As a manufacturing firm owner, if you are going to expand your business, you should know about a PLC panel. It is a modern day requirement to scale operations in your industry.

So, today you will learn about the definition of programmable logic controller panel and its important parts & types. We have also explained the advantages of PLC control panel and how you can choose the best one for your needs.

What is a PLC Control Panel?

Before introducing the PLC panel, I will tell you about the PLC. It means a programmable logic controller that works like a computer. Mainly big factory owners use this to easily control and automate their industrial operations.

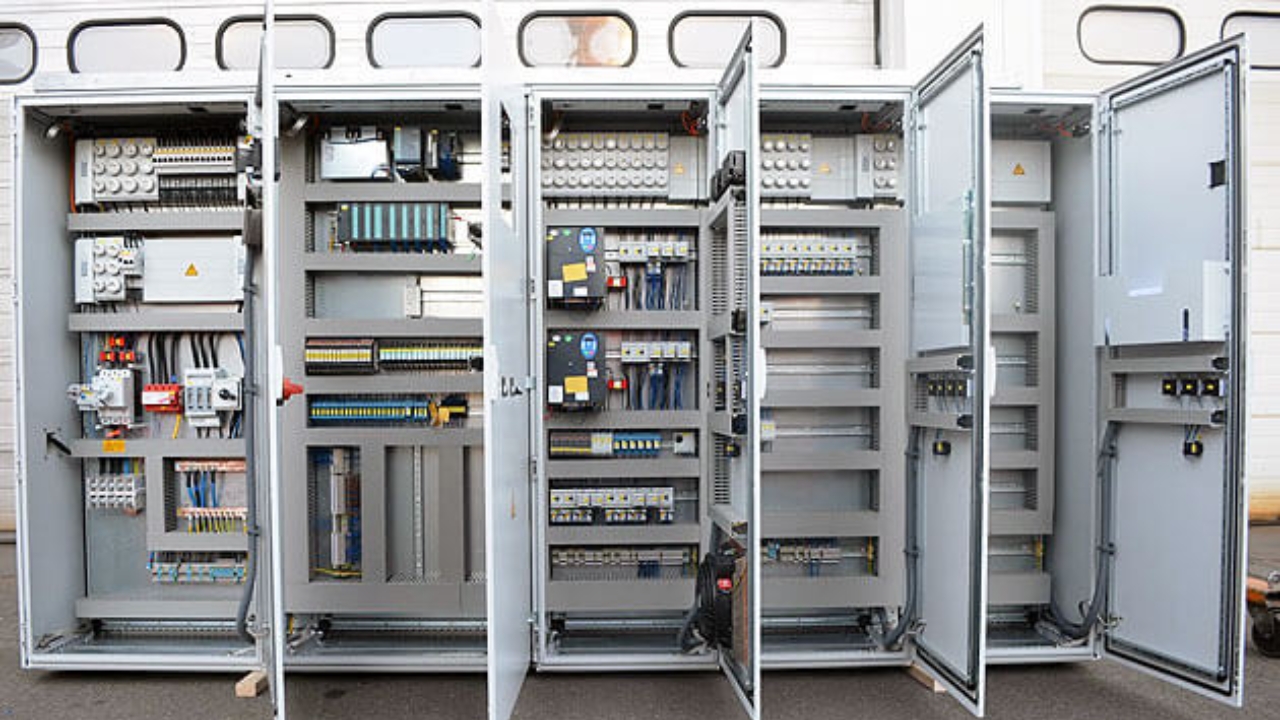

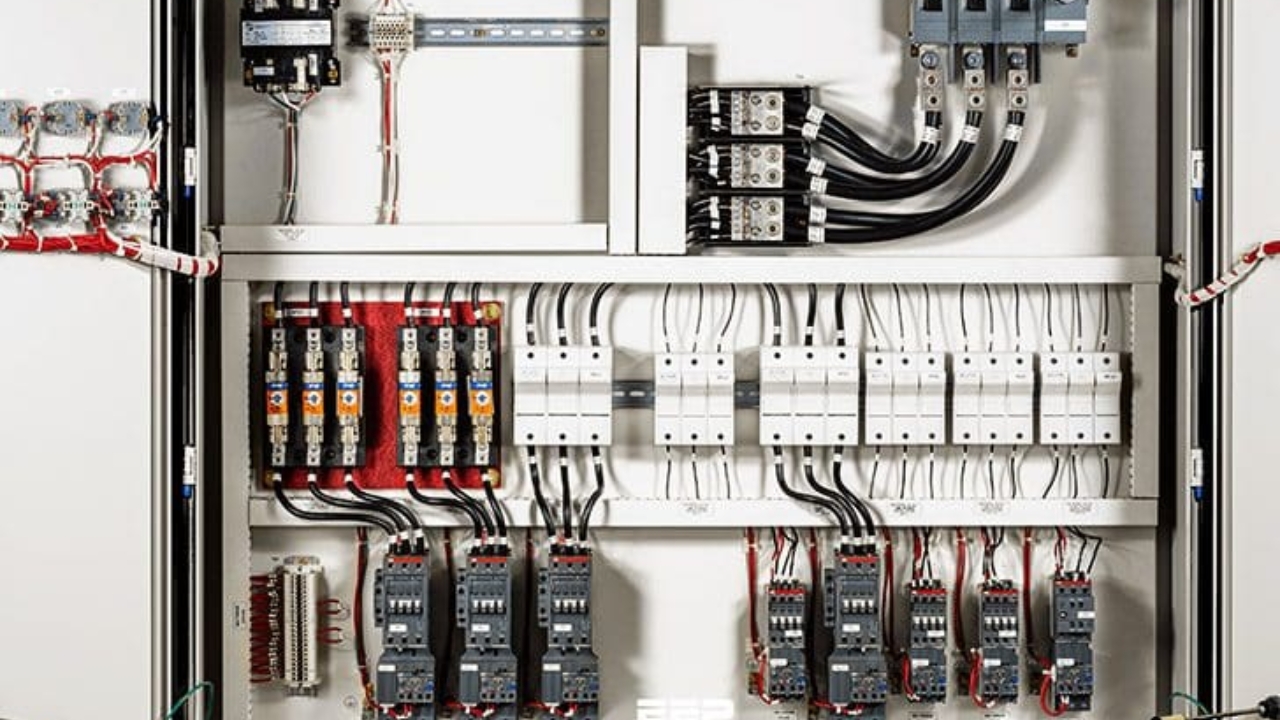

Now, we will move towards the PLC panel. This is basically a steel cabinet or box that contains PLC. The other electrical components like circuit breakers, terminal blocks, power supplies and switches are also present in this panel.

With the help of PLC electrical panel, you can easily control several electric appliances and devices in your facility.

PLC Panel Components

PLC panel consists of 2 types of components: the power and the control elements. Let’s have a look at each part of the programmable logic controller panel.

