Condensate tanks store the condensate from steam in boilers and industrial process systems, assisting in reusing heat recovery water and maintaining stable boiler operation in demanding industrial facilities. These tanks help engineers, managers, and maintenance teams to save energy and reduce corrosion. This article discusses what a condensate tank is and the purpose of the tank, its components, how it works, and its selection instructions.

What Is a Condensate Tank?

Condensed steam released by heat exchangers and boiler turbines is collected in a condensate tank. の tank serves as a collection and stabilization point. It allows for the separation of flash steam from the liquid condensate and provides a controlled reservoir of hot feedwater for pumps. This process stabilizes the temperature of the feed water and safeguards the equipment, in addition to enhancing thermal efficiency. To minimize the fuel demand for water and the boiler load, you should install a condensate tank.

Main Components of a Condensate Tank Assembly

· Tank Vessel & Construction

の tank vessel contains high-temperature condensate either at atmospheric or low-pressure conditions. It is comprised of carbon or stainless steel, which is designed to become thermally expansive, inhibit corrosion, and withstand pressure with the help of welded or fabricated construction.

· Inlets, Outlets & Internal Piping

The condensate of steam and process equipment is gathered in inlets at a controlled velocity. Internal piping causes less turbulence and flashing, and the outlets are the same flow to the condensate pumps.

· Level Controls and Instrumentation

Level switches and transmitters perform continuous monitoring of the amount of condensate. The controls are used to switch on pumps, activate high/low alarm, and maintain a safe supply of feedwater to boiler/deaerator systems.

· Condensate Pumps and Pump Skids

Passing of condensate to boiler feed water/deaerators is done by centrifugal pumps. The pumps, the motors, the valves, the strainers, and the controls are included in pump skids to ensure reliability and redundancy in use.

· Vents, Reliefs, and Accessories

Vents release flash steam and non-condensable gases. Relief valves are placed to avoid the overpressure of the tank. Strainers, manways, and ports are also accessories that enhance safe operation and maintenance.

| Component | 関数 |

| Tank Vessel | Stores high-temperature condensate; carbon/stainless steel for pressure and corrosion resistance. |

| Inlets & Piping | Directs condensate, reduces turbulence and flash steam, and ensures steady pump flow. |

| Level Controls | Monitors volume, operates pumps, triggers high/low alarms. |

| Pumps & Skids | Transfers condensate; skids integrate pumps, valves, strainers, and controls. |

| Vents & Reliefs | Releases flash steam and gases; relief valves prevent overpressure; supports maintenance. |

Types of Condensate Tanks and Systems

· Open (Atmospheric) Condensate Tanks

Open condensate tanks are actually atmospheric pressure condensate tanks that collect condensate in several steam traps. They divided flash steam using natural pressure drop. There are flow level instruments that control the tank and overflow protection. Normal design takes into consideration the expansion (thermal), corrosion allowance, and temperatures up to 120-150 °C.

· Pressurized or Closed Condensate Systems

Pressurized tanks keep the condensate at a constant pressure in order to decrease flashing. They run between 2 and 10 bars based on the boiler returns’ needs. The system is protected by relief valves, vents, and level controls. High-pressure boiler feed is supported by pressure tanks, which can easily deliver it without deaeration.

· Condensate Receiver Units vs. Boiler Feed Units

Condensate collected by process equipment and traps is then collected to feedwater by receiver units. The boiler feed units comprise storage and pumping, incorporating a centrifugal/ multistage pump, valves, and instrumentation. The choice is determined by the pressure in the system, the load of condensate, and the type of boiler.

