Industrial control panels help you manage power and automated processes. The choice between open and enclosed industrial control panels depends on protection, safety, and cost. Engineers and managers can make the right choices by understanding these differences. In this article, you’ll explore each of them and contrast their main features.

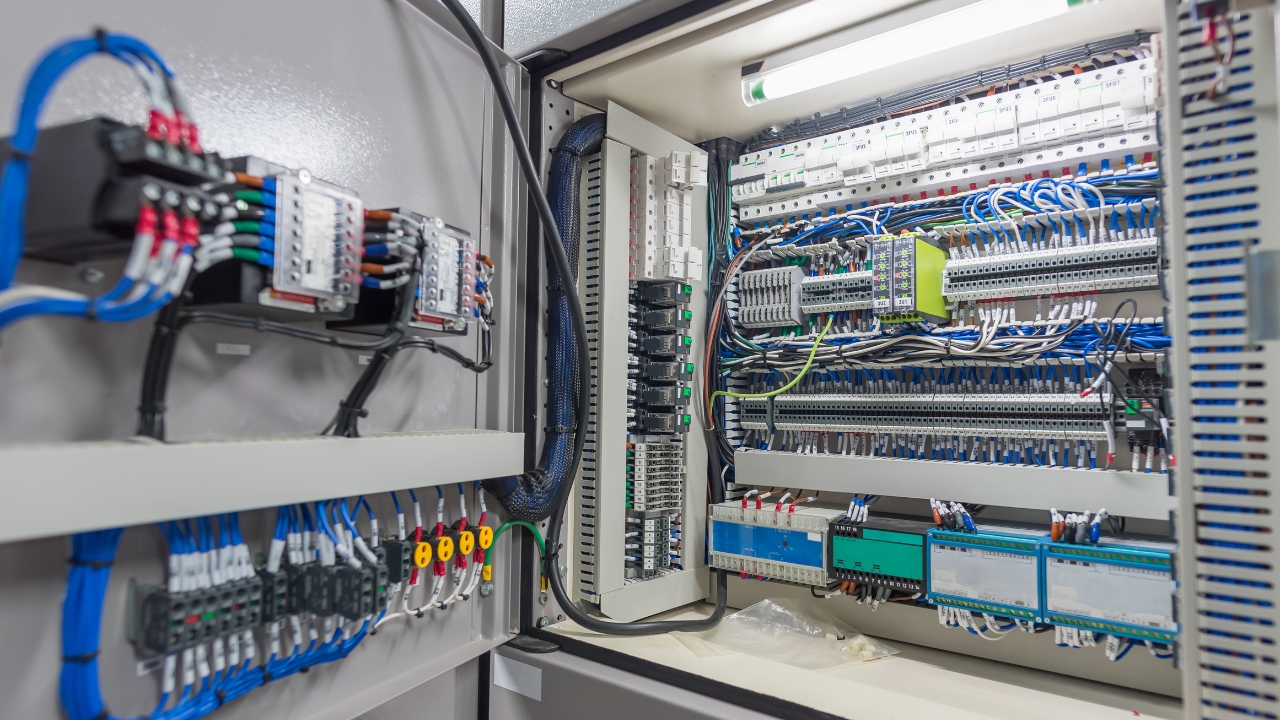

What Are Open Industrial Control Panels?

Open industrial control panels are assemblies in which components such as relays, drives, and circuit breakers are mounted on the back panel without an outer enclosure. These panels will provide you with easy visibility and quick access for maintenance.

They need different enclosure installations to satisfy NEC and UL requirements. These panels are customarily used in bigger enclosures or restricted-access areas. The key features include simplified maintenance and low material costs.

