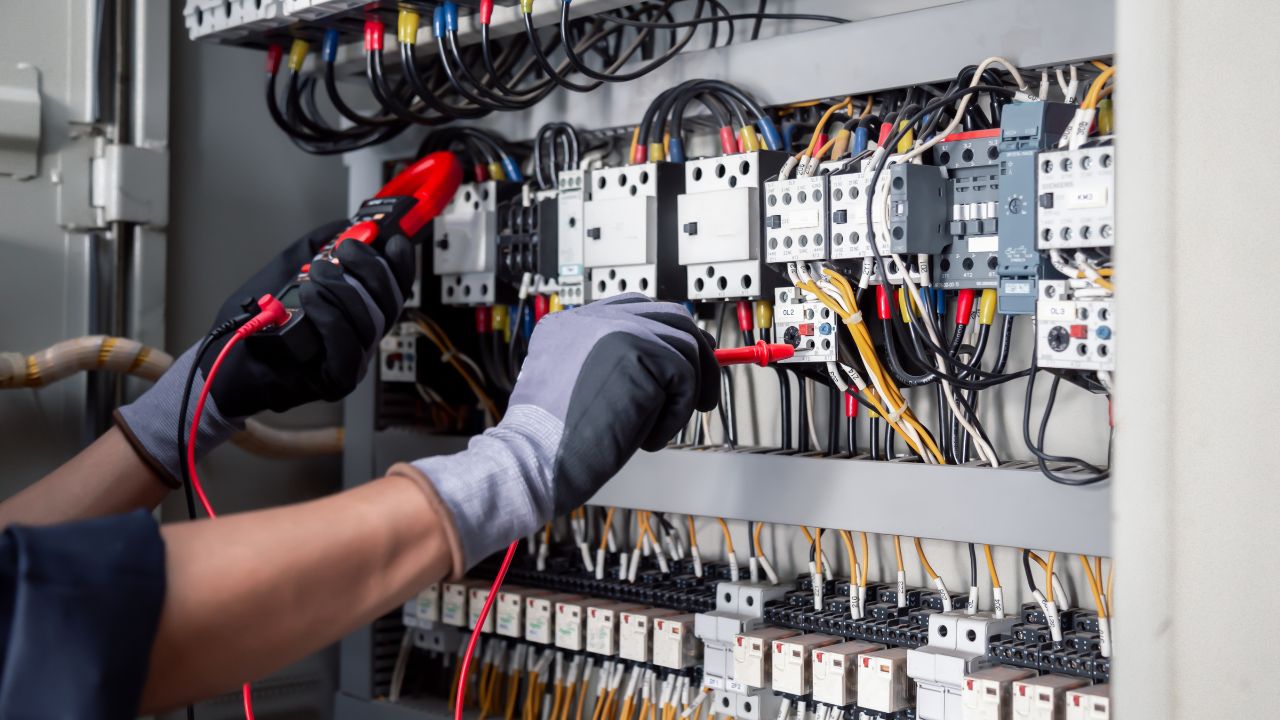

The electrical panel serves as the central hub for power distribution, and its size determines the amount of electricity that can be safely handled at one time. This article explores the common sizes of electrical panels, the factors influencing panel size, and the methods for calculating panel size. This article can help you understand the significance of electrical panel sizes and make choices that meet your current needs and long-term development.

What Does ‘Electrical Panel Size’ Mean?

The size of the electrical panel mainly includes the electrical capacity size and the physical structure size. The electrical capacity size refers to the total current that your electrical panel can safely handle, which is usually measured in amperes. The physical structure dimensions refer to the sizes of the components loaded inside your electrical panel.

The electrical capacity size determines the upper limit of your entire power system. The electrical dimensions of the panel are usually marked on the side of the main circuit breaker switch. Common values include 60amp, 100amp, 200amp, and 400amp. The physical size of the electrical panel determines how many independent circuits you can distribute power to. Generally speaking, the larger the physical size of the panel, the higher the flexibility and scalability of your system.

Common Electrical Panel Size Classification

We usually categorize the sizes of electrical panels into three types: small, medium, and large. This makes it easier for you to make a choice.

Small Electrical Panel Size

The typical size of a small electrical panel ranges from 600 amps to 100 amps. The voltage is usually 120/240 volts. The circuit breaker capacity of a small electrical panel is limited and is mainly used for lower power demands. It is mainly applied in old houses and small apartments. The size of this type of panel is obviously insufficient to support modern large power equipment and is the target for modern upgrades.

Medium Electrical Panel Size

The typical size of a medium-sized electrical panel ranges from 150 amps to 200 amps. A 200-amp electrical panel is the most common size. It can provide sufficient breaker space for most residential circuits. It also supports medium to high power loads. You can apply the medium-sized electrical panel in most modern residences. It can meet your current electrical capacity requirements and provide a certain margin for the future. It also complies with the standard residential code requirements of many regions.

