Whether you are an electrical contractor or a construction brigade, knowing how to properly and safely install distribution boxes is the basis of ensuring the safe operation of the entire system. This article details the process of installing them, which helps you comprehend distribution boxes better.

Now let us dive in.

¿Qué es una caja de distribución?

First of all, you need to have a simple understanding of the definition of a distribution box, and make it clear which kind of distribution box you want to install. This is important to properly install it. Strictly speaking, the word “Distribution Box (D-box)” can refer to two categories: electrical distribution boxes and septic tank distribution boxes. This article mainly talks about the first one.

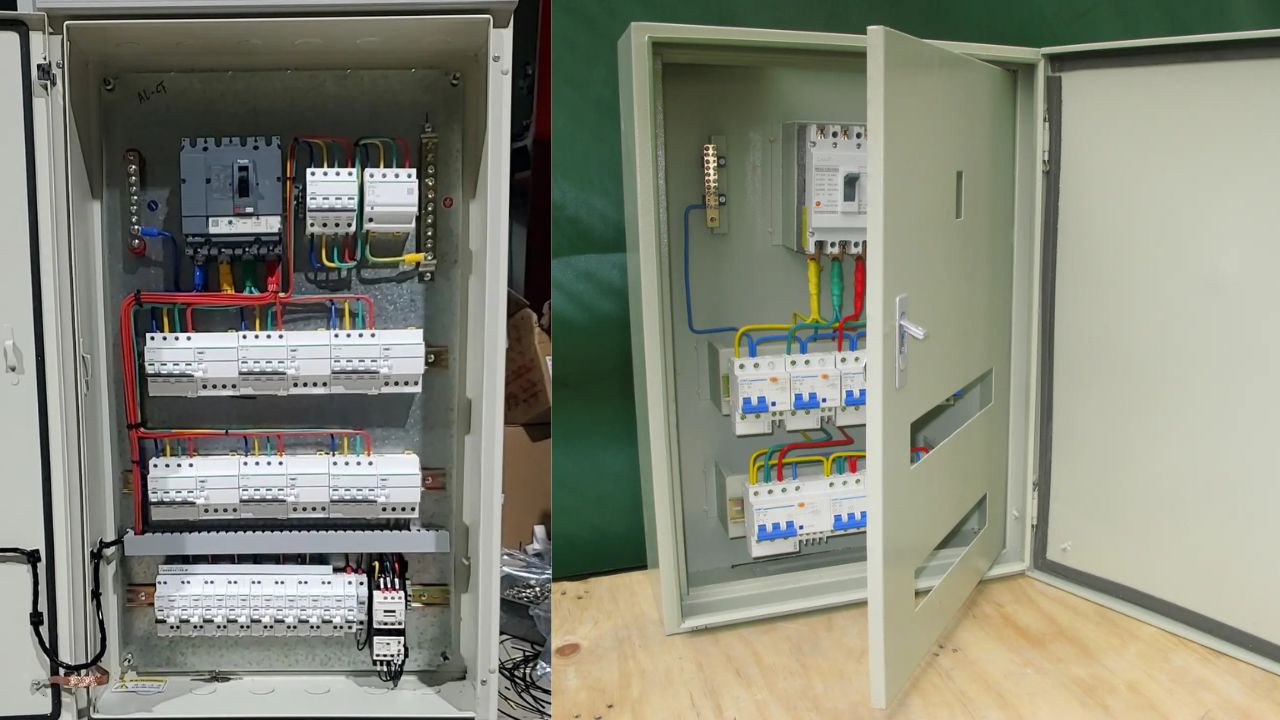

An electrical distribution box, also known as a power distribution box, panelboard, or consumer unit, is the core of an electrical system. It has three categories: residential, commercial and industrial electrical distribution boxes, all of which play important roles in their respective electrical fields.