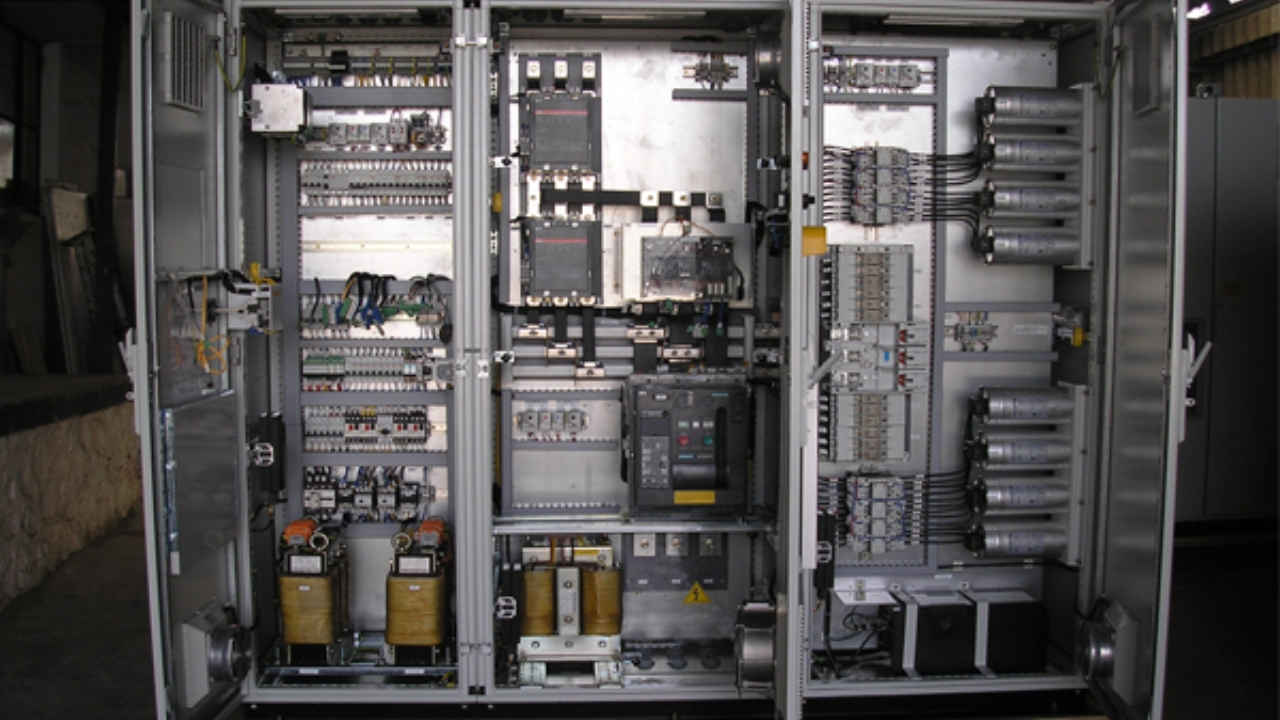

Power Elements of PLC Panel

- Power Distribution Block: Its function is to distribute power to various outputs from a single source. Therefore, a large wire is used. This brings in the main power supply which is then divided into smaller wires to distribute power.

- Transformer: It usually lowers the high voltage power to be safely used by other devices.

- Rotary Disconnect: Electricians generally use this to turn on or off the supply of power to the PLC panel. The wires that provide electrical energy to the PLC are connected to it. The power flow can be disconnected by simply rotating the dial in different directions.

- Motor Soft Starter: This device starts running the motor at low speed and then increases it gradually. This puts less pressure on the motor.

- Branch Circuit Breakers: These breakers protect other electrical devices from short circuits.

- Power Supply: The purpose of this system is to supply steady voltage to the PLC. In addition, other electrical components also get stable electrical power from this.

- Motor Starter: It is used to switch on and stop the motor safely. The motor runs with full speed and at its highest voltage level. You can also call it a contactor.

- Variable Frequency Drive (VFD): If you want to increase or decrease the speed of the motor, VFD is available for this purpose. In this way, you can monitor and adjust the speed according to your need.

