are resistant to corrosion.

Powder paint is deposited with the electrostatic force and is quicker and easier than enamel.

It is also more flexible in appearance, giving you the option of glossy and matte finishes.

Powder coating finishes

We also offer anodizing and alodining coatings.

Anodizing coating uses anodes to oxidize a metal, usually aluminum, to increase its thickness for better corrosion resistance.

Steel is not typically anodized because it can actually speed up the corrosion of the metal.

Alodine coating, also known as the chromate conversion coating, is used to prime steel and aluminum for paint, as well as prevent corrosion.

Alodine coating

This is a cheaper process than anodizing, and can be recognized by its characteristic greenish-yellow hue unless it is painted over.

There can also be anti-graffiti and anti-poster coatings to protect your IP65 enclosure from vandalism.

We can provide any coating in any color and finish, so contact us today!

How do you customize the symbols or writing on an IP65 enclosure?

Our customizing services include engraving and silk-screening.

Silk Screening is the easiest and most affordable method of customization.

Any flat side of the enclosure can be silk-screened with labels, warnings, serial number, your company name and logo.

However, silk-screening on metal like stainless steel or aluminum can be worn off or scratched off, but a clear powder coat helps to prevent that.

Silk screening

Engraving the enclosure is another method of customizing your enclosures.

This option is more costly and takes more time, but it is also more long-term than silk-screening.

A little bit of metal is removed from the surface of the enclosure in the design of the logo or symbol.

Usually, about 0.005 inches or 0.010 inches of metal is removed from the surface.

Once the metal has been removed, it is filled in with epoxy paint of any color to match your requirements.

Engraving

Engraving