KDM power supply enclosure delivers incredible value to your business. It is powerful and has a rigid structure where it can withstand any harsh and most demanding applications.

KDM has been in the business for over 10 years and carries a huge range of power supply enclosure products. Our outputs have been acknowledged to be one of the strong and dependable power system enclosures.

They can house all kinds of transformers and electric equipment effectively. KDM is committed to providing the highest quality standard enclosure products. So if you need an exceptional power supply enclosure and looking for a reliable supplier, try KDM now.

- Cost-effective and sturdy power supply enclosure

- Compact, high-performance range of power supply enclosure

- Quality-approved and certified products to main standards

- Professional after-sales service provided for every order

KDM Power Supply Enclosure Series

KDM manufactures an LED power supply enclosure utilizing superior-grade materials. All products are 100% assembled in our modern control room.

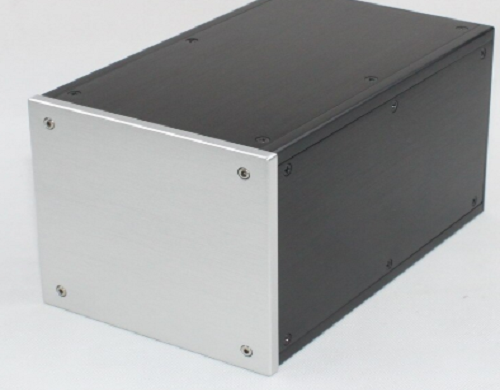

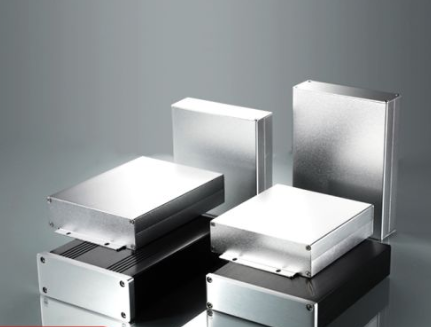

KDM gives a one-stop solution with designing aluminum chassis power supply enclosure. Save time and cost with KDM.

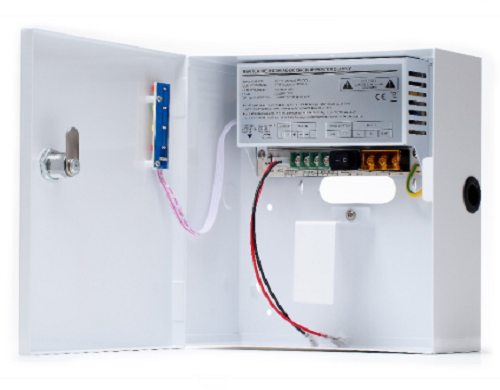

KDM 12V power supply enclosure offers a safe and effective way to secure all kinds of power systems. KDM has a wide range of products available to choose from.

KDM is your ideal solution when it comes to a universal LED power supply enclosure. With all the electric packaging needs, KDM is your first stop.

KDM can customize an aluminum vented power supply enclosure to meet the specific applications. The entire structure includes material, shapes, sizes, and types.

KDM NEMA rated 1 power supply enclosure has great protection to the environmental factors. We offered products meeting NEMA standards and IP ratings.

Send your Inquiry on KDM Power Supply Enclosure

In KDM, you will enjoy a friendly level of customer service. With a flexible structure of products, you can excellently customize ordering options. With our in-depth understanding and strong expertise in manufacturing, we are able to offer the most competitive volume of products depending on the order.

When designing with the unit, we considered all the safety regulations stated by the international and national authorities.

- High-quality power supply enclosure available at best prices

- Customized enclosure depends on system configurations

- Robust construction and extremely high-reliability cabinet

- The enclosure can be built with a removable door and lid; optional

Related Product with Power Supply Enclosure

KDM Power Supply Enclosure

We produce this product through high-grade raw material. We choose the best material when manufacturing enclosures so that the structure will be tough as it could be.