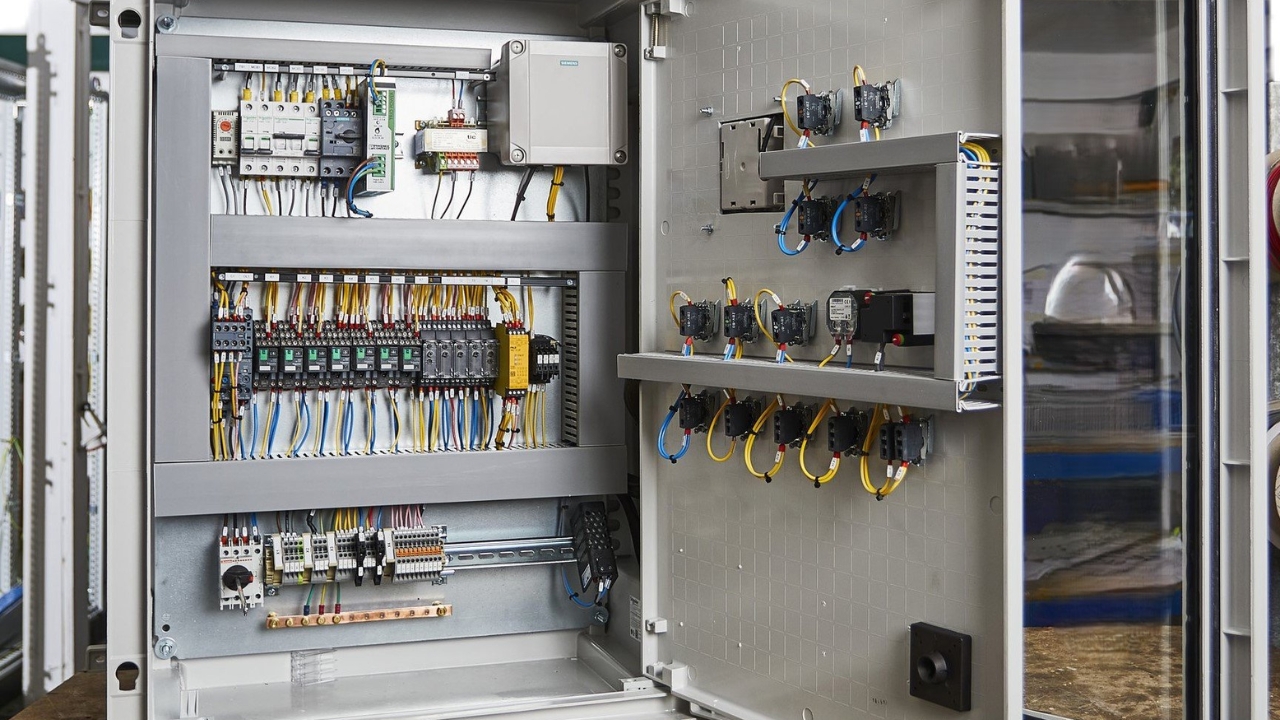

What Are Enclosed Industrial Control Panels?

Enclosed industrial control panels are electrical components housed within a sealed metallic or non-metallic enclosure. The outer cover gives protection against dust, moisture, and accidental contact. The assembled unit is UL‑508A listed as a complete system.

Some of the features that are common to them are lockable doors, cooling systems, and compliance labels. You can use them in situations that need safety, cleanliness, and environmental control.

Difference Between Open and Enclosed Industrial Control Panels

1. 보호 수준

Open control panels offer you limited protection against dust, water, or physical contact. They suit a controlled and clean environment.

On the contrary, enclosed panels offer you complete protection against environmental dangers such as liquids, waste materials, debris, and unwanted access. They often meet NEMA/IP ratings. You can use them in high-traffic or harsh surroundings since the chances of damage and injury are less due to the sealed structure.

2. Safety Standards Compliance

You require separate UL-listed housing with open panels, and they must be proven to have been installed properly according to the Authority Having Jurisdiction (AHJ). Compliance is crucial to protect workers and abide by the requirements of the industry, particularly in public or hazardous zones.

Enclosed panels have UL‑508A certification, which includes shock and fire safety. They are built in a way that they support lockout/tagout practices and eliminate the possibility of accidental contact with the live parts.

3. Installation Complexity

The open panels are easy and quick to fit into the factories where enclosures are already installed. They save you time in assembly and wiring.

Enclosed panels, on the contrary, need extra planning. You must consider sealing, mounting, and ventilation. They also require more time to install and give a more complete, self-contained system, which can be immediately deployed.

4. 사용자 정의 및 유연성

Open panels allow easy modifications and upgrades with visible layouts of the components. Engineers are capable of reconfiguring systems without covering up systems. They provide better manual control and flexibility to projects that require frequent adjustments or expansion.

Enclosed panels have their flexibility, but for the alteration, you have to open up a unit, which may involve switching off the power.

5. 비용 고려 사항

Open panels in China typically cost you around US$30-$100 per panel without considering enclosure costs.

Enclosed panels can cost US$80 for basic IP65 models and up to US$1,000 or more, depending on size, IP/NEMA rating, and certification. You need a higher upfront investment that includes housing, seals, and certified safety testing. Long-term value comes from reduced compliance issues and extended durability.

6. 환경적 적합성

Open panels are ideal in a clean indoor environment where there is consistent temperature and little dust. They might fail to be compliant with environmental sustainability standards such as RoHS or ISO 14001.

You can use enclosed panels for compliance and harsh conditions. They may be constructed using RoHS-compatible components, energy‑efficient designs per ISO 50001/14001, and moisture-proof, dust-free, and chemical-proof sealed housings.

7. Maintenance and Accessibility

You need less maintenance time for open panels, as faults are easier to detect visually. They offer fast and tool-free access to components.

Enclosed panels must be unlocked and have safety precautions before being able to view internal sections. This is time-consuming, and it enhances the safety of workers. They are more tedious during service, but they help you to prevent unauthorized access and accidental tampering of the system.

8. 응용 프로그램

Open Industrial Control Panels:

You’ll find these in internal machine control within cabinets. They would work best in R&D laboratories and educational training installations. They are also applicable in pilot lines of production. These are suitable when working in test stations and clean room automation systems.

Enclosed Industrial Control Panels:

You would apply them in food and beverage or pharmaceutical plants that needed washdown. They are ideal for outdoor pump stations and water treatment plants. They may also be utilized in heavy production centers and at chemical plants. The systems can guarantee longevity in extreme or dangerous environments.

Get Top-notch Open or Enclosed Industrial Control Panels from KDM Steel

Are you looking for flexible open panels or highly protected enclosed enclosure panels? KDM Steel would provide finely tuned solutions to your needs. You will obtain certified quality, expert customization, and quick delivery. Contact KDM Steel today and find out what we can do to make your project a success.

결론

The choice between Open vs. Enclosed Industrial Control Panels will be determined by your surroundings, safety level, and cost. Open panels are appropriate in clean and controlled environments, whereas the enclosed panels perform well in harsh and demanding environments. These two enclosures are very important in automation and manufacturing industries. When you want compliant, reliable, and cost-effective solutions, contact KDM스틸, your preferred partner in the manufacturing of control panels.