This is an article containing all the information related to XLPE cables. By reading this article, you will get a comprehensive understanding of XLPE cable, whether it is right for your project, and how to choose the right XLPE cable.

What Is XLPE Cable?

XLPE cable is a type of cable that uses cross-linked polyethylene (XLPE) as an insulation material.

The full name of XLPE is Cross-linked Polyethylene, a thermosetting material formed by cross-linking ordinary PE (polyethylene). Cross-linked XLPE is more resistant to heat and aging. It is an excellent cable material.

Because of its stable structure and excellent performance, XLPE cable is commonly used in harsh environments such as outdoor, direct burial, high temperature, and industrial. It is also widely used in low, medium, and high voltage power transmission and distribution systems.

Why Use XLPE Cable? What Are The Benefits of XLPE?

High and Low Temperature Resistant

XLPE cable can work stably in both high and low temperature environments. It is heat-resistant and does not become brittle at low temperatures. It is suitable for working environments with high temperatures or large temperature differences.

Resistant to Abrasion, Pressure, and Corrosion

XLPE insulation has excellent mechanical strength and is not easily damaged by stretching, extrusion, or abrasion. It is also resistant to oil, salt, and a wide range of chemicals, so you can use it outdoors, underground, or in industrial sites with confidence.

Stable Electrical Performance

XLPE has high insulation resistance and low dielectric loss, and is stable under continuous operation and high load conditions.

Moisture Resistant, Water Resistant, Direct Burial Capable

XLPE insulation does not absorb water, allowing it to be used for long periods of time in wet, waterlogged, or direct burial environments. This helps you minimize failures due to moisture.

Long Life, Low Maintenance

XLPE material does not age, crack, or harden easily and has a relatively long life. It is not likely to fail and needs less maintenance, helping you reduce long-term operating costs.

Supports Higher Voltages

XLPE’s high electrical strength allows it to be used in low, medium, and even high voltage systems. So XLPE cable covers more types of power distribution applications.

What Are Some Common Applications of XLPE-Insulated Cables?

XLPE-insulated cables are widely used. Often used in:

- Power transmission lines: for power transmission over long distances and at higher voltages. XLPE cables ensure stable and safe operation.

- Urban power distribution networks: connecting substations to residential and commercial buildings and factories, it is often the choice for low-voltage and medium-voltage power distribution systems.

- Industrial environment: suitable for metallurgy, oil refining, chemical industry, pharmaceuticals, etc. It can resist oil, chemical corrosion, and mechanical shock.

- Underground and tunnels: resistant to humidity and chemical corrosion, commonly used in underground cable trench, tunnel, subway, and other areas with limited space and complex environments.

- Submarine and underwater equipment: can be used for underwater wiring and some shallow sea cable systems, can withstand pressure, moisture, and long-term immersion in water.

- Building and public facilities: Used for main power supply and lighting lines in hospitals, schools, stadiums, airports, shopping centers, and other places.

- Automotive & transportation equipment: On-board XLPE wiring harnesses are heat-resistant, abrasion-resistant, lightweight, and suitable for high-temperature environments such as engine compartments and chassis.

- Solar and renewable energy systems: commonly used in the connection between photovoltaic power generation equipment and inverters, and can withstand high outdoor temperatures and UV exposure.

- Outdoor lighting and municipal projects: Used for road lighting, garden lighting, landscape projects, etc., that require long-term open-air operation.

What Are the Advantages of XLPE Cables Compared with PVC Cables?

XLPE cable performs better than PVC cable in many ways.

- It can withstand higher voltages and mechanical stresses and is therefore used in more demanding scenarios, whereas PVC can only be used for low voltage or general applications.

- XLPE has a wider temperature range than PVC and can be used at higher temperatures.

- XLPE is more resistant to moisture, and its performance is less likely to be affected in wet, underground, and outdoor environments.

- It also has a longer service life and is not prone to aging and cracking in long-term use.

- At the same time, XLPE is chlorine-free and does not release corrosive or toxic gases when burned. It is kind to both the equipment and the environment.

What Types of XLPE Cables Are Available?