Our power supply enclosures have been designed specially to place all power equipment in a safe and reliable state. Any power supply enclosure that comes in KDM is 100% trustworthy and dependable.

Moreover, we can offer bespoke service through customizing unit structure to own specification and application. You just send your drawings with is so we could start with the production.

However, our technical team will verify first your design. At some point, they will give useful suggestions and ideas for you to have the best, innovative and unique product.

Our technical team is highly trained in all the production aspects of power supply enclosure solutions. They had the abundant insight to offer excellent service and accurate engineering support that will guide you throughout the production.

We are always prepared to work with you and give you excellent solutions. Furthermore, we also offer custom labeling the packaging of power supply enclosure products to eliminate further concern about time and labor investment.

As the leading manufacturer specializing in power supply products, we offered power supply enclosure products at an affordable rate.

Whether you need power supply products to boost your name in the market or you need it for a specific project application, you always count on quality service with KDM.

KDM engineering and technical team are certified and completely trained. With that, you can always ensure KDM capability with technical service is optimal.

Plus, with top of the line production equipment and innovative technology, we assure you quality finish product.

If you want to buy a cheaper but quality power supply enclosure, you will definitely find amazing deals from KDM.

For more information regarding our products and services, please email us. We will provide the fastest response. And deliver the most exceptional service we could to make your project efficiently.

Power Supply Enclosure: The Complete FAQ Guide

Today’s guide will help you skyrocket your power supply enclosure business.

Whether you want NEMA or IP rated power supply electrical cabinet, this guide will give you comprehensive insights.

Let’s get to it:

- How are Power Supply Enclosure different from Standard Electrical Enclosures?

- Where can you Use Power Supply Enclosure Box?

- Which Material is Power Supply Enclosure made from?

- What are the Benefits of Power Supply Enclosure?

- Is there Size Limitation for power Supply Enclosure?

- What is Cable Management in Power Supply Enclosure?

- What is Vented Enclosure Power Supply Enclosure?

- What should you Consider when Choosing Power Supply Enclosure?

- How do you Calculate Heat Dissipated by Power Supply in Electrical Enclosures?

- Is Power Supply Case the same as Power Supply Enclosure?

- What are Circuit Enclosure Boxes?

- How do you Manufacture Power Supply Enclosure?

- What are Power Supply Enclosure Standards?

- Which NEMA Rated Power Supply Enclosure is suitable for Indoor Enclosures?

- How do you Choose Power Supply Enclosure for Outdoor Enclosures?

- Are Power Supply Enclosures IP Rated?

- Why Buy Power Supply Enclosure Box with Windows?

- When should you use Large Enclosure for Power Supply?

- How can you Test the Quality of Power Supply Enclosure?

- Does Power Supply Enclosure Box have Voltage Limits?

- How do you Choose DIN Rail for Power Supply Enclosures?

- Do Power Supply Enclosures Require Heating?

- How can you Cool Power Supply Enclosure Box?

- Can you Insulate Power Supply Enclosure?

- How can you Control the Internal Temperature of Power Supply Enclosure?

- What is Power Supply Enclosure Box Safety Features?

- How does Permanent Power Supply Enclosure compare to Temporary Power Supply Enclosure?

How are Power Supply Enclosure different from Standard Electrical Enclosures?

Power supply enclosures have a unique design that distinguishes them from standard electrical enclosures.

The safety nature ensures they function and protect your application effectively.

Although they tend to resemble standard electrical enclosures, their design aims to:

i. Withstand high temperature which could be due heat dissipated by the power supply

ii. Be explosion proof to ensure safety

iii. Guarantee better heat dissipation

iv. Protect users from possible electrical shock

v. Smaller and compact in size

vi. Vents for efficient flow of air for cooling

Power supply enclosure

Standard electrical enclosure

Where can you Use Power Supply Enclosure Box?

You can use power supply electrical enclosure in virtually all areas where there is supply of electricity.