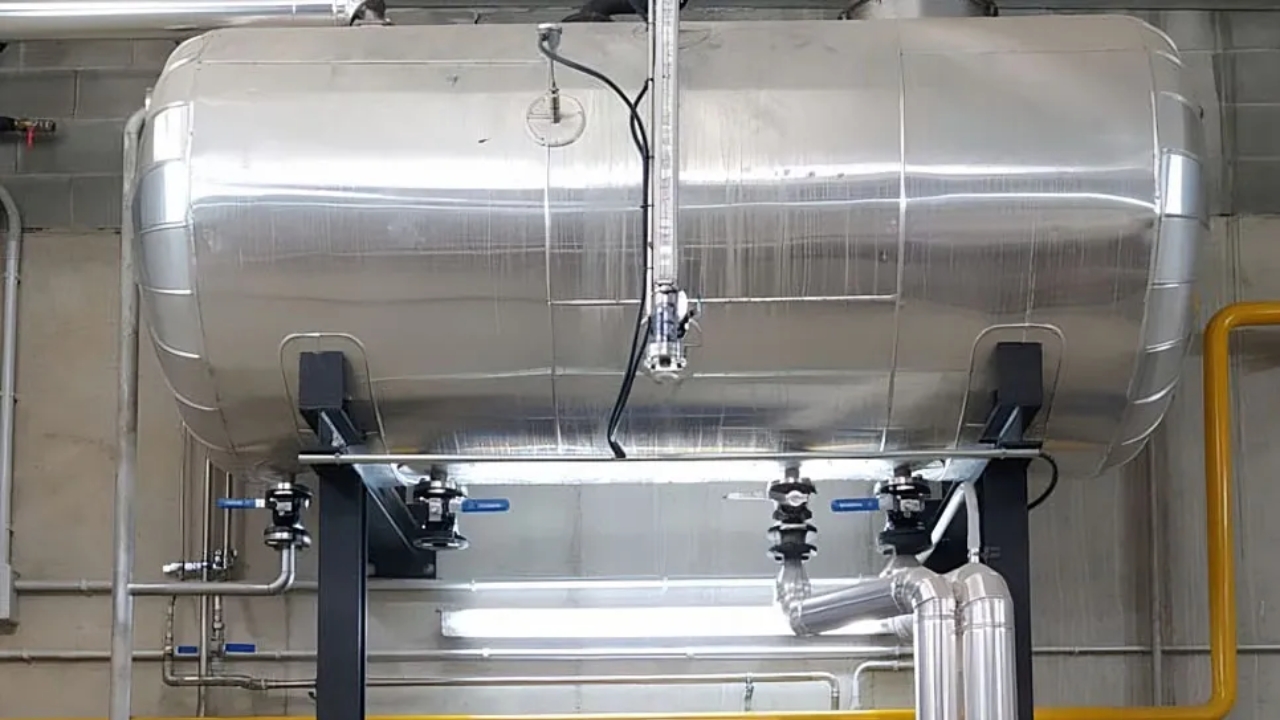

· Orientation, Materials & Custom Designs

Tanks can be vertical or horizontal, depending on the layout of the sites and the hydraulics of the flow. High temperature and corrosion-resistant high temperature alloys are made of carbon steel, stainless steel, or duplex. Custom units combine vents, reliefs, level controls, and connect the pump to suit the operational requirements of the plant.

How a Condensate Tank Works: Step-by-Step Process

· Flow Path from Steam System to Condensate Tank

Condensate releases traps and process equipment that are controlled by pressure and temperature. It goes into the tank via the inlet piping and does not maintain adequate velocity in order to inhibit flashing, erosion, and water hammering during transfer.

· Filling, Level Control & Pump Operation

Continuous monitoring of condensate volume is done by level sensors. High-level triggers alarms, and bottom-level activates pumps. Pumps supply condensate to boiler feed water or deaerator systems to ensure a constant supply of feed water.

· Handling Flash Steam and Venting

Flash steam is created when the hot condensate is introduced into the tank at reduced pressure. The vents and separation devices will discharge the steam and eliminate the accumulation of pressure, and improve the efficiency of liquid recovery.

· Integration with Feedwater and Boiler House

Feedwater pumps and boiler inlet lines are directly connected to condensate tanks. The control panels and pump skids match boiler demand to delivery, being thermally efficient, stable in pressure, and providing equipment protection.

Key Design Parameters and Sizing Guidelines

· Storage Capacity and Retention Time

Compute tank volume with regard to rate of condensate return, maximum load, and retention time. Retention provides separation of flash steam and eliminates cavitation of the pumps in the working process.

· Temperature and Pressure Ratings

Design the tank and piping for maximum condensate temperature and operating pressure. Take thermal expansion, system pressure, and flash steam parameter into consideration.

· Pump Flow, Head & NPSH Requirements

Choose sufficient flow and total head pumps. Make sure that Net Positive Suction Head (NPSH) is at least the boiler feedwater or process system requirement in order to avoid cavitation.

· Level Control Strategy and Instrumentation

Control the operation of pumps by using continuous level transmitters, high/low level alarms, and interlocks to avoid overflow or dry run situations. Interoperate with PLC or DCS.

· Insulation, Heat Loss & Energy Considerations

Thermal insulation should be applied to reduce heat loss in the tank and piping. Determine the energy retention to sustain condensate temperature to be used as boiler feed or process make-up.