Large Electrical Panel Size

The electrical dimensions of large electrical panels exceed 300 amperes, which has already surpassed the requirements of most standard residences. You can apply it to situations with extremely high power demands or for special purposes. Large electrical panels support high simultaneous power loads and allow for future large-scale expansion. It is highly suitable for electrification and smart home systems.

Standard Electrical Size Panel and Use Cases

The standard electrical panel size chart enables you to have a clear understanding of the specifications and purposes of different electrical panel sizes at a glance.

| Total Slots | Corresponding electrical panel dimensions(amp) | Physical appearance and characteristics | Use cases |

| 12-16 | 60 amp-100 amp | Small electrical box size, single row or short double row circuit breaker | Suitable for scenarios with very simple circuit requirements. Old panels are common and have fewer slots. |

| 20-30 | 100 amp-150 amp | Medium electrical box size, double row circuit breaker | There are not enough slots for today’s residential electrical panels. The application requires careful planning of the circuit or the use of double-pole circuit breakers. |

| 30-32 | 150 amp-200 amp | Standard box size, double or triple row circuit breaker | It can meet the needs of most medium-sized housing types and is a common choice in upgrade projects. |

| 40-42 | 200 amp | The mainstream full-size panel. The box is relatively wide and can accommodate three to four rows of circuit breakers. | Recommended size for new residential buildings. It can provide you with ample space for circuit distribution. Allow for the setting of a large number of dedicated or backup circuits. The layout is clear, and the security is high. |

| 54 slots and above | 225 amp-400 amp | Large wide-body box | It is used in situations where the number of circuits required is extremely high, such as the main distribution board of large residential buildings or small multi-unit properties |

Tips: The number of slots is the foundation for circuit installation. Each standard circuit breaker occupies one slot. Common electrical panel slot numbers include 12, 16, 20, 30, 40, 42, 54, etc.

Key Factors that Influence Electrical Panel Size

Total Electrical Load

The total electrical load can determine your choice of electrical panel size. The calculated total load usually includes lighting equipment, outlets, fixed appliances, special loads, and other equipment. This requires engineers to calculate the maximum load that may occur simultaneously according to NEC/IEC or local regulations. This usually uses the demand factor rather than simply adding the rated power.

Type of Building&Occupancy

The electricity consumption of different buildings varies greatly. The occupancy rules in the electrical specifications will directly affect the size of your electrical panel board. For example, residences usually have the capacity of 100 to 200 amps; commercial buildings have more load equipment and a higher total load; industrial environments are equipped with a large number of motors and machinery, so you need a larger-sized distribution board.

Voltage System&Phase Configuration

The size of your electrical panel also depends on whether you are using single-phase or three-phase electricity, as well as your voltage level. Most North American residences have a single-phase two-wire 240V/single-phase three-wire 120-240V system. Large residences or industrial sites may use three-phase electricity. The three-phase system can provide more power under the same load, thereby reducing the current capacity requirements of the distribution box.

Largest Individual Loads

In your entire circuit, the largest load can decide the panel size, such as HVAC equipment, motors, etc. The NEC code usually requires that the largest motor load be combined with other loads on the panel.

Future Expansion&Load Growth

When designing the circuit, you also need to consider the future expansion requirements of the circuit. Usually, you need to add 20-30% of future margin based on the calculated load to select the standard electrical panel size. The cost of choosing a larger panel is generally cheaper than replacing the size of the electrical panel.

Environmental&Installation Conditions

The installation environment and conditions will also affect the size of your electrical panel. For instance, component grouping, high-temperature environment or altitude can influence your size selection. Installation also needs to consider whether it is convenient for access, maintenance, and wiring. Installing indoors or outdoors will also affect the electrical panel size. Usually, outdoor panels are larger in size.

Apart from the above factors, the number of required circuits, demand factors, and code requirements also have an impact on the size of your electrical panel.

How to Calculate the Right Enclosure Size?

The accurate calculation of the size of the electrical panel is a systematic process in electrical design. Its core lies in precise load calculation, short-circuit current analysis, and strict compliance with relevant national standards. The following is a step-by-step guide to help you calculate the size.

List All Electrical Loads

First of all, you need to make a comprehensive list, including all the electrical appliances and equipment under load. You can also categorize the loads into groups such as lighting loads, general sockets, fixed appliances, motors (note the largest motor), etc. Besides clearly identifying the electrical equipment, you also need to clearly record the rated power(kW), rated current(amp), rated voltage(V), phase number, and load type of the equipment.

Apply Demand Factors

It is well known that not all electrical appliances operate simultaneously. Therefore, the total load needs to be multiplied by a demand factor. If you have motors (maximum motors) or individual large equipment, this is usually calculated at 100%. For multiple outlets and lighting circuits, the demand factor usually decreases as the number of circuits increases. The specific factor you need to refer to is the local electrical design code, such as NEC or GB 50054.