These may include electrical equipment such as computers, power distribution modules, instruments, etc.

Also, you can use them in different fields such as medical, food processing, mining, transport, entertainment, power distribution, etc.

Which Material is Power Supply Enclosure made from?

You will find different materials that are available for the fabrication of your power supply enclosure.

This is due to the unique features of these materials.

The primary materials are; aluminum, polycarbonate, fiberglass-reinforced polyester, Stainless-steel, and carbon steel.

power supply enclosure junction box

The choice of aluminum for the manufacturing of the power supply enclosure is due to its lightweight characteristics.

This has the effect of reducing the overall weight of the power supply enclosure.

Aluminum material is an ideal option for use is a harsh environment since it can withstand high impact.

It also maximizes the power supply to your application due to the prevention of electromagnetic effects.

Polycarbonate offers a non-conductive, non0magnetic material for power supply enclosure.

It is durable and lightweight for easy fabrication.

Polycarbonate based power supply enclosure is highly non-corrosive and non-reactive to different chemicals.

The ease of modification makes it an ideal material for the fabrication of different designs of your power supply enclosure

This increases its usability.

Stainless-steel and carbon-steel are a preferred option due to its durability standard and high level of chemical and corrosion resistance.

It also does not allow moisture within it, which offers a conducive environment for the proper functioning of your electrical application.

Its strength makes it ideal for the fabrication of a power supply enclosure.

The choice of material affects other factors of the power supply enclosure.

For instance, the cleaning procedure, materials such as fiberglass-reinforced polyester are delicate to clean, and you must take care when cleaning it.

What are the Benefits of Power Supply Enclosure?

Using a power supply enclosure offers the best t your application.

You gain several benefits through its use, including:

· Equipment Protection

The power supply enclosure protects your application against several external factors.

Such factors, including dust particles and water, have the effect of slowing down the operation of your application.

It also protects your electrical equipment against any damage that can affect its functionality.

· Unique Designs

Power supply enclosures have distinct designs that ensure you have the best design for your application.

Regardless of the size and type of your electrical application, you have an assurance of getting a power supply enclosure.

· Equipment Durability

Through the use of a power supply enclosure, you have a guarantee of the durability of your application.

This is because of the shielding effect that it offers to your application.

You can, therefore, use your power supply enclosure without having to worry about damages to it.

· Personal Safety

A power supply enclosure offers protection to you while operating.

Such safety helps in preventing accidents such as electrocution or mishandling of the electrical application.

· Protection Efficiency

A power supply enclosure facilitates the efficient operation of your application.

This allows you to operate your application while standing and also monitor the operation of your application.

This ensures continuous operation leading to high productivity.

Is there Size Limitation for power Supply Enclosure?

No.

Power supply enclosure does not have any size limitation.

The power supply electrical enclosure size depends on the application you are using, the design you want for your application, and the power supply requirements.

What is Cable Management in Power Supply Enclosure?

Cable management in power supply enclosure

Cable management in a power supply enclosure is the proper handling of electrical cables and wires within the power supply enclosure.

It entails fixing the right cable in the correct port and ensuring adequate sealing of unused cables.

Also, you need to check on the ratings of the cables to ensure they are of the right current load.

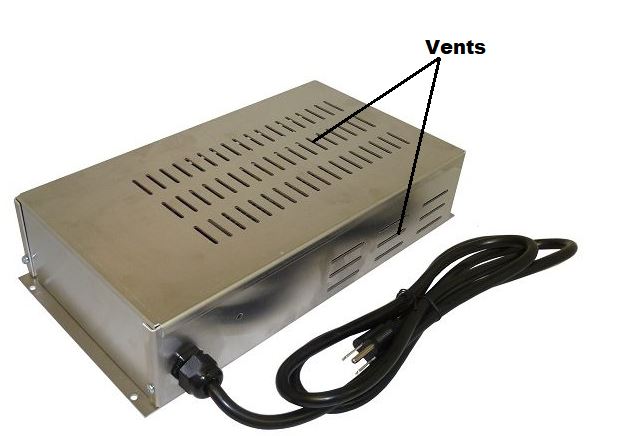

What is Vented Enclosure Power Supply Enclosure?

