Electrical enclosures are of vital importance in industrial, electrical and mechanical applications. Mild steel and stainless steel, as common materials for electrical enclosures, often significantly influence factors such as strength, corrosion resistance, service life, cost and applicability. This article discusses the difference between mild steel and stainless steel in corrosion resistance, strength, appearance, welding and cost. Ultimately, it will help you in choosing the appropriate material for electrical enclosures.

What Is a Mild Steel Enclosure?

The корпус из мягкой стали refers to the equipment enclosure mainly made of low-carbon steel plates through processes such as cutting, bending, welding and surface treatment.

Mild steel can also be called low-carbon steel. It is an iron-carbon alloy with a relatively low carbon content (0.05% – 0.3%). It does not contain alloy elements such as chromium and nickel in its composition. Therefore, it has an extremely low cost but is also prone to rusting.

The corrosion-prone mild steel determines that all qualified enclosures need to undergo one or more surface treatment processes.

Характеристики: Mild steel is the most fundamental steel for industrial production and is easy to process, thus it has excellent cost-effectiveness. When properly coated, it also possesses outstanding physical strength and durability. Beyond its ease of processing, it can also be customized flexibly.

What Is a Stainless Steel Enclosure?

The корпус из нержавеющей стали is an electrical enclosure made from an alloy steel containing at least 10.5% chromium through processes such as cutting, bending, and welding. The common 304 stainless steel has a chromium content of approximately 18%. 316 stainless steel also contains molybdenum. Chromium is the key factor that prevents stainless steel from rusting.

Характеристики: Outstanding corrosion resistance is the core feature, which is also the key to its maintenance-free operation and extremely long service life. Stainless steel has extremely high strength and good toughness, which also results in its high processing difficulty.

Mild Steel VS Stainless Steel Enclosure: Key Differences

Коррозионная стойкость

Corrosion resistance is the most fundamental and essential difference between stainless steel and mild steel, which stems from the differences in chemical composition and the corrosion prevention mechanism.

Mild steel mainly relies on the surface coating to form a physical isolation for anti-corrosion protection. When your surface layer of mild steel is damaged, the iron elements inside will quickly react chemically with water and oxygen, and the corrosion reaction will rapidly spread to the surrounding areas.

Therefore, mild steel requires higher maintenance. You need to regularly check the coating condition and promptly repair the damaged areas to prevent the spread of rust.

Compared with mild steel, stainless steel mainly relies on its alloying element (chromium) to form a dense and self-repairing passivation film that chemically isolates the environment. When the passivation film is intact, there will be no corrosion. However, if chloride ions erode or mechanical damage occurs, stainless steel may suffer from pitting corrosion or intergranular corrosion, but it is usually not likely to spread.

The higher the chromium content of stainless steel, the more corrosion-resistant it is. Molybdenum elements can improve the ability to resist chloride ion pitting. Generally, 304 stainless steel performs well in common environments. You can apply 316 stainless steel in more demanding conditions. Moreover, you don’t need frequent maintenance.

Density Difference

If you think that stainless steel is heavier, it would be wrong. In fact, stainless steel is comparable in weight and density to mild steel. The difference in density between mild steel and stainless steel (304) is extremely small, and it can usually be ignored in engineering design and weight calculations.

The weight of an enclosure mainly depends on the thickness of the sheet and the structural design, rather than the use of carbon steel or stainless steel.

Strength Difference

Mild Steel vs. Stainless Steel Yield Strength: Mild steel is slightly higher than stainless steel. The typical yield strength of 304 stainless steel is 205-210 MPa, which is slightly lower than mild steel. However, the yield strength of stainless steel can be improved through cold processing.

Mild Steel vs. Stainless Steel Tensile Strength: Mild steel has a tensile strength of about 350 to 500 MPa, and stainless steel has a higher tensile strength. The tensile strength of 304 stainless steel can reach 500-700 MPa. This also shows that stainless steel has a better potential to resist fracture. High-strength special or hardened grade stainless steel can even exceed 1000 MPa.