By voltage

- Low-voltage XLPE cables (LV): rated voltage up to 1kV, commonly used in homes, offices, and general industrial power distribution.

- Medium voltage XLPE cables (MV): up to 35kV, suitable for power distribution in industrial parks, commercial buildings, and large residential complexes.

- High-voltage XLPE cables (HV): up to 500kV, used for long-distance transmission and urban backbone power networks.

By the number of conductors

- Single-Core XLPE cables: mostly used for high voltage or high current applications.

- Multi-Core XLPE cables: include multi-stranded flexible constructions like RVV for control, distribution, and equipment connections.

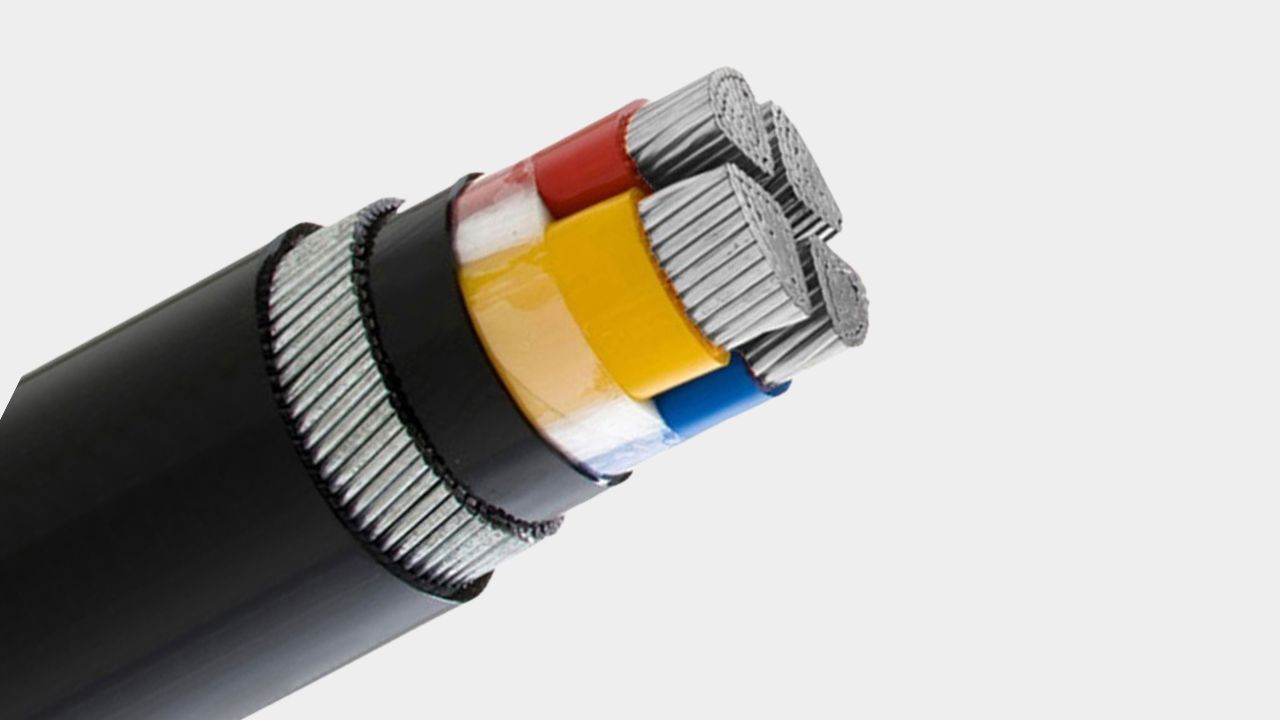

By armor

- Armored XLPE cables: Armored with steel wires or bands to resist mechanical stress and external damage, for underground, industrial, and high-abrasion environments.

- Unarmored XLPE cables: lighter construction, for indoor or better-protected installations.

By use

- Fire-Resistant XLPE cables: keep power supply for a certain period of time in the event of a fire, and are used for emergency systems and critical equipment.

- Instrumentation XLPE Cable: For signal transmission, commonly used in industrial control systems and automation equipment.