A vented enclosure power supply enclosure is one with proper ventilation.

It mainly uses this ventilation in the regulation of temperature.

Ventilation is a key feature in power supply enclosure since it help in cooling components.

Furthermore, this ensures an increased service lifespan of your electrical power supply systems.

Ventilation system in power supply enclosure

What should you Consider when Choosing Power Supply Enclosure?

Selecting a power supply enclosure from the varieties available in the market can be a challenge.

However, there are vital considerations that you have to check for you to purchase the right one for your application.

Such considerations include:

· Size of your Power Supply Enclosure

The different sizes and designs of your power supply enclosure are for fitting the various applications.

You have to select the perfect size and design that fits your application.

Remember, you must check on the space available.

This helps in ensuring proper ventilation and temperature control during the operation.

It is also essential in easy access to the different components of the power supply enclosure during maintenance.

· Type of Power Supply Enclosure

There are two main types of power supply enclosure available in the market, that is, outdoor and indoor power supply enclosure.

Each of these types has the features that make them suitable for their use.

You need to consider your application for you to select either the indoor or outdoor power supply enclosure to use.

· Voltage Ratings

Different applications have different voltage ratings, which makes them operate effectively.

The correct power supply enclosure should correspond to the voltage requirements of your application.

· Material

Different materials are available for the manufacturing of power supply enclosure.

Such materials include aluminum, carbon steel, and fiberglass.

Each of these materials has unique features that make them ideal for their use.

The material that you select should be highly resistant to elements such as corrosion and offer better thermal insulative properties.

· Performance Standards

An effective power supply enclosure should offer quality service while minimizing the maintenance cost.

Purchasing it from a reliable manufacturer ensures you have quality service for your operation.

A power supply enclosure with all the necessary ratings implies that it certifies all the quality standards available.

This means it has high-performance standards.

· Environmental Conditions

The operating environmental conditions will determine which power supply enclosure to select.

These conditions include the ventilation, temperature, and humidity.

The conditions affect the operation of the power supply enclosure.

How do you Calculate Heat Dissipated by Power Supply in Electrical Enclosures?

Calculating the heat dissipation of your power dissipation helps in determining the best environment for its operation.

This environment includes getting the right ventilation or temperature regulation method.

The calculation procedure involves first determining the heat generated within the power supply enclosure through the power input.

This should be in watts.

Then, you calculate exterior heat transfer.

You can achieve this by determining the exposed area to air in square feet.

While doing this, avoid the top surface of the power supply enclosure.

Calculate the differential temperature between the optimum surrounding temperature and the internal temperature.

Using a temperature conversion table, you can now determine the Btu/hr./ft.2 for the differential.

Get the product of the differential and the power supply enclosure’s surface area.

You can get then heat dissipation for your power supply electrical enclosure by adding the external and internal heat loads.

Power supply enclosure

Is Power Supply Case the same as Power Supply Enclosure?

Yes.

They are the same.

They have the same design and function.

However, they differ in the area of application.

The power supply case is mainly for minor applications, especially in households.

Power supply enclosure is bigger in size and is of use in high current demanding applications.

What are Circuit Enclosure Boxes?

These refer to boxes that are for mounting electrical components such as knobs and switches.

They can either be of stainless steel, aluminum, polycarbonate, or fiberglass.

They facilitate the display and ease of accessibility of the electrical equipment.

They are also vital in preventing electrical shock both to the operators and the electrical equipment.

How do you Manufacture Power Supply Enclosure?

The manufacturing process of a power supply enclosure entails several simple stages.

These stages ensure you get the best power supply enclosure for your use.

