The selection of raw materials is directly connected to the product performance, service life, and even entire cost. Aluminum alloy is one of the most commonly used metal materials in the manufacture industry, equipment industries, and engineering projects. This article will introduce the basic information and core advantages of aluminum alloys, helping you better understand and select appropriate aluminum alloy materials.

What is Aluminum Alloy

Aluminum alloy is a type of metal material that consists of aluminum as the primary component with the addition of one or more alloy elements. Its aluminum content typically constitutes over 85% of the alloy. Pure aluminum features high electric and thermal conductivity, and is resistant to corrosion. But its mechanical strength is relatively low, and is easy to deformation, which means the pure aluminum cannot meet the high load requirement. Through adding different metal components to achieve alloying, the core performance of aluminum materials can be improved.

Key Properties of Aluminum Alloy

The aluminum alloy is widely used in the industry due to its balance between the enhanced performance, high machinability, and others. Learning its core properties is helpful for you to make a wise purchase decision.

出色的强度重量比

One of the most significant advantages of the aluminum alloy is its high strength-to-weight ratio. This means within equivalent strength requirements, the density of aluminum alloy is approximately one-third of the steel material. The lightweight feature of aluminum alloy is important for applications that need to decrease the overall weight. Using aluminum alloy as the raw material not only decreases structural loads to reduce costs of transportation and installation, but also improves the entire energy efficiency and system performance.

高耐腐蚀性

Compared to ordinary carbon steel, the aluminum alloy is more suitable to be used in outdoor, wet environments, and the chemical or food industry, due to its high corrosion resistance. When exposed to the natural environment, the aluminum alloy will form a dense protective layer caused by oxidation. This dense layer supports isolating materials from air, dust, or moisture, thereby preventing further corrosion. If your project has higher demands on the corrosion resistance performance, additional surface processes such as anodizing are helpful to extend the service life of aluminum alloys.

Thermal and Electrical Conductivity

The aluminum alloy also features good thermal conductivity, which is just lower than copper materials. Due to this performance, the aluminum alloy is widely used for heat exchangers, radiators, and other similar applications. In addition, the aluminum alloy also offers good electrical conductivity, making it suitable for busbars, cables, and conductive components. Aluminum enclosures are helpful to dissipate heat in time, preventing failures or damage of electrical equipment caused by overheating.

Excellent Machinability

Aluminum alloy offers excellent machinability and formability to adapt to various different manufacture processes, such as extrusion, rolling, casting, and CNC machining. It supports being processed into complex cross-sections or high-precision components based on the excellent processibility. This property also reduces the wear level of tools, not only extending their service life, but also enhancing production efficiency. For large-scale projects, aluminum alloy significantly shortens the processing cycle, thereby saving your investment on equipment operation and labor costs.

Recyclability and Sustainability

As a 100% recyclable material, the excess aluminum alloy material can be recycled and reused during the manufacturing process. The value of recycled material can reach 80% or higher of the price of primary aluminum, which means it can directly offset raw material costs. In addition, for some markets like the EU and North America, certain recycled content is necessary to obtain the green pass. The recyclability of aluminum alloys also help you achieve the goal of low-carbon manufacturing and sustainable development.

低成本

Even if the purchase cost of some high-performance aluminum alloys is relatively higher than common steel materials, the aluminum alloy offers significant advantages on the total lifecycle cost. It is easy to maintain and features a long service life to reduce your maintenance costs. For large-scale projects, the aluminum alloy supports high production efficiency to accelerate the project lifeline, thereby helping you take on more business. It offers a balance between stable operation and cost control to achieve high economic efficiency.

Classification of Aluminum Alloy

Wrought Aluminum Alloy

Through plastic processing methods such as rolling, extrusion, and forging, aluminum alloy can be formed into wrought aluminum alloys. This type of aluminum alloy material typically exists in forms like plates, profiles, tubes, and rods, which is the most widely used aluminum alloy in the industry. The wrought aluminum alloy features dense structures to offer stable mechanical properties, making it suitable for applications that demand high strength, toughness, and ductility. If your project involves high requirements on quality and safety such as electrical equipment, wrought aluminum alloys are a good choice to ensure consistency and reliability.