Calculate the Electrical Load

At this stage, you also need to divide the total calculated load (W) by the voltage (220V for single-phase, 380V for three-phase), and finally obtain the total calculated current (A).

That is, for the single-phase load, the total calculated current (A) = total calculated load (W) / 220 (V). For the three-phase load, you can use the formula total calculated load (A) = total calculated load (W) / (1.732 * 380). However, this formula is only applicable to three-phase balanced loads.

Determined the Main Circuit Breaker

You should choose a main circuit breaker with a rated current greater than the total calculated current. And it needs to be rounded up to the standard specifications, such as 100A, 125A, 200A, 400A, etc. Besides the current load, you also need to add a capacity margin of 10-30% for future expansion.

Calculate the Required Modulus

Apart from the electrical dimensions of the panel, you also need to guarantee the physical width of the panel. Calculating the required modulus is the key to determining the width. Standard miniature circuit breakers usually have specifications such as 1P, 1P+N, 2P, etc. Each specification corresponds to a standard width unit. If you install it in a DIN rail, one standard width can be counted as one module.

Next, you need to list all the components that need to be installed inside the panel, such as each circuit breaker, each branch circuit breaker, surge protective devices, etc. Add up the numbers of all the components. What’s more, you also need to leave some space for future expansion.

Determine the Installation Method and Dimensions of the Panel

Ultimately, you need to determine your final installation method. If you choose a concealed installation, you also need to consider the depth of the box when choosing the size of the electrical panel. For exposed installation, there are fewer size restrictions for the electrical appliances. Finally, you also need to choose the corresponding size of the panel box based on the calculated total modulus.

You should note that the width of the circuit breaker modulus may vary among different brands. Therefore, you can first determine the circuit breaker brand and then select a compatible distribution box, which can guarantee a smooth installation process.

Panel Upgrade Considerations

You need to upgrade the electrical panel when the panel ages, fails to meet national electrical standards, trips frequently, etc.. Here are the matters you should pay attention to during the panel upgrade:

Main Breaker&Feeder Conductors

If you upgrade the electrical panel, you will need a main circuit breaker of a more suitable size. A service conductor that matches the new rated current size is also necessary.

Grounding&Bonding System

When upgrading the electrical panel board, you also need to update the grounding electrode system and connection jumpers. In the sub-distribution boxes, the neutral wire also requires grounding separation.

Space, Clearance&Location Compliance

If you find that the old position does not meet the standards when upgrading the size of the electrical panel, you will need to reposition the panel. You must make sure that the operation clearance and installation height of the panel are correct and comply with the electrical standards.

Cost to Increase the Size of the Electrical Panel

When increasing the panel size, the cost of the panel itself is the lowest. The total upgrade cost may also include comprehensive upgrades of the electrical circuits, such as the replacement of the feeder, grounding upgrades, replacement of circuit breakers, and rewiring, etc.

Apart from the points you have already noted, you may also need to recalculate the load, check the short-circuit and interrupting ratings, and check circuit compatibility. If you update the public utility panel, you also need to check the capacity of the utility transformer and whether the electric meter ratings need to be upgraded, etc.

FAQ

Do IP and NEMA Ratings Affect Electrical Panel Size?

Yes. The IP and NEMA ratings will affect the size of the electrical box, but this usually refers to the physical dimensions rather than the electrical ones. Higher IP/NEMA ratings require thicker walls, door gaskets, sealed openings, and limited ventilation. This reduces the available internal space and increases heat accumulation. Therefore, for the same panel components, a larger-sized electrical panel is often needed.

How Do You Determine if Your Electrical Panel is Undersized?

If the electric panel box size is too small, it is possible that the circuit breaker trips frequently, the lights dim when the electrical appliances are started, there is no space to install new circuit breakers, and the new load cannot be added.

Is a 100 amp Electrical Panel Enough for a House?

Sometimes. A 100-ampere electrical panel size may be sufficient for a small house or apartment. However, this is only true if the house does not have a central air conditioning system and no electric vehicle chargers. For most households with a dryer, central air conditioning, and an electric water heater, a 100-amp household electrical panel is not enough.

Can You Install a Large Panel for Future Use?

Sure. You can install a larger electrical panel for future use. However, you need to be aware that the service size should match the actual load you are allowed to draw. Besides, it also needs to comply with the electrical regulations and inspection rules of your area.

Final Thought

Selecting the right electrical panel size is a critical part of designing a safe and efficient electrical system. An appropriately sized panel not only meets modern electrical requirements but also improves overall safety. KDM can provide you with high-quality electrical panels that are in line with your long-term development needs. If you have special requirements, we can also provide you with customized electrical services. We have collaborated with multiple well-known brands and obtained several certifications. Please contact us, and we will promptly respond to your needs.