KDM—Your Trusted Manufacturer in China

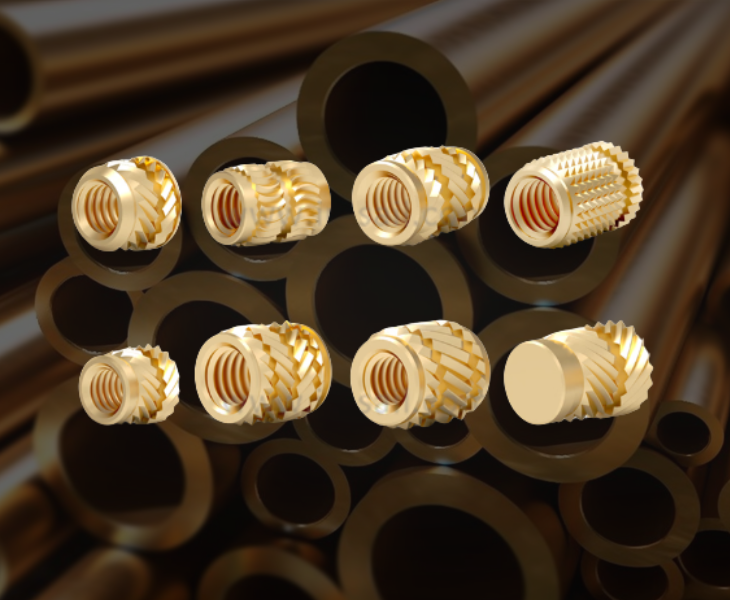

Our brass inserts product can be used in various fields, such as hardwood, plastic, metal, and 3D printing. The brass inserts can provide metal threads and anti-slip features for plastic materials. As for the wood materials, they can prevent cracking and loosening so that the wood will last for long-term use. For the metal materials, the brass inserts can improve wear resistance and are easy to maintain.

KDM helps you customize the brass inserts. From thread type, knurl pattern, to the length, different customizations have different options. Whether you need press-fit inserts for ABS plastic, heat-set inserts for 3D printed parts, or threaded inserts for wood furniture, just tell us your requirements, our professional team members will help you choose the most suitable option.

You can always trust the quality of KDM’s brass inserts. Our products strictly follow the ISO 9001 quality management system, making sure every insert has high precision and stable performance. Each of our inserts is made of high-quality brass material that meets the GB/T 2059 national standards, ensuring its corrosion resistance. Don’t hesitate to contact us if you are interested.

Best Selling Brass Inserts By Threaded

There are two most basic methods to divide brass inserts in structure according to KDM’s standard: brass non-threaded inserts and brass threaded inserts.

Brass threaded inserts typically have internal or external threads to achieve a secure threaded connection. The processing is more complicated.

OEM/ODM customization supported, hex nut of head type, the diameter is M6-M20, and the minimum order quantity is 1000 pieces.

This can be used to connect, fasten, and decorate. Fit for cabinet, sheet metal, motors, building decoration, etc. 15-20 days delivery time.

Made of premium brass C3604 material, fit for heavy industry, mining, water treatment, etc. The

minimum order quantity is 1000 pieces. 3-15 days delivery time.

Provide customization and samples, we have the certification of ISO SGS ROHS. Eco-friendly and typically used for the plastic insert.

Supply free samples, finished by black oxide, OEM/ODM supported. Mainly applied in building, heavy industry, water treatment, healthcare, etc. The minimum order quantity is 10000 pieces.

Finished by polished, 7-10 working days delivery time. One-stop shopping, high quality, supply material, and test reports.

CNC machining, OEM/ODM supported, 17-24 working days delivery time, mainly applied in cutting tools and fastener tools.

Self-locking structure to prevent thread loosening, matches with refrigeration equipment, two-year warranty. OEM/ODM supported.

Best Selling Brass Inserts By Non-Threaded

Brass non-threaded insert parts don’t have any thread processing on their surface. They have a simple structure and a low manufacturing cost, usually used for positioning, isolation, conduction, or as structural parts.

-

Long Brass Pillar

Long Brass PillarMade of HPB59 brass, finished with zinc yellow-chromate plated. 100% quality inspection of each product. The minimum order quantity is 200 pieces.

-

Brass Plug-In Pin Inserts

Brass Plug-In Pin InsertsCustomize the size and color, comply with IEC standards, high-quality and precision processing to ensure the stability, reliability of the connection.

-

SMT Brass Dowel Pin

SMT Brass Dowel PinOEM/ODM supported, ISO ROHS certification, used for the new energy industry, medical instruments, electronics, etc. 3-15 days delivery time.

Функции

High-quality brass inserts made just for you. Check out the key features below.

Made of brass, resists rust and corrosion, especially fit for wet and outdoor environments.

Suitable for heat-set, ultrasonic, press-fit, or self-tapping installations.

Available in straight knurl, diamond knurl, or hexagonal body to enhance torque resistance.

Used in electronics, home appliances, automotive interiors, 3D printing, and industrial equipment.

Special Finishes and Platings

KDM provides the special finishes and platings for the brass inserts. We have various surface treatments according to the different requirements. Heat treating can be used to strengthen the structure. In-house plating and Anodizing can be used to improve the appearance and prevent corrosion. Knurling can prevent slipping and provide a better grip. If you are interested, send an inquiry to us.

Brass Threaded Insert Types We Can Offer

As the most basic type of brass inserts, threaded inserts also have a wide range of types. Different threads have completely different applications.

- Chevron Threaded: Used in plastics where high rotational and tensile strength is required

- Tapered Threaded: Commonly used in sealing applications, such as fluid pipes or anti-loosening fasteners

- Multi-Start Thread: Suitable for quick assembly and high-efficiency installation

- Mold-in: High firmness requirements, suitable for the injection molding process (non-removable)

- Press-in: For thermoplastics, cork, 3D printed parts, and more

- Expansion: Structural connections that are sensitive to vibration or loosening, such as furniture and aluminum profiles

Give us your requirements, and we will help you choose the best option.

Get Custom Brass Inserts Fast

KDM always puts your needs in the first place. We manufacture custom brass inserts to your requirements. From design to delivery, we partner with you to bring your ideas to life.

- Every insert is optimized for your product

- From small runs to high orders, we can provide a stable supply

- Quick delivery and fast lead times

- Our expert team works with you from the first to the last

Brass inserts are small metal components used to connect materials, typically between plastics, wood, and soft metals.

Yes, KDM specializes in customizing brass inserts based on your ideas or drawings.

We use high-quality brass like C3604, H59. Compared to the general brass, it has higher cutting performance and dimensional stability, suitable for high precision parts.

Normally, 7–15 days for regular orders. Urgent or custom projects can be expedited.

Of course, we will give you the recommendations for the installation(heat, press-in, ultrasonic).