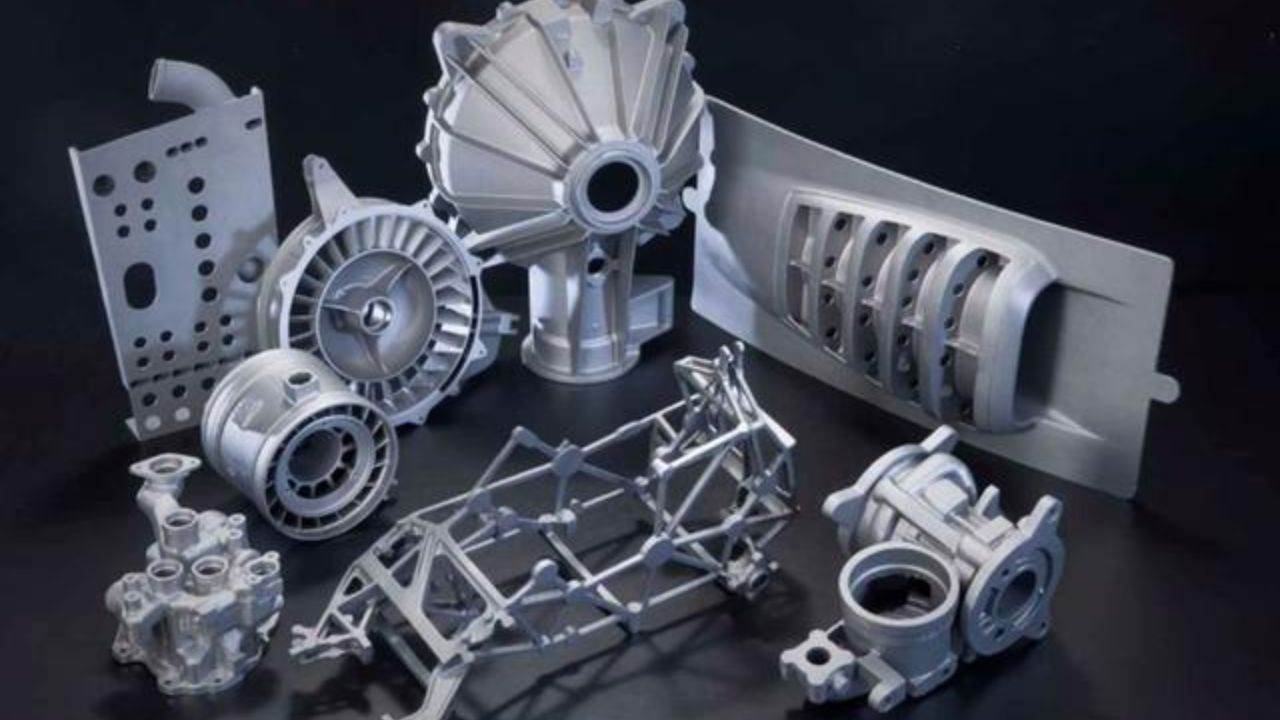

Cast Aluminum Alloy

Unlike wrought aluminum alloys, the cast aluminum alloy is produced by pouring molten aluminum alloy into molds. It is suitable for components with complex shapes or high structural integration, such as engine housings, pumps, valve bodies, and other supporting parts. The cast aluminum alloy offers good flowability to adapt to various different molds or complex structures. Compared to wrought aluminum alloys, the strength of cast aluminum alloys is lower, but it features advantages on the structural complexity and manufacturing costs.

Manufacturing Processes for Aluminum Alloy

The performance of aluminum alloy is not only determined by its chemical composition, but also connected to the manufacturing process. Different processes directly affect the final features of aluminum alloys, including strength, surface finish, and other performance. The following are commonly used processes to handle aluminum alloys.

- Extrusion: With the help of high pressure, the extrusion process uses molten aluminum alloys to throw a certain mold, forming continuous extrusions with a fixed cross-section. This process achieves one-piece forming for complex structure, which can enhance the stability of final products by reducing welding point and assembly steps. It offers a high material utilization rate, and is especially suitable for manufacturing 外壳.

- Rolling: The rolling process is the main method to produce aluminum alloy sheets and strips, which are widely used for structural coverings and other enclosure products. This manufacturing process supports precisely controlling the thickness of products, meeting different project demands. It offers high surface finish to ensure consistency and is suitable for subsequent stamping, bending, and welding.

- Casting: When your project involves components with complex structure, numerous internal passages, and high assembly costs, the casting aluminum alloy is an ideal choice. Casting processes including gravity casting, die casting, or others, are suitable for mass production due to their significant cost advantages. This process also achieves high structural integration to reduce part count, ensuring reliable and stable components. It is also widely used for functional housings and load-bearing components.

- CNC Machining: The CNC machining directly determines the assembly precision and consistency of components as the final finishing process. It is typically used to handle small-scale projects or customized components based on its excellent flexibility and high production capacity. If you have high demand on product precision, this process will be helpful.

- Surface Treatment: In the end of aluminum alloys manufacturing, surface treatments are typically important. They are directly connected to the service life, maintenance cost, and brand image. Common surface treatments of the aluminum alloy include anodizing, spraying, and electrophoresis. After anodizing process, the corrosion resistance and electrical insulation performance of aluminum alloys can be improved. While if you have more demands on aesthetics, adding coatings for the alloy is also helpful to enhance its environmental adaptability.

Applications of Aluminum Alloy

建筑业

Aluminum alloy used in the construction industry offers high corrosion resistance to adapt to the outdoor environments. It is more easy to maintain than common coatings to decrease the subsequent maintenance costs. In addition, the lightweight feature of aluminum alloys can also reduce the hoisting and foundation load requirements. Based on the extrusion molding process, the aluminum alloy can be formed into various shapes to meet different requirements, achieving an integration of structure and decoration.