Distribution boxes contain many protective devices like circuit breakers, fuses, and isolator switches to distribute and regulate power from the main power supply to multiple circuits in other buildings, and to prevent damage and fire hazards, usually installed in electrical rooms, basements, or corridors. Some advanced models may also include Residual-Current Devices (RCDs) or Residual Current Breakers with Overcurrent Protection (RCBOs).

Choose the Best Position for Installing

Before starting the installation, finding a proper place for putting the distribution box is crucial, because it largely decides the safety and convenience of maintenance. Let’s see what factors need to be taken care of when choosing the installation place.

- Accesibilidad

Accessibility is one of the most important factors that you need to take into account when choosing the installation place. The position needs to be close to the main power supply

to connect. Besides, it should be easy to find and convenient to access by electricians and maintenance personnel, which is helpful to prevent electrical faults and to maintain them.

- Ambiente

The ideal location to install electrical distribution boxes should keep a distance from water, flammable and explosive substances and corrosive substances. If they need to be placed outdoors, especially in high humidity, you must ensure their waterproofness. If necessary, equipping a rain cover, cooling fan or dehumidifier will be better.

- Capacity

Remember to leave enough space around the box for better ventilation and maintenance. The capacity must be large enough to accommodate wiring and circuit breakers, and to be ready for future system expansion or upgrade.

- Altura

The best height for installing residential distribution boxes is 1.5 meters above the ground, while for industrial distribution boxes, the height depends on the space and the equipment around.

Choose a Suitable Caja eléctrica for your Electrical Distribution Box

When preparing the tools and materials that are needed for installation, an electrical enclosure is a necessity, so choosing a suitable electrical enclosure is an essential part before the formal installation.

- Clasificaciones IP y NEMA

Usually, electrical enclosures are used to protect the Internal electronic components of distribution boxes from water, dust and damage. When choosing electrical enclosures, you need to consider their IP and NEMA ratings, which represent their protective level. IP is a global standard, whose first digit represents solids protection and the second digit represents liquids protection. Common NEMA ratings include NEMA1 (for basic indoor protection) and NEMA 4 (for corrosion resistance).

If your distribution box is installed outdoors and exposed to rain and sunlight, you need to select an electrical enclosure with a higher protection level, such as models with IP66 or NEMA 4 ratings.

- Materiales

Electrical enclosures are made of various materials, and all of them have their unique characteristic. Usually, Acero is strong and affordable, but with a lower corrosion resistance; Acero inoxidable has a very high corrosion resistance; Plastic (Polycarbonate/ABS) is lightweight, cost-effective, non-conductive, and often UV-resistant, suitable for outdoor use; Fiberglass (FRP) is strong with good insulation, which can resist harsh environments.

- Size and Compatibility

The size of the electrical enclosure should be sufficient to meet the current and future equipment requirements, and should guarantee good air circulation to prevent overheating. You can add cooling if necessary.

For more information, you can check our product page. We have lots of choices for you to choose from.

The Process of Installing a Distribution Box

Here is the most important part—the process of installing a distribution box. Take care that we strongly recommend that you look for a professional electrician. The installation of distribution boxes requires professional electrical knowledge and operational skills. It’s very dangerous for an amateur to do this because any errors can cause electrical accidents

such as short circuits, or even fire disasters and electric shock.

Now, let’s introduce it step by step.

Tools and Materials Preparation

First of all, properly prepare all the tools and materials that need to be used.

- Necessary tools include screwdriver, wire stripper, electric drill, multimeter, and an insulation resistance tester.

- Necessary materials include an electrical enclosure, expansion bolts, fixing brackets, screws, terminal blocks, qualified wires, cable ties, insulating tape, etc. Inspect all of them and ensure that they are intact.

- Necessary personal protective equipment also can’t be ignored. Those include insulating gloves, cut-resistant gloves(can be worn inside insulating gloves), safety glasses, FR Clothing, slip-resistant shoes, etc.

Fix the Box

- Mark and Drill: Confirm the installation place (the method is above) and mark on the wall or installation surface with a marking pen. Then drill holes with the appropriate size by an electric drill, and insert expansion bolts.