Mild Steel vs. Stainless Steel Hardness: Mild steel has a lower hardness and is more convenient for processing and cutting. Stainless steel has a higher hardness. This means that your stainless steel enclosure will be more durable, but the processing difficulty will also increase.

Mild Steel vs. Stainless Steel Ductility: Stainless steel has better ductility than mild steel. Austenitic stainless steel can still keep excellent toughness at low temperatures and has better impact resistance.

Appearance and Aesthetics

If you want to make the electrical casing more attractive, both mild steel and stainless steel are good choices. mild steel can be achieved through various surface coating processes such as порошковое покрытие, galvanizing, and painting. This aesthetic effect can provide a wide range of colors and high consistency for you.

The aesthetic of stainless steel mainly stems from the metallic luster and texture of the material itself, and it can be improved through physical or chemical treatments, such as sandblasting, mirror polishing, electrolytic coloring, etc. Unlike mild steel, you don’t have to worry about the risk of peeling or fading, and it can also display a more luxurious texture.

Сварка и изготовление

For cutting and punching, mild steel is softer and causes less wear to the cutting tools. Therefore, the processing difficulty is lower, the processing speed is faster, and energy consumption is lower. On the contrary, stainless steel has higher strength and better toughness, and due to the reason of work hardening, the processing of stainless steel requires larger power equipment and carbide tools.

Mild steel blending is superior to stainless steel blending in terms of plasticity, precise bending angle, and simpler mold design. However, the high yield strength and work hardening of stainless steel result in significant springback. Therefore, stainless steel production requires higher experience and technology.

For welding, mild steel can be welded using various techniques such as MIG and arc welding. The technical requirements for welders are relatively low, and the weld strength can be more easily guaranteed. Moreover, after welding, it only requires removing the slag and smoothing the surface.

The welding process for stainless steel is extremely demanding. Stainless steel is best welded using TIG welding, and it is necessary to apply a low-chromium coating and use specialized tools and facilities. Poor welding can significantly affect the corrosion resistance advantage of your enclosure. Moreover, after welding, the stainless steel must undergo pickling and passivation treatment.

Heat Transfer and Electromagnetic Shielding

In terms of thermal conductivity, mild steel outperforms stainless steel. Mild steel, as an excellent conductor, can effectively disperse local heat points. Stainless steel has poor thermal conductivity. The thermal conductivity of 304 stainless steel is only one-third that of mild steel.

Therefore, if your enclosure itself is designed as a heat sink, mild steel has a more obvious advantage. If your enclosure cooling mainly relies on internal fans, the influence of the material’s own thermal conductivity is relatively small.

Besides, the electromagnetic shielding performance of mild steel is extremely excellent. It mainly achieves outstanding shielding effects for low-frequency magnetic fields and high-frequency electromagnetic fields through absorption loss. Stainless steel also has good electromagnetic shielding performance, but it is closely related to the type of stainless steel.

Austenitic stainless steel is non-magnetic. Its shielding effect mainly relies on reflection loss and is more effective for electric fields and high-frequency fields. Martensitic stainless steel is magnetic, and its shielding performance is similar to mild steel.

Масса

From the perspective of material density, stainless steel is 0.6% to 3% heavier than mild steel. This gap is very small. The weight difference of the enclosure does not come from this.

The key to the weight difference lies mainly in the different design strategies adopted to meet the design requirements. The yield strength and tensile strength of stainless steel are significantly higher than those of mild steel. This also means that stainless steel can use thinner sections or smaller thicknesses to withstand the same load.

Secondly, corrosion margin is the factor that has the greatest impact on weight. In a corrosive environment, the design of your enclosure for mild steel requires an additional increase in material thickness to compensate for the metal that is corroded during its lifespan. However, under the same conditions, stainless steel does not require a margin.

Therefore, in engineering design, stainless steel has greater strength and no need for margin. As a result, its final product can achieve a more lightweight design compared to mild steel.

Расходы

Costs are often the key factor influencing your final choice. You can analyze it from two aspects: the initial cost and the total life cycle cost.

Initial Cost

The initial cost of mild steel has an overwhelming advantage. The raw material cost of mild steel is extremely low. It is one of the cheapest metal materials in industrial production. Moreover, mild steel is easy to cut, stamp, and bend, with low processing difficulty and cost.