Power Supply Enclosure Laser Cutting

This process involves cutting the different parts of the power supply enclosure using a laser machine.

The use of a laser machine is encouraged for accurate cutting of these parts.

It also prevents scratching and blurring of the power supply enclosure.

Power Supply Enclosure Welding

Welding involves the use of a welding machine to join parts of a power supply enclosure.

The welding process should be in line with the set standards.

Proper welding should ensure there is no interference between the enclosure and the external environment.

It also reinforces the sides of the power supply enclosure.

Power Supply Enclosure Bending

Bending ensures accurate design offering a smooth surface that does not have any unnecessary bends.

There is a need for ensuring proper bending as per the measurement of the power supply enclosure design.

Power Supply Enclosure Polishing

Polishing offers a clean and aesthetic appeal for your power supply enclosure Polishing.

Giving it a fresh paint while working on the surface smoothness makes it have an attractive appearance.

Power Supply Enclosure Assembly

The assembling process involves tightening the different parts of the power supply enclosure using screws and nuts.

This way, the power supply enclosure functions as a unit

Testing and Approving

You have to test and certify your power supply enclosure before using it.

Such a test determines the environmental conditions necessary for optimum functionality.

What are Power Supply Enclosure Standards?

The quality of a power supply enclosure is vital in ensuring its proper functioning.

That is why, before releasing to the market, it has to meet several standards.

Some of these standards are international standards, while others depend on the region of their manufacturing.

The common standards for a power supply enclosure are:

Power supply enclosure

· RoHS

RoHS prevents the use of hazardous materials in the manufacturing of power supply enclosures.

It helps in ensuring that the power supply enclosure is environmentally friendly and that its use does not emit poisonous substances.

Hazardous materials include mercury, lead, chromium, and polybrominated diphenyl ethers.

· NEMA

NEMA’s regulation is mean for the electrical and electronics industry.

As a global organization, its task is to ensure the safety of these products for their intended use.

There are thirteen categories of NEMA standards that a given power supply enclosure should adhere to before its release in the market.

Each of these categories offers a specific standard in ensuring the quality of your power supply enclosure.

For instance, you can have a NEMA standard that describes the quality of a power supply enclosure in offering protection against dust and water.

Yet another can protect against personal access of the enclosure to hazardous parts.

· IP ratings

The primary purpose of IP ratings is to check on the standards that the power supply enclosure has to offer against water and solid intrusion.

It is usually a two-part standard in which one part describes the level of protection against solid particles.

The other part describes the level of protection against water intrusion.

You must check your power supply enclosure to ensure that it can effectively prevent water and solid particles.

If such particles get into contact with your electrical components, then they can lead to malfunctioning.

You should select a power supply enclosure with an IP rating of 5 and above.

· UL

This is a global standard that assesses the quality of a given power supply enclosure to ensure it meets the standards necessary for the market.

In some countries such as the US, your power supply enclosure must have this standard

Which NEMA Rated Power Supply Enclosure is suitable for Indoor Enclosures?

The safety features and the design of NEMA rated power supply enclosures make them suitable for use in indoor enclosures.

These safety features include ventilation and insulation mechanism.

NEMA rated power supply enclosure does not emit hazardous products, which can pose a danger to the environment and people.

Depending on the prevailing conditions, nearly all NEMA power supply enclosures are good for indoor use.

NEMA power supply enclosure

How do you Choose Power Supply Enclosure for Outdoor Enclosures?

You need to be keen when selecting a power supply enclosure for your outdoor applications.

This is because of the different outdoor needs and the different types of enclosures available.

Among the factors to check to include:

· Environmental Conditions

The environment that your power supply enclosure will operate in determines the type of outdoor enclosure to select.

Factors to consider in an environment include the humidity, the external temperature, and the pressure level.

An active outdoor power enclosure should be resistant to external environmental conditions such as dust and humidity. It should also provide adequate thermal insulation.

· NEMA ratings

NEMA ratings explain the protection level that your outdoor power supply enclosure offers against dust and humidity ingression.

