Your Reliable High Voltage Switchgear Manufacturer?

KDM has over 10 years High Voltage Switchgear manufacturing experience in China

Premier High Voltage Switchgear Supplier in China

KDM is one of the leading China High Voltage Switchgear manufacturers and Suppliers. We offered a full range of main products in order to meet various customers’ requirements. High voltage switchgear such as control boxes, insulators, and others. All our products meet and exceed the main testing. Therefore, you can ensure that each of our high voltage switchgear products is safe and reliable.

High Voltage Switchgear offered by KDM can be customized. For any bespoke solutions, you can rely on us. As we have an expert team of engineers and designers that are able to develop products according to your specifications. Before customization starts, first, you need to send us your drawing or give us your idea. Then our engineers will check your design. Our range of high voltage switchgear products can be fitted into various electric system applications.

Send Inquiry Now.

KDM High Voltage Switchgear Series

Are you looking for a high-quality indoor high voltage vacuum circuit breaker? KDM has a wide array of this excellent products, used to protect and control the elements from electronic equipment.

KDM VMD5 high voltage vacuum switchgear is useful in wider applications in different fields and environments. High reliability and safety of the electric system are achievable. KDM is the place of reliable and trusted high voltage vacuum switchgear.

State-of-the-art high voltage vacuum switchgear for electricity is what KDM is dedicated to presenting to you. Whether you need this for some company requirements or special projects, we have a solution right for you.

Our three-phase AC high voltage switchgear has been tested with the requirements of the National Standards and International Standards. Our product range allows you to find the perfect selection according to your needs.

If you are looking for high performance, trustworthy and flexible vacuum high tension voltage switchgear, KDM is your ideal supplier. This product has special, excellent features for safe and reliable operation.

Our Outdoor-type High Voltage Switchgear offers outstanding reliability, mechanical robustness, and a long-lasting electrical life span. This is the perfect solution for all your electrical network needs. Require limited maintenance and cost-efficient outdoor-type high voltage switchgear attainable in KDM.

Send your Inquiry on KDM High Voltage Switchgear

At some point, they will give some piece of advice, suggestions to make your proposal more competitive. To finalize the proposal, they will send you a sample layout to get your approval. After everything, they will start with the production. Detailed and efficient production services are a must at KDM.

- Quality is fully tested like mechanical tests, temperature-rise tests, power frequency voltage tests, and more.

- Professional and Zealous Technical Engineers design Highest Quality High Voltage Switchgear

- Reliable and Functional Products fitted to the various electric system application

- Completely controlled by the highest ISO 9001 standards

Related Products of High Voltage Switchgear

KDM High Voltage Switchgear

Our high voltage switchgear is manufactured from our modern production unit. It is processed through different mechanism techniques. The development and manufacturing are excellent that enable to produce high quality high voltage switchgear products. Our facility equipped with the latest tooling components that will surely use to come up with the product within lead time. Furthermore, professional technical engineers allow orders to flawlessly design and developed. These employees make sure the outcome is in outstanding quality form.

These high voltage switchgears meet and exceed industry quality standards. They have been fully tested like a mechanical test, temperature-rise tests, power frequency voltage tests, and more. Our controllers carry out many diverse tests to assure its stability, reliability, and functionality. In KDM, we make sure all our products fully comply with international standards. Whether you need high voltage switchgear for power transmission, distribution equipment or any other projects, we assure you find and get best deals with us.

As an ISO 9001 certified High Voltage Switchgear factory, we design and manufacture products from finest quality raw material. As a certified quality management system, you can guarantee highest quality high voltage switchgear products at a competitive cost. Over 10 years of manufacturing experience, we are able to provide optimum solutions for every requirement’s sent on us. Our customer-friendly sales team can assist you with all the processes and operations. With KDM, you can find the best value of your money with in terms of quality production.

In KDM, you can find the best solution for your specific requirements. We have equipped with team of highly experienced and zealous professionals that will manage your request. Over the last 10 years, KDM is continuously upgrading product. In order to meet the necessary standards, fully aim orders sent upon us, we are engaged to produce highly innovative products. KDM is your one-stop-shop solution for all your high voltage switchgear needs.