- Distribution Box Installation: Put the distribution box on the installation surface, and align the position of the expansion bolts and tighten the screws. This step needs to be checked carefully, ensuring that the distribution box is installed stably without any inclination or looseness.

Wiring Connections

- Wire Preparation: Cut the insulation layer of the wire, leaving a suitable length of the exposed conductor.

- Cortacircuitos: Install independent circuit breakers according to your electricity usage requirements.

- Termination: On this step, you must connect each conductor to its designated terminal: line to line, neutral to neutral, and ground to ground. Follow the color coding standard. Connect the input and output wires to the corresponding terminals of the distribution box. Then press the wire onto the terminal with a wire stripper, or tighten the wire with screws. This step is very crucial and can not bear any faults!

- Circuit Label: After the circuit connection is completed, you need to mark each circuit correctly, which is helpful for maintenance and troubleshooting in the future.

- Wiring Layout: Dress and route all wires neatly within the enclosure, and secure them with cable ties. Leave some space for heat dissipation. Be careful that the wires are not tangled and avoid touching the sharp edges.

Safety Checks

Now the installation is completed, and you can reconnect the power supply to do the following tests and checks:

- Prueba de resistencia de aislamiento: Use a qualified insulation resistance tester to measure the resistance between the wiring and the box to verify that the reading meets or exceeds the required value.

- Circuit On/Off Test: Check if there are any broken wires or short circuits in the on/off status of each circuit with a multimeter.

- Component Verification: Finally, verify the correct installation and operational status of all internal components (e.g., circuit breakers, fuses). Additionally, confirm that their rated current and voltage values comply with the circuit design requirements.

If you find any abnormal conditions during the installation or checking, cut off the power supply immediately and contact professional maintenance personnel to process. Never disassemble or repair the box by yourself if you are not a professional.

Maintenance and inspection after installation

After completing the whole installation process, you can have a rest, but don’t forget these maintenance and inspections for your distribution boxes.

- Daily inspection

You can conduct a brief inspection of the distribution box as follows: Check the enclosure for any physical damage, corrosion, or signs of water ingress. Observe status indicators on internal components (e.g., circuit breakers, RCDs). Be alert for any abnormal sounds (e.g., humming, buzzing) or unusual odors (e.g., burning smell).

- Scheduled maintenance

- Clean the inside and outside of the distribution box to remove dust, debris and other contaminants that may affect heat dissipation and insulation performance.

- Check whether the connection terminals are securely fastened, and re-tighten any loose screws

- Inspect the wear condition of the wires and replace the damaged ones in time.

- Test the operating performance of protective components such as circuit breakers and fuses to ensure that they can respond properly in the event of a fault.

Common Safety Standards

When installing distribution boxes, you need to follow the regulations. Distribution box manufacturing and installation are governed by internationally recognized and regional safety standards. Key benchmarks include the International Electrotechnical Commission (IEC) standards for low-voltage switchgear, the US National Electrical Code (NEC), and China’s GB 7252 standard.

Tips for Installing Distribution Boxes That You Should Know

Some points of installing you may ignore but are also very important. Let’s learn about them.

- Keep power-off state: You must check the electrical tester at the beginning, making sure the whole installation place is in a power-off state.

- Possible problem: Short circuit, bad contact or arc phenomenon can be caused by many issues that you may ignore during the installation process, such as the phase wire and neutral wire being connected in reverse, the terminal connections being loose, and the conductors being overly exposed, etc. So when the problems occurred, you can check these parts one by one (remember to keep the power off).

- Risk of Mismatched Components: The use of circuit breakers or fuses with incorrectly rated parameters compromises protection, potentially resulting in failure to isolate faults or excessive nuisance tripping.

- Reliably grounded: Reliable grounding of the distribution box is critical to prevent electrical shock and other safety hazards. The grounding wire should have an adequate cross-sectional area to connect to the grounding network.