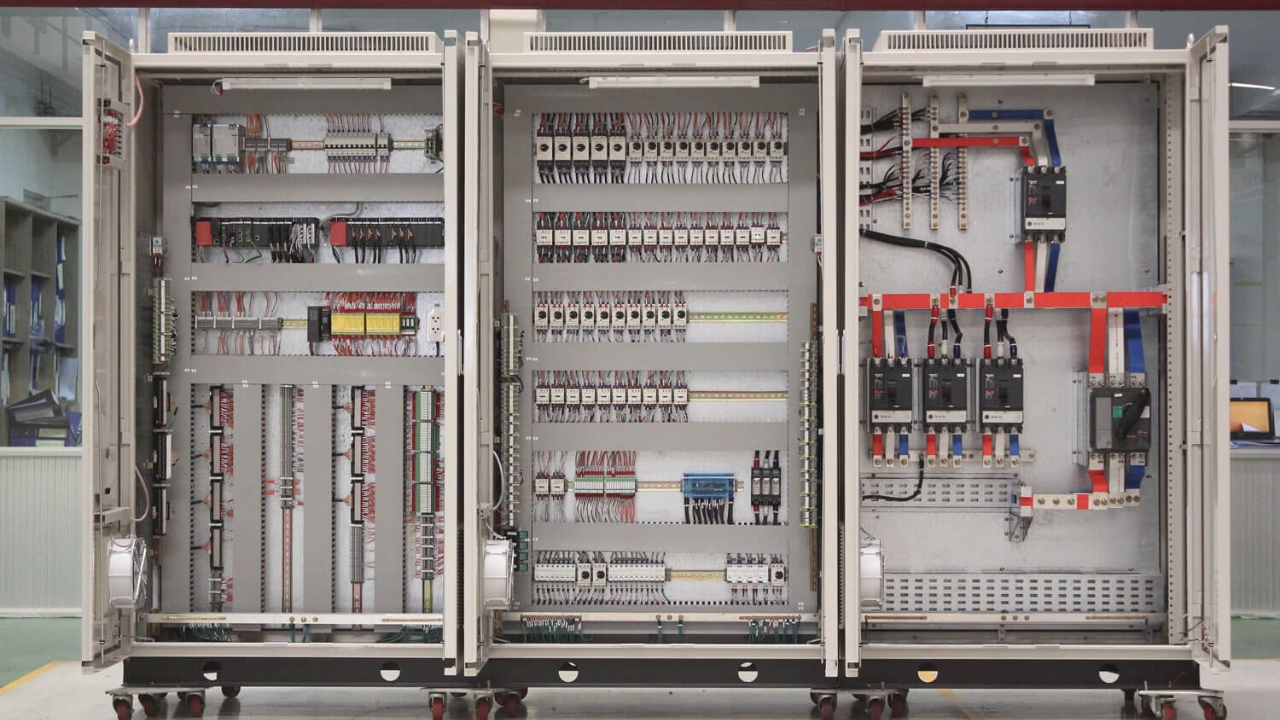

Control Parts of Programmable Logic Controller Panel

- Master Control Relay (MCR): A safety device which is generally used during emergency situations. It comes with a red button which when pressed cuts off the power supply to all the outputs.

- Human Machine Interface (HMI): By using this, you can easily monitor the real time updates from PLC. Basically, it is a display unit where you can also perform any changes to the system if needed.

- Programmable Logic Controller (PLC): It analyzes the input and performs operations according to the given data.

- Input/Output (IO) Module: The input unit provides information to the PLC, which then sends signals to the output unit to control other electrical devices.

PLC Panel Working

The PLC panel works on the basic principle of input, process and then output. This operation is also known as scan cycle. Here the input is connected to switches, pressure and temperature sensors and other electrical components.

Any change in the system is detected by the input unit, which then provides information to the PLC panel. This panel analyzes the given data and decides what to do according to the given situation.

When the decision is taken, it is sent to the output devices to perform the needed action. These devices can regulate the system temperature, increase the motor speed, lower the voltage level & perform many other adjustments.

Types of PLC Panel

Below are the types of PLC panels depending on their functionality.

Pump Control Panel

According to the water pressure in the tanks, this panel can automatically adjust the flow. It also powers up and shuts down the pump when required.

Explosion Proof Panel

Generally, you should use this panel in the conditions where there are chances of explosion. Like, the presence of flammable vapors in the atmosphere can lead to hazardous reactions. So, explosion panels are used there.

Process Control Panel

By using this PLC panel, you can monitor and access the environmental parameters accordingly. So, where there is a need for adjustments in power supply, device temperature and motor speed, the process control panel automates these adjustments.