They help in determining which outdoor enclosure to use based on the operating environment.

Dust and humidity have the effect of slowing down the operation of the enclosure.

The common NEMA rating is Type 3R, 3RX, type 4, 4X, and type 6, 6P.

· IP codes

The IP code is a two-part labeling series that describe the protection a particular outdoor enclosure offers.

It protects the enclosure against elements such as dirt and water.

The first part of the series describes the level of protection against dust and solid particles.

The second part identifies the degree of protection of the enclosure against liquids.

Whichever the outdoor power supply enclosure you select, it should have the right IP codes depending on the environment it will operate in.

· Security Features

Given the sensitivity of the outdoor power supply enclosure, the security features should determine which one to select.

Security features include the secure laying of the cables and non-interference with the outdoor enclosure.

· Thermal Management

Remember, an outdoor power supply enclosure is subject to interference with the external temperature changes.

You, therefore, have to select an outdoor enclosure that has proper thermal management.

Such an enclosure should have a proper insulation mechanism.

This helps it in maintaining a constant operating temperature, which is essential for the continuous operation of your application.

Are Power Supply Enclosures IP Rated?

Yes.

Quality and sufficient power supply enclosure should be IP rated.

This helps in protecting the power supply enclosure against several undesired factors.

These factors include water intrusion, accidental contact, and dust particles.

IP ratings help in the efficient operation of your power supply enclosure.

It also helps in reducing the need for maintenance, which saves costs in the long run.

Why Buy Power Supply Enclosure Box with Windows?

Power supply enclosures that have windows help in the ventilation process.

This is vital in ensuring that proper temperature control within the power supply enclosure.

Windows are also helpful in facilitating access to the components within the power supply enclosure.

When should you use Large Enclosure for Power Supply?

The use of a large enclosure is common in applications that utilize a large current.

The size of such a power supply necessitates the use of a large enclosure.

How can you Test the Quality of Power Supply Enclosure?

Getting a quality power supply is essential for ensuring quality service for your application.

For that to happen, you have to test several aspects of the power supply enclosure.

Power supply enclosure

The critical tests are:

· Temperature Rise Limits

This test determines the durability and reliability of the power supply enclosure.

Excessive temperature causes premature aging of the enclosure’s components resulting in its failure.

Carrying out this test helps the manufacturer to select the ideal option for your power supply enclosure.

You can conduct a temperature rise on the individual components of the power supply enclosure.

· Dielectric Property Test

The dielectric property test determines the insulation performance levels of the power supply enclosure.

This helps in determining its maximum operating voltage.

For this test, you use an industrial frequency of 50Hz, which is in the form of the voltage waves.

These waves stimulate a lightning strike.

· Short-circuit Resistance

The purpose of this test is to determine the resistance of the power supply enclosure to electrodynamic and thermal stress.

· Effectiveness of the Protective Circuit

You need to carry out this test as per the standard IEC 61439-1 using a test current that is 25A.

You need to carry this test between the exposed conductive components and the protective conductors.

You can also conduct this test at the point of high fault current, which can occur when there is an accidental detachment of the conductor.

· Clearances and Creepage Distances

This test determines the creepage distance as well as the clearance as per IEC standards.

For this, you measure the distance between the live parts with varying polarities.

You also need to measure the distance between the exposed parts and the vital parts.

· Mechanical Operation

You conduct this test on the components that don’t have any specific requirements.

You determine this by analyzing 50 operating cycle on the drawback of the power supply enclosure.

· Degree of Protection (IP)

You can conduct this test in accordance to the IP rating guidelines.

This test determines the level of prevention of dirty entry to your power supply enclosure.

Does Power Supply Enclosure Box have Voltage Limits?

Yes. Most power supply enclosure has a voltage limit.

The voltage limit allows for accurate and safe handling of power supply to your application.

This helps in minimizing excess power supply, which can harm your application.