- Wire’s degree of thinness: It is essential to use wires that match the rated current and the expected current load. Overly thin wires can cause overheating and lead to fires.

- Keep the installation record: A clear record of wire size, circuit breaker rating, layout details, etc, is helpful for future inspections, upgrades or repairs.

- Extreme weather conditions: If the distribution box has encountered any extreme weather conditions such as thunderstorms, heavy rain, high temperatures, etc., you need to additionally check it to ensure that the equipment is still intact and the circuitry is free of faults.

Preguntas frecuentes

What is the Price of Electrical Distribution Boxes?

An electrical distribution box can cost from several hundred to several thousand dollars. The specific price depended on your custom requirements.

What are the common sizes for Distribution Boxes?

The enclosure size is primarily determined by three factors: 1. The number of branch circuits required. 2. The physical dimensions of internal components (e.g., circuit breakers, RCDs). 3. The necessary wiring space for safe and compliant installation. Typically, the size of a residential distribution box ranges from 4 to 20 circuits, while commercial and industrial boxes can range from 20 to 40+ circuits.

How to Estimate the Size of the Box that I Want?

You can decide the size through the following steps:

- Figure out the number of electrical devices and the number of branch circuits.

- Select appropriate circuit breakers, fuses and other components based on each circuit‘s load.

- The distribution box size shall be selected based on the aggregate dimensions of the internal components and the required wiring space.

Can I Customize a Distribution Box?

Yes, distribution boxes can be customized according to specific application requirements, such as in high-temperature, high-humidity, corrosive or explosive environments. And it can also be customized with the corresponding protection level, material and structure according to the requirements.

How to Choose a Suitable Electrical Distribution Box?

When choosing an electrical distribution box, you can take the following factors into account:

- Operating environment: Electrical distribution boxes can be divided into residential, commercial, and industrial. Residential distribution boxes usually have a smaller size and lower weight, while industrial distribution boxes are specially designed for high power capacity requirements, such as factories, warehouses or construction sites.

- Electrical Load: Choose distribution boxes that can contain a little bit more electrical load than your demand, because a too-small distribution box may cause frequent tripping of the circuit breaker or system failure.

How does a Distribution Box Work?

The operating principle of an electrical distribution box is to receive electricity from the primary power line and distribute it through outlets, protecting circuits from overloading.

What’s the Difference Between Distribution Boxes and Cajas de conexiones?

Distribution boxes are used for power distribution, circuit protection and cable management, while junction boxes are only used for wire connection and branching.

What is the recommended inspection schedule for Distribution Boxes?

The recommended inspection and maintenance frequency should be adjusted based on the application environment and load criticality.

| Solicitud | Routine Inspection | Scheduled Maintenance |

| Residential | Every 3-6 months | Every 1-2 years |

| Comercial | Every 1-3 months | Every 6-12 months |

| Industrial | Monthly | Every 3-6 months |

How to Choose the Right Distribution Box Supplier?

You can take the following factors into account when selecting a distribution box supplier:

- Product quality and certification: The boxes of the supplier must comply with international and national standards and possess relevant certifications.

- Technical strength: Choose suppliers that can provide professional model selection guidance, installation technical support and customized solutions.

- Personalización: Can the supplier meet your custom requirements(extreme temperatures, corrosive atmospheres, space constraints, etc.)?

- After-sales service: If the supplier can offer timely maintenance services, spare parts supply, technical consultation, etc.

- Industry reputation: Check the supplier’s reputation by market research and online reviews.

KDM: Provide the Best Electrical Enclosure for You

KDM specializes in making electrical enclosures and customizing them to adapt to various environments and applications. A suitable electrical enclosure is an essential part of an electrical distribution box. If you want to find an electrical enclosure that suits your box better, never hesitate to Contáctenos. In only 1 to 2 days, our engineers can design your recinto personalizado with all required features applied to your distribution boxes.