Additionally, the welding process of mild steel is simple and mature, and the subsequent treatment is also very simple. However, the surface treatment cost of mild steel is very high. But overall, its total cost is still lower than the material price difference of stainless steel in the initial investment stage.

Total Lifecycle Cost

The full life cycle cost considers the total expenditure of a product throughout its entire service life. Undoubtedly, stainless steel has a higher value in terms of its total life cycle cost.

The installation and maintenance costs of stainless steel are almost negligible. Once installed, you don’t need to do any maintenance, and there are no costs for painting, checking for corrosion, etc. What’s more, the lifespan of stainless steel is extremely long. If you apply it in the right environment, its lifespan can easily exceed 50 years while keeping a good appearance. Moreover, stainless steel has a high scrap value and you can also recycle it.

On the contrary, the installation and maintenance costs of mild steel are extremely high. It requires you to conduct regular inspections, repaint, and repair the damaged areas. Besides, mild steel has a limited lifespan. Even with coating protection, its lifespan is affected by the maintenance cycle. If you apply it in corrosive environments, you may need to replace it after 10-20 years. Corrosion also brings high risks of failure and downtime, which can cause significant losses. Even if the material is scrapped, its scrap value is very low.

In conclusion, if you are more concerned about the initial investment and you plan to apply it in a dry and easy-to-maintain environment, mild steel (оцинкованная сталь) is your preferred choice. If your focus is on corrosion resistance, no maintenance required, high reliability, and long service life, or if your application installation environment is in a humid, coastal, or chemical environment, the economic benefits of stainless steel are more obvious.

Варианты использования

Корпус из нержавеющей стали

The core advantages of stainless steel application lie in its corrosion resistance, hygiene, long-term maintenance-free nature and superior appearance quality.

Food and Beverage Industry: For example, control cabinets for food processing assembly lines, enclosures of filling machines, etc. These equipment need to be rinsed and disinfected with high-frequency water at high pressure, steam, or acid-base cleaning agents. Moreover, the stainless steel surface is smooth and has no pores, which can effectively prevent the growth of bacteria and comply with FDA hygiene standards.

Chemical and Marine Engineering: In this environment, there are high concentrations of corrosive gases, acid fumes, and salt fumes. 316 stainless steel containing molybdenum can resist chloride pitting corrosion and is usually your preferred choice for such environments.

Outdoors and Harsh Environments: Such as outdoor communication base station cabinets, wind power control boxes in coastal areas, etc. These stainless steel equipment need to withstand long-term exposure to sunlight, rain, ultraviolet rays, extreme temperature differences, and sand erosion. The corrosion resistance and maintenance-free characteristics of stainless steel significantly reduce the lifecycle costs.

Корпус из мягкой стали

The core advantages of the application of mild steel enclosure are cost control, excellent strength and processing characteristics. You can apply them in a controllable indoor environment.

IT and Network Infrastructure: Such as server cabinets in data centers, network switch racks, patch panels, etc. These devices are deployed in data centers or telecommunications rooms with controlled temperature and humidity. Their core requirements are standardization, high-strength structure, good ventilation design, and low cost.