For your request, feel free to contact us. We have 24/7 online support available.

High Voltage Switchgear: The Ultimate FAQ Guide

- What is High Voltage Switchgear?

- What is the Function of High Voltage Switchgear?

- How does High Voltage Switchgear compare to Low Voltage Switchgear?

- Where can you use High Voltage Switchgear?

- What are the Advantages of High Voltage Switchgear?

- How do you Specify High Voltage Switchgear?

- What are the Main Components of High Voltage Switchgear?

- How does High Voltage Switchgear Work?

- What is the difference between High Voltage Switchgear and High Voltage Switchboard?

- How does High Voltage Switchgear and Control Gear Compare?

- What is the Voltage Range for High Voltage Switchgear?

- How can you Test High Voltage Switchgear?

- What are the Types of High Voltage Switchgears available?

- How does Gas Insulated High Voltage Switchgear compare to Air Insulated High Voltage Switchgear?

- What is the difference between Dead and Live Tank Type Circuit Breaker?

- What are the Features of High Voltage Switchgear?

- How do you Troubleshoot High Voltage Switchgear?

- How do you Maintain High Voltage Switchgear?

- Is there a Difference between Current Interrupter and Switchgear?

What is High Voltage Switchgear?

A High voltage Switchgear is a type of switchgear that has special features that enables it to handle power systems of higher than 36kV.

High voltage switchgear

What is the Function of High Voltage Switchgear?

The function of High Voltage Switchgear includes:

- Isolation of electrical circuits from the main power source, which helps in safe clearance of electrical faults and general maintenance.

- It has devices that help in the distribution and controlling of electric current.

- Connection and disconnection of electric induction motors

- Performing quantitative and qualitative power supply measurements.

- It has devices that offer protection against overloading and short circuits.

- This helps in ensuring the safety and functionality of the electrical equipment.

How does High Voltage Switchgear compare to Low Voltage Switchgear?

Low voltage switchgear

High Voltage Switchgear handles a power system that has a voltage rating of above 36kV.

Low voltage switchgear handles the power system with a voltage rating of below 1kV.

Where can you use High Voltage Switchgear?

You can use a High Voltage Switchgear in the following areas:

- Wind turbines

- Electrical Motors

- Generators

- Solar power generation

- Residential power distribution

- Power supply systems.

- Environmentally sensitive installation

- Underground stations.

- It is common in industrial applications such as in the steel, paper, and mining industry.

- Marine applications

What are the Advantages of High Voltage Switchgear?

The advantages of High Voltage Switchgear include:

HV Switchgear

· Reliability

High Voltage Switchgear offers a reliable option for your normal power use.

This switchgear has mechanisms that identify faults and enable quick fixation of these faults.

You, therefore, have a reliable power source for your consumption.

· Ease of Assembling

High Voltage switchgear is easy to assemble. It requires a few expertise to assemble this equipment in addition to reading the manufacturer’s manual.

· Protection

A high Voltage Switchgear offers protection to live electrical conductors which ensures the safety of your electrical application.

· Cost

The cost of purchasing and maintaining High Voltage switchgear is lower than the cost of not using one.

A High Voltage Switchgear offers protection to your electrical equipment without which damaged your equipment would be high.

· Ease of Maintenance

Components of High voltage Switchgear are easily accessible hence allows for quick maintenance in case of occurrence of electrical fault.

How do you Specify High Voltage Switchgear?

You need to specify the voltage requirements for your electrical equipment if you want to specify HV switchgear.

What are the Main Components of High Voltage Switchgear?