There are three categories of power supply enclosure – low-voltage, medium voltage, and high voltage.

The low voltage power enclosure handles a power supply of up to 600V.

The medium voltage power supply enclosure offers a power supply of between 600V and 69kV.

A High Voltage power supply enclosure controls the power supply of between 69kV and 230kV.

How do you Choose DIN Rail for Power Supply Enclosures?

Choosing a DIN rail can be a challenge, especially if you have a unique design.

However, by following these considerations, you can accurately select one for your use.

· Mechanical Style Dimension

There are three types of DIN designs, that is, Top hat design, the G-section, and the C-section design.

The Tophat design adheres to BS 5584, DIN 4677-3, and EN 5002 regulations.

Top hat design is available with either 15mm depth or 7.5 mm depth.

You can also have miniature Top har designs for your application.

These designs are 15mm in height.

The G-section adheres to the BS 5825, DIN 46277-1 and EN 50035 standards.

The C-section can either be C20, C50, C30 or C40.

The number suffix on the types is the height of the rails measured in mm.

You must check on the compatibility of the design of your DIN and the power supply enclosure.

· Cooling Methods and the Operating Temperature Range

You have to check on the different operating temperatures and the cooling methods that a given power supply offers.

This should factor in the DIN rail installation procedure.

Ideally, your power supply enclosure should not have external fans, or it should not use forced air cooling.

This can pose a challenge when setting up your power supply enclosure.

The operating temperature should not affect the physical property of the DIN rail.

· Protection Types

There ought to be no interruption in the operation of the DIN rail.

You need to ensure that there is a secure power supply to the DIN rail such that it offers continuity to its operation.

You also need to specify the DIN power supplies which protect against overload, short circuit, and overvoltage.

· Connection and Wiring

The type of connection that your power supply enclosure uses determines the kind of DIN rail you select.

There should be no adverse effect between the operation of your DIN rail and that of the power supply enclosure.

Do Power Supply Enclosures Require Heating?

Yes.

Heating is an essential consideration for the effective working of your power supply enclosure.

Lower temperature hurts the components of your power supply enclosure, affecting its operation.

For instance, rubber in low temperatures makes them lose flexibility affecting the tightening ad sealing of the power supply enclosure glands.

Plastic has the effect of becoming brittle at low temperatures, which reduces their flexibility.

In low temperatures, plastic builds up static energy, which is dangerous to the environment, especially in a hazardous environment.

Metal parts lose their flexibility, and they become brittle.

This affects their ability to withstand explosive pressure and high impact.

However, you need to take care when heating your power supply enclosure.

This is because too much heat also reduces its effectiveness.

The main methods of heating your power supply enclosure are:

· Explosion-proof Heaters

They use the traditional way to heat your power supply enclosure.

That is, cold air circulates the heater’s body, which raises its temperature.

As the air warms up, it becomes light causing it to rise and circulate within the power supply enclosure.

The process continues to make sure the power supply enclosure maintains the right temperature for its use.

These are the only heaters that you can comfortably use in a hazardous environment.

· Fan Heaters

They are the simplest form of heating your power supply enclosures.

It involves the passing of electrical current through the heating element, which creates heat.

As this happens, air from within the enclosure flows into the heating element using the fan.

It is this heat that warms up the air which circulates within the enclosure, thereby raising its temperature.

· PTC Heaters

PTC (Positive temperature coefficient) use specialize in conductive materials.

The working of this heater is that it allows for current to pass through when the enclosure gets cold.

However, when the temperature starts increasing, the material begins inhibiting the current flow.

That is temperature increase results in an increase in the increase of the electrical resistance of the material.

This has the effect of limiting the current flow.

It is an effective method since it does not cause overheating of your power supply enclosure.

How can you Cool Power Supply Enclosure Box?

While it is crucial to heat your power supply enclosure, cooling it is also vital.

This is because for it to operate effectively, there is a need for it to be at an optimum temperature.