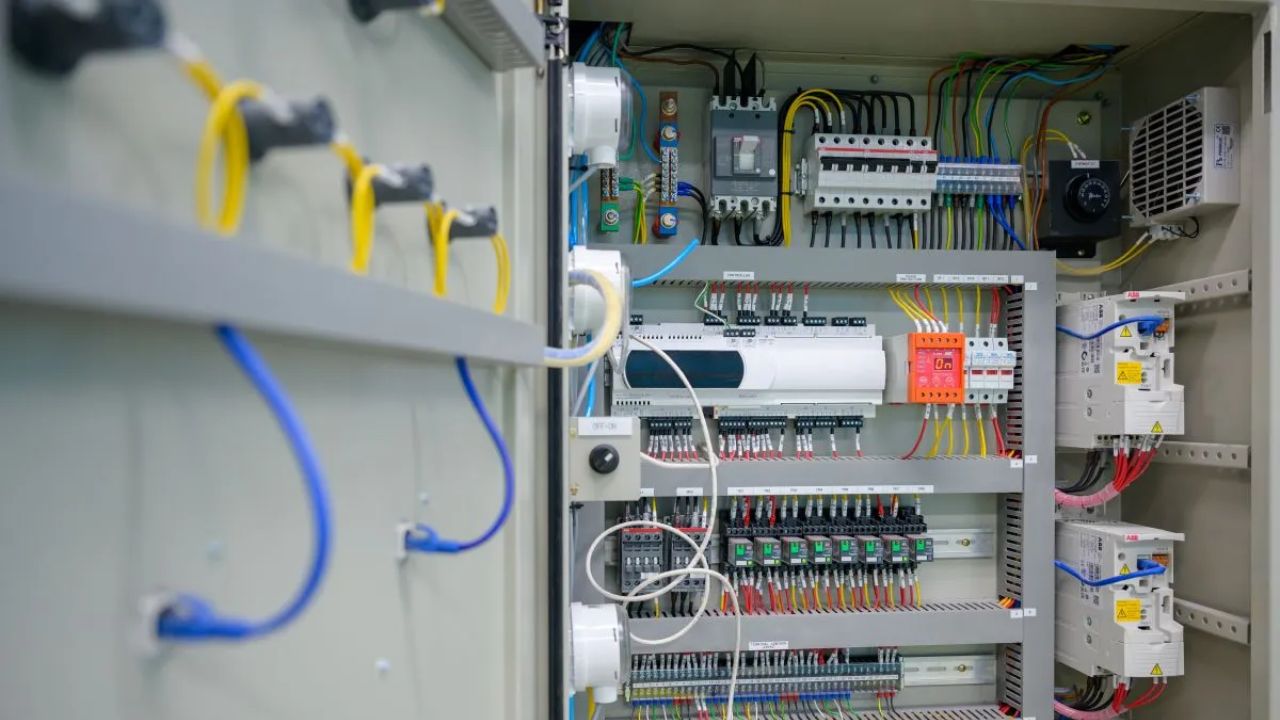

Industrial Automation and Control Systems: For example, PLC control cabinets and motor control centers in factory workshops. Most factory indoor environments are relatively controllable and do not have strong corrosive media. These cabinets require high-strength to bear a large number of heavy components. High-quality powder coating is sufficient to provide protection.

Heavy Machinery and Enclosures: Such as control boxes for injection molding machines, enclosures for laser cutting machines, electrical cabinets for machine tools, etc. These devices may generate vibrations or need to withstand accidental physical impacts. The high strength and excellent welding properties of mild steel enable the fabrication of very sturdy and highly customizable heavy-duty protective structures.

Часто задаваемые вопросы

Is Stainless Steel Always Better than Mild Steel?

No. Stainless steel is not always superior to mild steel. Usually, in harsh environments (wet, corrosive), with no maintenance required or for extremely long lifespans, and under strict hygiene standards for high-end products, stainless steel is your better choice. However, when cost is limited, environmental conditions are controllable, physical strength requirements are high, and complex customized designs are needed, mild steel is undoubtedly your best option.

Which Is More Durable: Aluminized Mild Steel or Stainless Steel?

Generally speaking, stainless steel is undoubtedly more durable, but aluminized mild steel is a compromise between cost and performance in some environments. If you seek the lowest maintenance and absolute durability, you can choose stainless steel. If the corrosion is not severe, the budget is limited, and regular inspections are acceptable, then aluminized mild steel is an economical and practical option.

How Can You Easily Tell Them Apart?

The simplest method is to use an ordinary magnet to attract the material. Mild steel is strongly adsorbent, and stainless steel may have no magnetism at all or only weak suction. However, a few stainless steels are also magnetic. Therefore, your most reliable method of identification is to check the material warranty or use a professional detector.

Заключительные мысли

As a manufacturer with many years of production experience, KDM can provide you with various types of electrical enclosures in different materials, with different features and installation methods. We can also provide you unique customized solutions to meet your different application scenarios. The enclosures are made of robust materials and with advanced production processes. Please feel free to связаться с нами to start your customized production.