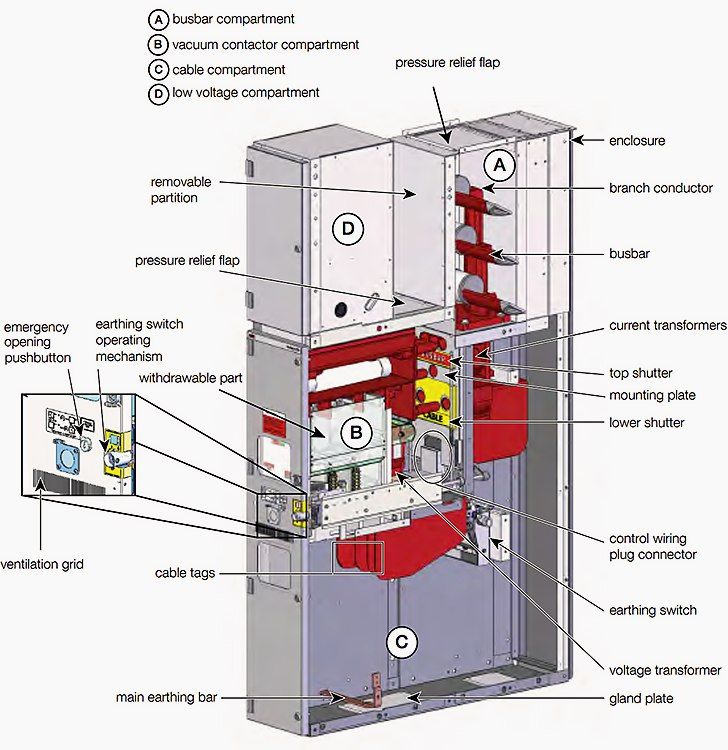

The main components of a High Voltage Switchgear are:

Parts of high voltage switchgear – Photo couhttps: SISAMBEN

- A surge arrestor: The function of these components is to disperse excess voltage within the High Voltage switchgear to the ground. This helps the system to function appropriately.

- Step-down transformer helps in the conversion of voltage from high to low, which the High Voltage switchgear can use.

- Instrument transformers: Their function is to measure the electrical parameters necessary to protect the High Voltage switchgear.

- Earthing Switch:Earthing switch helps in directing excess electrical current in the switchgear to the ground. This helps in reducing electrical overload and the occurrence of electrical faults.

- Busbar: A busbar acts as a connector for various lines distributing power to different sections of the High Voltage switchgear.

- Air break switches: They help in the sustenance of two lines or equipment of the High Voltage Switchgear, thus minimizing electrocution. This is through isolation of circuit and equipment within the switchgear.

- Circuit breaker protects the electrical circuit whose source has an overload. They also help in fault interference during a repair.

- The voltage regulator helps in ensuring the High Voltage switchgear uses the right voltage during operation.

- Metal clad: This is the nerve center for distribution lines leaving the High Voltage switchgear. It helps in the isolation of lines during maintenance.

- A Disconnecting Switch/ Isolator: The function of a disconnecting switch in a High Voltage Switchgear is to interrupt small currents which are capacitively coupled or induced.

- Protective relays: This component helps in detecting any fault within the High Voltage switchgear and relays it to the circuit breaker.

How does High Voltage Switchgear Work?

Overloading of the line inhibits the current from making an electromagnetic release action.

However, it initiates the production of heat by the thermal element.

The heater heats the bi-metal sheet causing it to bend upwards.

This pushes the lever upwards, making the hook to lock off.

This breaks off the primary contact, cutting power supply off.

By doing this, when there is an overload, it exceeds the set current causing the electromagnetic tripper to produce suction.

A combination of the suction and the impact lever results in the lap hook to rotate upwards around the

Shaft seat, thereby releasing the lock.

What is the difference between High Voltage Switchgear and High Voltage Switchboard?

High Voltage Switchgear has switching devices and components like lightning arrestors, circuit breakers, isolators, and relays.

These components regulate current flow in an electrical circuit.

High Voltage Switchboard refers to a panel consisting of switches, electrical and protective control devices and buses.

The function of a High Voltage Switchgear is to switch on and power motors, generators, transformers and transmission lines for industrial and commercial use.

They help in supplying, protecting, and controlling power loads.

A switchboard is used in the distribution of power to different sources and to transmit it to specific, transformers, control equipment, and transformers.

A high Voltage switchboard handles Voltages of up to 600 Volts.

A high Voltage Switchgear handles a voltage range of above 36kV.

High Voltage Switchgear is expensive when you compare to a High Voltage Switchboard.

A High Voltage Switchgear is bigger than a High Voltage Switchboard.

This is because of the front and rear access that it has, which is important during maintenance.

A high Voltage Switchboard has a 20% testing power factor for a 3-cycle duration.