What Cable Models Are Insulated with XLPE?

- Building & Indoor Wires: XHHW, XHHW-2, RHH, RHW, RHW-2

- Outdoor & Direct-Burial Cables: USE-2, PV Wire/PV Cable, as well as some XLPE-insulated tray cables (TC, TC-ER)

- Power Distribution Cables: LV, MV, and HV XLPE power cables, as well as armored XLPE cables in a variety of configurations (such as XLPE/SWA/PVC, XLPE/LSZH, etc.)

These models cover many applications from construction to industry. If your project requires cables that are heat and moisture resistant or stable over time, XLPE insulation is often the smart choice.

Is XLPE Insulation UV-Resistant?

Yes. The XLPE material has good weather resistance and can generally withstand long-term outdoor UV exposure. This is why it is often used in photovoltaic cables, outdoor cabling, and sun-exposed settings. However, the exact UV resistance also depends on the cable type and sheath material. If the cable is to be used under strong sunlight for a long time, you need to choose XLPE cables with the UV-resistant label or with a black UV-resistant jacket.

What Temperature Can XLPE Cable Withstand?

The normal operating temperature of XLPE-insulated cables is 90°C. In higher grade XLPE constructions, the cables can be operated for long periods at 105°C or 125°C. In the event of a short circuit, XLPE cables are able to withstand even higher temperatures, typically around 250°C, for several seconds without affecting the structure.

How Long Does XLPE Cable Last?

XLPE cables typically have a service life of 30-50 years, which can be affected by the installation environment, load levels, temperature, humidity, and mechanical stresses. XLPE insulation is inherently resistant to heat, moisture, and aging, so it is stable for long periods of time under normal conditions. If used outdoors, underground, or in industrial environments, it can also achieve a high level of longevity, as long as the installation is standardized. Overall, XLPE cables are a long-life, low-maintenance type of cable.

Is XLPE Cable Flame-Retardant or Fire-Resistant?

XLPE cables have good heat and flame resistance, but they are not fire-resistant.

If you require the cable to keep powered during a fire (e.g., fire pumps, evacuation lighting, or emergency systems), it is important to choose a fire-resistant cable with a specialized fire-resistant construction, such as a mica tape or ceramic layer, rather than ordinary XLPE insulation.

Is XLPE Cable Halogen-Free or Low-Smoke?

XLPE itself is halogen-free, so it is a halogen-free material. But whether it is low smoke depends on the outer jacket. Many XLPE cables are made with an LSZH outer jacket, so that the whole cable can be low-smoke and halogen-free. If XLPE cables use PVC outer sheath, then they are not low smoke.

What Is the Maximum Current-Carrying Capacity of XLPE Cables?

XLPE cables do not have a fixed value for current-carrying capacity, which varies according to core material, voltage class, conductor structure, ambient temperature, laying method, etc.

Generally speaking, XLPE is rated for operating temperatures up to 105°C, so it usually has a higher current-carrying capacity than PVC cables of the same size. The common current-carrying capacity of low-voltage XLPE cables ranges from about several tens to several hundreds of amperes, while medium-voltage cables can reach several hundred to several thousand amperes.

In practice, you will need to decide the current-carrying capacity based on the cable’s standardized current-carrying capacity table and the installation environment.

Which Standards Apply to XLPE Cables (UL, IEC, BS, ICEA)?

XLPE cables correspond to a variety of standards in different countries and applications. The common standards are as follows:

- UL Standard (USA): principally adopted for building and equipment cables, such as UL 44, XHHW-2, RHH, RHW-2, UL 854, USE-2, and UL 4703.

- IEC standards: international, mainly applied to power cables, such as the IEC 60502-1 for low voltage and IEC 60502-2 for medium voltage.

- BS Standards (UK): Common types include BS 5467 (XLPE/SWA/PVC) and BS 6724 (XLPE/SWA/LSZH).

- ICEA/NEMA Standards(North American Electric Power Industry): XLPE power cables for electric utilities and industrial systems, e.g., ICEA S-93-639, ICEA S-97-682.

What Is the Difference Between XLPE, EPR, and PE Insulation?