New Energy Vehicles

The new energy vehicles typically have high demands on both range and safety, and their battery system is sensitive for weight and heats. The aluminum alloy offers excellent lightweight design to reduce the energy consumption, thereby extending the driving range. Based on the industry experience, every 10% weight reduction lowers energy consumption by 6%- 8% to enhance range time. The aluminum alloy used in automotive industries is also suitable for battery heat management due to its high thermal conductivity, achieving highly efficient heat dissipation.

Electrical Industry

Electrical equipment usually generates a large amount of heat due to the continuous operation. It also has high demands on corrosion resistance level, especially the 户外电气外壳. Unlike steel materials, the aluminum alloy is resistant for corrosion, making it suitable for outdoor substation and distribution systems. Aluminum alloy also features high thermal conductivity to reduce localized hot spots, preventing electrical failures caused by overheating. This type of material is non-magnetic, which can reduce the risk of electromagnetic interference.

工业设备

The industrial equipment generally employs aluminum alloys to improve production efficiency. This type of material offers extreme lightweight to accelerate equipment dynamic response. And its excellent machinability also allows various machining processes to meet different project demands, shortening delivery cycles. If you need to manufacture customized products, the extrusion process also helps you reduce the entire costs.

照明设备

During the manufacturing process, aluminum alloy is used as the shell of the lighting fixtures. Aluminum alloy is lightweight and has sufficient strength to resist impact. It is often applied in LED Linear High Bay lights in the lighting industry.

Aluminum Alloy vs Other Materials

| Aluminum Alloy | 碳钢 | 不锈钢 | 铜 | |

| Density(g/cm³) | 2.7, the most light one | 7.85 | 7.9- 8.0 | 8.96 |

| Specific Strength(Strength/Density) | Extremely high | 中等的 | High | Relatively low |

| 电导率 | High, approximately 60% that of copper | Low, ferromagnetic material | Low, high resistivity | Most excellent, international standard good conductor |

| 热导率 | High | Low | Low | Highest |

| 耐腐蚀 | Good, based on oxide film and surface treatment | Terrible, require surface protection | Excellent | Excellent, but is sensitive to ammonia and sulfides |

| Magnetic | None | Ferromagnetism | Austenitic no, such as 304 | None |

| 可加工性 | High, support cutting, extrusion, casting | High, suitable for cutting and welding, but heavy | Low, work hardening, tool sticking, and low efficiency | High, but require specialized tools to prevent sticking issue |

| 可焊性 | Good, require specific processes, and easy to oxidation | Extremely high | Good, heat input must be controlled | Good, offer rapid thermal conductivity |

| Recyclability | Most excellent, and recycled materials feature high value | Good, but the energy consumption during this process is relatively high | 100% recyclable, alloy elements may be lost | 100% recyclable, extremely high value |

| 应用 | Industries that require lightweight design, thermal dissipation systems, electrical enclosures, etc | Construction structures, heavy machinery, bridges and vessels, etc | Harsh environments like chemical vessels, food and medical equipment, high-end kitchenware | Wires, busbars, electronic components, heat exchangers, and more |

常见问题解答

Q: Can Aluminum Alloy be Welded? What are Common Welding Methods Used for Aluminum Alloys?

A: Yes. Common welding methods used for the aluminum alloy include TIG and MIG. The TIG welding method offers high precision and aesthetically pleasing welds, and is suitable for precision thin-sheet welding. While the MIG welding offers a faster speed, which is suitable for thicker materials or long welds. You can choose proper filler wire and shielding gas while also controlling the heat input to prevent distortion and oxidation.

Q: What are the Most Common Aluminum Alloy Grades?

A: In sheet metal fabrication, the most commonly used aluminum alloys are 5000 series and 6000 series. The 5000 series aluminum alloy features high magnesium content, which means it can offer excellent corrosion resistance and good weldability. This alloy is typically used in marine vessels, vehicle bodies, and electronic enclosures. While the 6000 series aluminum alloy contains magnesium and silicon, offering high strength, atmospheric corrosion resistance, and good machinability. It is widely used in high-strength structural components, aerospace frames, and more.

Q: What Factors Should I Consider When Selecting Aluminum Alloy Materials?

A: When selecting aluminum alloys for your project, you should consider comprehensive factors to ensure the material you choose can meet actual demands. For example, you can determine the required strength, corrosion resistance level, and machining requirements based on the actual conditions. The surface treatment is also important to ensure aluminum alloy can be integrated with existing appearance styles.

最后的想法

Aluminum alloy offers higher performance on strength, corrosion resistance, machinability, and others than pure aluminum materials. It is widely used in various industries and suitable for different machining processes. If your project requires aluminum alloy fabrication or have any questions about this material, please feel free to 联系我们 for professional and customized solutions.