A High Voltage Switchgear has a 15% testing power factor for 30 cycles.

How does High Voltage Switchgear and Control Gear Compare?

The function of a High Voltage Switchgear is to distribute power in industrial and commercial applications. Control gear is for controlling and protecting electrical equipment.

What is the Voltage Range for High Voltage Switchgear?

The voltage range for a High Voltage Switchgear is any current above 36kV.

How can you Test High Voltage Switchgear?

The following are the tests necessary for a High Voltage Switchgear:

- Test of the measure of the gas condition

You need to measure the pressure of the gas as well as the moisture content of the Gas Insulated Switchgear.

Ideally, the gas should be 100ppm for the components and 50ppm for the circuit breaker poles.

This test ensures that the switchgear functions appropriately.

- Resistance test

You need to check the resistance for every busbar and outgoing terminals during the erection process.

You need to check the results against those prescribed by the manufacturer.

- Current transformer core test

You need to test the ration and polarity of the current transformer core and compare the results to the primary current injection. You need to perform this test phase by phase.

- Gas tightness test

This test analyzes any leakages within a High Voltage Gas switchgear using a gas leak detector.

- Dielectric test

The dielectric test is on the auxiliary circuits.

For this test, apply 500 voltage DC between the terminal blocks and the earth point.

- High voltage tests on the main circuit

You need to check on the dielectric strength to remove causes like damage during handling, wrong fastening, and presence of foreign bodies.

Such issues may result in an internal malfunction of the switchgear of not addressed.

What are the Types of High Voltage Switchgears available?

Types of high voltage switchgear

The types of High Voltage Switchgears that are available are:

- Air Insulated High Voltage Switchgear. This type uses air as the main insulating material for conductive components in the switchgear.

- Gas Insulated High Voltage switchgear. It is a type of high voltage switchgear that uses superior dielectric gas (SF6) as the main insulating material for conductive elements within the switchgear.

How does Gas Insulated High Voltage Switchgear compare to Air Insulated High Voltage Switchgear?

Air-insulated High Voltage switchgear uses air as an insulation material for its electrically conductive parts.

Gas-insulated High Voltage switchgear uses gas as an insulation material for its electrically conductive parts.

Installation of Gas-insulated High voltage switchgear is quite easier and faster than installing air-insulated High Voltage switchgear.

This is because Gas-insulated High Voltage switchgear is relatively smaller in size and requires a small space for installation.

Gas-insulated High Voltage switchgear is relatively easier to operate than Air-insulated High Voltage switchgear.

This is because of its front access feature. Also, they consist of integrated testing tools that facilitate operations.

The occurrence of arc flashes during operation is rare in gas-insulated High Voltage switchgear that occurs in air-insulated High Voltage switchgear.

This is because of the total insulation of the inner parts of the gas-insulated High Voltage switchgear.

The maintenance process of gas-insulated High voltage switchgear is cheaper when you compare to air-insulated High Voltage switchgear.

This is due to copper corrosion, which is prone to air-insulated High Voltage switchgear.

The purchasing cost of air-insulated High Voltage switchgear is lower when you compare to gas-insulated High voltage switchgear.

However, the overall running cost of air-insulated High voltage switchgear is higher than that of gas-insulated High Voltage switchgear.

What is the difference between Dead and Live Tank Type Circuit Breaker?

In a dead tank Circuit Breaker, the location for the switching devices is inside the metallic vessel inside a ground potential.

The switching device has suitable insulators, while an insulation medium submerses the ground potential.

A live tank Circuit breaker consists of a switching device located on bushings that are insulated having the same potential.

The cost of live tank circuit breakers is cheaper when you compare to that of dead tank circuit breakers.

What are the Features of High Voltage Switchgear?

The features of a High Voltage Switchgear are:

- Space

High Voltage Switchgears offer different sizes of switchgear depending on your requirements.

This gives you the chance to select the one that will fit the space available and the application.

- Reliability

High Voltage Switchgear offers a reliable way of ensuring there is no power interruption within your electrical component.

This is through the prevention of electrical faults from occurring.

The zero-maintenance feature allows for fewer power interruptions, which ensure that individuals and plants get to enjoy power services.