Robot Control Panel

If you are going to use robots in your manufacturing unit, this panel controls their status. It sends signals to robots to track their working and position.

Safety Panels

At places where the use of automation is risky, safety PLC control panels are used. It offers advanced safety features with a backup system. Plus, you can also alter the system without the need for rewiring according to its usage.

For automation control panels and customized PLC electrical panels, you can see our following products.

KDM PLC Automation Control Panel

KDM PLC Electrical Panel, The Reliable Supplier in China

Benefits of Using a PLC Panel Over Other Devices

Lower Costs for Manufacturers

Once the system is developed, it will be used in multiple places without being changed. Mostly, the repetitive tasks in factories are done by a PLC panel.

This allows the same software to control all operations. In this way, only the hardware components need to be purchased.

Real-Time Monitoring

By using the PLC control panel, you can easily monitor what’s going on in the system. And then you can adjust the settings of the electrical equipment as needed.

Less Possibility of Human Error

When you use PLC panels, there are the least chances of any error. Because the data is continuously stored, monitored and is processed to give constant and accurate output.

Highly Flexible Programs

You can update the PLC panel as needed. It can be easily customized according to your requirements. You can change its wiring or introduce the new features based on your industry needs.

Precise Control

You can remotely control the panel. There is no need to be physically present there to monitor and change the settings. That means you have full control over each function of the panel.

How to Select Programmable Logic Controller Panel

Hardware Features

If you are planning to install a PLC control panel in your factory, you should be well aware of its hardware features. Because you need to select the right hardware system based on your industry requirements.

For example, in case of the memory unit, you have to choose it based on its storage capacity. And this capacity is directly related to your usage. The same applies to I/O terminals, CPU & other interfaces.

Design Type

Considering the type of design is important for the scalability of your business. You must keep in mind that the PLC panel you are going to install must be compatible with the existing electrical system.

Plus, when we talk about designs, the Expandable PLCs are easily customizable than Fixed PLCs. So, if you have future goals of your unit expansion, then expandable control panel PLCs are the best option.

Certifications

You should check that the programmable logic controller panel must be certified by standard authorities. This guarantees safety and specifies the environmental conditions in which the certified PLC control panel can operate. Below are some of the certifications:

- Conformité Européenne (CE)

- Restriction of Hazardous Substances (RoHS)

- Federal Communications Commission (FCC)

- Underwriters Laboratories (UL)

- Ingress Protection (IP)

- Atmosphères Explosibles (ATEX)

Programming Languages & Software

You have to select the language that your system can easily process. Additionally, it should be effortless for your programmers to apply changes when needed. Plus, the software system used should be editable and have troubleshooting features.

Applications of Programmable Logic Controller Panel

Power Generation Facility

Using PLC panels in power houses is necessary to regulate the environmental parameters. In addition, you can use it for power distribution and electrical grid adjustment. On the other hand, it is also utilized in water supply, treatment and sewage systems.

Entertainment Sector

In adventure parks, the movement and timing of rides are handled by programmable logic controller panels. Moreover, the sound and the lighting systems are also managed from these panels.

Manufacturing Units

The programmable logic control panels help in handling materials. It manages functions like inspection, packaging, organization and product movement to other units.

Furthermore, in order to systematize the assembly line process, PLC control panels are used here. They also handle the repetitive tasks of robotic arms in production firms.

Transit Management

PLC panels are widely used to automate the signaling in the transportation system. Moreover, the door controls in railways and buses are also done by this. It helps in controlling the vehicle’s speed on the road as well.

Conclusion

We have discussed each and every aspect of the PLC panel. Now you will be able to precisely control your machinery, equipment & enhance productivity. Additionally, with their usage, there is a minimal chance of error.

Do you want a custom PLC control panel according to your business needs? You can contact us today and tell our team your requirements. We will provide you expert guidance. We are also professional manufacturers of PLC enclosures and can supply you products at the most affordable rates.