PE is a common polyethylene insulation with good dielectric properties, but not high in temperature resistance. The commonly rated temperature is only about 70℃, and it is not suitable for use in occasions with high mechanical strength; it is mainly used for low-voltage, telecommunication, or weak power cables.

XLPE temperature resistance has been greatly improved to 90℃, 105℃, and even 125℃. It has better heat resistance, moisture resistance, and insulation strength. It is currently the most common insulation material for low-, medium-, and high-voltage power cables.

EPR stands for ethylene propylene rubber insulation. It offers optimal flexibility, small bend radius, consistent heat resistance, and reliable electrical performance in harsh industrial scenarios and mobile equipment cables. The cost is usually higher than that of XLPE.

Briefly:

PE has a good economy but average performance, XLPE is all-around and economical, while EPR is softer, consistent, and much more expensive.

Do XLPE Cables Require Special Installation or a Bending Radius?

The installation of XLPE cables does need to pay attention to some basic requirements, particularly when it comes to bending radius. XLPE insulation is hard, and too small a bend may damage the insulation layer; so it is generally necessary to follow the minimum bending radius given by the manufacturer or the standard for construction. The bending radius will be different for different voltage levels and with or without armor.

In addition, you should avoid violent pulling, excessive twisting, and strong impact during the installation process. During dropping, threading, or entering the bridge, the cable should always be kept uniformly stressed, and sharp turns minimized. If the construction is in a low-temperature environment, the cable might harden, and preheating or increasing the temperature of the construction in advance is recommended.

How Do I Choose the Right Size of XLPE Cable?

To choose the right size of XLPE cable, you can follow these steps:

- See how much current the equipment needs. The higher the current, the thicker the cable should be.

- Confirm the voltage level to be used. The higher the voltage, the higher the insulation strength of the cable.

- Look at how the cable is installed. Different ways, such as direct burial, through the pipe, overhead, etc., will affect the current that the cable can carry.

- If the distance is long, you need to choose a larger cross-section in order to reduce the voltage drop.

- High temperatures will make the cable “unbearable”, need to increase the size.

- If with a motor or will have a large inrush current. It is recommended to leave a little more margin, choose a larger cable.

- Whether the capacity will be expanded in the future. If the load may be added later, reserve a larger size now.

Based on these, you can basically determine the appropriate XLPE cable size. If you’re not sure, give Honest Cable your project information, and we can help you.

Can XLPE Cable Be Customized?

XLPE cables can be customized in many ways, such as whether the conductor is made of copper or aluminum, how many cores, how large the cross-section, how long the cable needs to be, what color it is, how it is packaged, etc. The outer material, armoring, and shielding can also be selected according to the requirements.

If your project has special requirements, such as high temperature, direct burial, UV, oil resistance, or a higher flame-retardant grade, it can also be done. You tell us the usage environment and basic parameters, and we will help you to make a suitable XLPE cable program.

What Are the Disadvantages of XLPE Cables?

XLPE cable also has some things to be aware of. It is more expensive than regular PVC cables and should be considered if you are on a budget.

Although XLPE can withstand high temperatures for short periods of time, prolonged overheating or overloading will accelerate deterioration.

In addition, it is not inherently flame-retardant, and fire resistance depends on the outer jacket.

In very cold environments, the cable hardens and can be easily damaged when bent.

In addition, the production process of XLPE is demanding, and the quality of XLPE varies greatly between manufacturers, so special attention should be paid when purchasing.

Does XLPE Cable Cause Interference or Require Shielding?

XLPE cables do not produce interference by themselves. Shielding is not required for normal power lines in homes or factories. However, if there is equipment next to the cable that is susceptible to interference, or if the cable is used to transmit signals, a layer of shielding can be added to protect the signals from being affected. Whether to add shielding or not depends mainly on the use of your cable and the installation environment.

Final Thought

After reading these FAQs, if you still have some questions or are still uncertain about which XLPE cable is ideal for your project, Honest Cable can assist. The professional team provides technical support and quality service to help you quickly find a reliable, high-performance cable solution to make your work more efficient and reassuring.