For instance, too much heat on the plastic material causes it to melt, exposing the vital parts of your power supply enclosure.

This is dangerous for its continuous operation.

The main cooling methods that you can use for your power supply enclosure include:

Conduction cooled power supply enclosure

· Natural Convection Ventilation

Natural convection ventilation utilizes heat transfer from the warmer regions to colder regions within your power supply enclosure.

This only takes place when the outside environment of your power supply enclosure is colder than the inside.

In this way, heat radiates from the enclosure through the walls to the outside environment.

As this happens, the internal temperature reduces to a level that is equal to that of the external environment.

Natural convection ventilation is a less costly and straightforward option for your power supply enclosure.

However, it is less effective since it is dependent on the temperature of the external environment.

This implies if the external temperature is higher, the power supply enclosure will not cool.

If this happens, there is a compromise on the efficiency of the performance of your power supply enclosure.

· Forced Convection Ventilation

Forced convection ventilation uses a fan or blower to force warm air out of your power supply enclosure.

It is important to note that whichever blower or fan you use, it should include a filter.

Remember, air flowing from the outside to the inside may have contaminants such as dust and dirt.

When these contaminants get in contact with the electrical components of your power supply enclosure, malfunctioning occurs.

A filter is, therefore, a vital component in filtering the air flowing into the power supply enclosure.

This method is relatively affordable and easy to install.

You can also control the volume of air flowing into the enclosure by adjusting the speed of the fan or blower.

However, it requires regular maintenance to remove the contaminants present in the fan or blower.

If this does not happen, dirt will accumulate on the blower or fan, which may hinder its proper functioning.

This causes dirt to enter into the electrical components.

Can you Insulate Power Supply Enclosure?

Yes.

You can insulate your power supply enclosure.

Insulation plays a critical role in providing the optimum operating temperature for your power supply enclosure.

Useful insulation material should be resistive to normal heat, resistive to abnormal fire, and fire.

It should also offer thermal stability and be resistant to ultraviolet radiation for the case of outside power supply enclosure.

The best insulation material that you can use for your power supply enclosure is polyurethane and polyisocyanurate foam.

Polyisocyanurate foam is a combination of polyol and isocyanurate using a catalyst.

The resulting polyisocyanurate is a cellular thermoset.

It is an ideal material due to the features of the individual components which have closed cells.

These cells form a fire-retardant structure.

The generally inert, highly stable material offers the highest weight to strength ratio and a superior thermal insulating material.

Polyurethane is a rigid and offers high-performance material for insulating power supply enclosure.

The high cross-linked property of the polyurethane that is of low density.

The low thermal conductivity of the blowing agents present in the polyurethane is what makes them the best insulating material.

How can you Control the Internal Temperature of Power Supply Enclosure?

Control of the internal temperature of your power supply depends on several factors.

For instance, the insulation method, which determines the efficiency of the enclosure towards minimizing heat loss.

Insulation helps in protecting the power supply enclosure from losing too much heat, which affects its operation.

Ventilation is also a critical factor in regulating the temperature of your power supply enclosure.

It does this by minimizing the temperature of the power supply enclosure when the temperature is high.

What is Power Supply Enclosure Box Safety Features?

Power supply enclosure safety features offer protection in its handling and maintenance procedures.

The primary safety features available on the power supply enclosure are the safety signs possible on its box.

Such signs include the handling procedure, the danger signs, and the warning signs.

How does Permanent Power Supply Enclosure compare to Temporary Power Supply Enclosure?

The installation of a permanent power supply takes into consideration the fixed installation process.

This means it can quickly move.

For a temporary power supply enclosure, it takes into account its flexibility feature; hence its installation process is quite easy and to install.

Clearly, choosing a power supply electrical enclosure involves evaluating a range of aspects.

You should evaluate type of material, quality compliance, cooling system, to heating accessories.

All these are covered in this guide.

However, if you need a custom power supply enclosure, our team is here to help – Contact us now.