- Creepage distance

This is a measure of the smallest distance on the surface of the insulation between two conductive materials.

Due to electric discharge, corrosion takes place around the surface of this region.

It is, therefore, important that you maintain the creepage distance through a process called tracking.

You need to consider the comparative tracking index and the level of atmospheric pollution when checking on tracking.

- Clearance distance

Clearance distance is the smallest distance through the air between two conductive materials.

It is critical in preventing dielectric breakdown that occurs between two electrodes due to air ionization.

- Maintenance

The ease of accessing components within the High Voltage Switchgear offers an easy way of maintenance during fault occurrence.

How do you Troubleshoot High Voltage Switchgear?

Troubleshooting a High voltage Switchgear depends on the source of the problem.

The common troubleshooting procedures for High Voltage Switchgears include:

- You cannot lock the handle

This problem arises from the rusting of the internal locking mechanism or a faulty locking mechanism.

It may also be that you are using the wrong key to open up.

To solve this problem, ensure that you use the correct key.

You need to lubricate the locking mechanism or replace it altogether.

- Internal noise

the cause of your switchgear producing internal noise is due to the electromagnetic induction screws that are on the partitioning plates.

Cable touching gland plates are another source of the internal noise.

Ensure that you have tightened the screws on the portioning plates and applying a layer of sealant on the cable.

- Overheated connections

This is a result of having bolts that are overhead and loose.

To solve this, ensure that you use the rated current value.

Also, tighten any loose bolt and replace the busbar if necessary.

- The switchgear fails the dielectric test or ground fault.

Cracked insulators cause switchgear to fail the dielectric test or ground fault.

This. Such insulators are prone to moisture or foreign contaminants.

To solve this, you need to replace the insulators.

You can also clean using an appropriate cleaning agent and dry the moisture parts.

- Shutters not closing

The main reason why the shutter is not closing is due to damaged shutters.

To solve this, you need to repair the shutters and clean the adjustable parts.

You can also apply a lubricating oil in these parts to facilitate the closing.

- Indicating light extinction

Indicating light extinction may be as a result of the following:

Fuse or resistor burnt, Broken bulb filament, faulty limit switch contactor poor contact of the auxiliary switches.

You need to check on the following to fix this: change the bulb, replace the fuse or resistor, cleaning of the auxiliary contacts, or monitor the MCCB of the fuse terminals.

- Poor control unit operation

Poor control unit operation maybe because of unfastened screws of the terminal blocks.

Alternatively, it can be due to an improper connection of the control plug.

You need to tighten the screws for the terminal blocks.

You can also connect the control plugs appropriately.

- Shutters are not opening

If your shutters are not opening, it may be due to poor adjustment of the moving parts or lack of lubricating in these parts.

Also, it can be due to deformed shutters.

To solve this, you need to adjust and lubricate the moving parts and check on the shutters to ensure they are incorrect shape.

How do you Maintain High Voltage Switchgear?

High voltage switchgear

Maintaining a High Voltage Switchgear requires you to undertake two maintenance procedures.

· Regular maintenance

This is a type of maintenance that involves checking on the operational level of your air-insulated switchgear.

Proper adjustment of the operating conditions, as well as having a fault history, is necessary for regular maintenance.

Regular maintenance also involves checking on the meter readings and correcting any abnormality.

You need to check on the metal parts for any rusting and peeling of the metal paint.

The peeling of the paint can be an indicator of the overheating of the air-insulated switchgear.

Use a temperature sensor to note such variation.

Rusting affects the quality of the air-insulated switchgear and its overall performance in the long run.

If you notice such, you need to replace the section for the effective working of your air-insulated switchgear.

· Yearly maintenance.

Involves checking on the performance of the air-insulated switchgear every year.

This is to compare the variation in terms of its working and also to rectify electrical faults of the air-insulated switchgear.

Yearly maintenance also involves applying a fresh coat of paint to the metallic parts of the switchgear.

Paint helps in minimizing rusting and corrosion of the metal parts.

Is there a Difference between Current Interrupter and Switchgear?

The function of a Current Interrupter is to cut off the circuit when there is a current leak within the circuit.

A Switchgear interrupts the current in an electrical circuit when there is an overload within it.