Installation Best Practices for Condensate Tanks

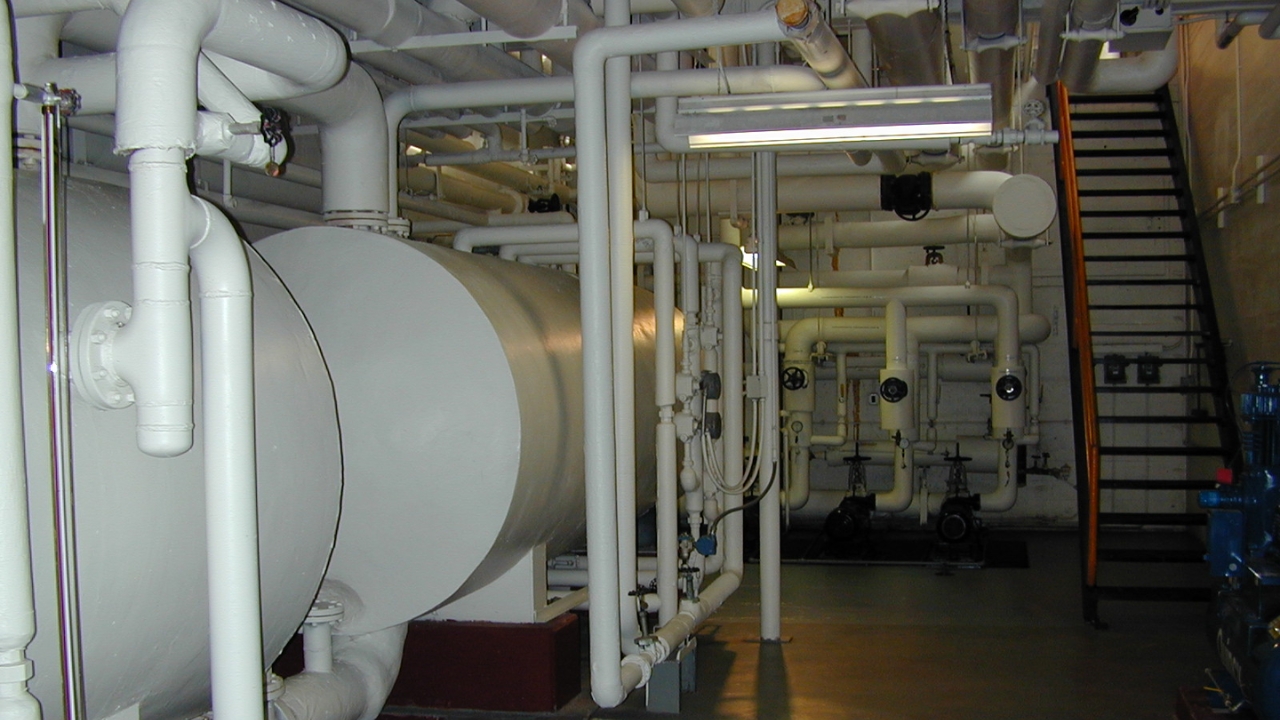

· Location and Layout in the Boiler Room

Place condensate tanks near steam traps and boiler feed water. Make sure that there is a minimum length of pipe, an ideal slope, and easy access to maintenance.

· Piping, Valves & Vent Connections

Install Isolation and check valves. Use isolated and sized inlet/outlet piping. Install vents and pressure relief devices in order to manage the flash steam safely.

· Support, Access & Drainage

Tank supports gravity and thermal expansion. Provide drain connections, walkways, and access to inspection of routine cleaning.

· Commissioning and Start-Up Checks

Check the integrity of the tanks, instrumentation, and the functioning of the pumps. Examine and check all valves, vents, and drains. Pressure and leak tests are to be performed first.

Common Problems with Condensate Tanks and How to Fix Them

· Overflowing or Flooded Condensate Tanks

When the level controls fail or are delayed in pump operation, the overflow will occur. Check level sensors, calibrate instruments, and check pump interlocks to avoid flooding. Vent and drain capacity is to be proper.

· Pump Cavitation, Noise & Vibration

Cavitation is caused by low NPSH or high suction velocity. Modify inlet conditions of the pump, alleviate pipe resistance, and check flow rates. Install vibration dampers and keep the pumps on course.

· Water Hammer & Flash Steam Issues

Water hammer and flash steam are a result of the rapid flow of condensates or a drop in pressure. Stabilize flow and pressure using appropriately sized piping, flash separators, and air removal devices.

· Corrosion, Leaks & Tank Failure

Corrosion is caused by acidic condensate or the ingress of oxygen. Use corrosion-resistant materials, carry out the treatment of the chemical, check the welds, and replace or repair the damaged parts before they break down.

Typical Applications and Industry Use Cases

· Power Generation and Cogeneration Plants

High-temperature condensate in turbines, heat exchangers, and steam headers is recovered in condensate tanks. They keep the feedwater hot, minimize the makeup water, and guard the boilers and turbines in constant use.

· Refineries, Chemical & Petrochemical Facilities

Condensate is collected by tanks that are connected with reactors, heat exchangers, and steam tracing systems. They reduce wastage of energy, eliminate corrosion, and assure a good supply of feed water to high-pressure process boilers.

· Pulp & Paper, Food & Beverage, and Pharma

Variable loads, such as digesting, sterilizing, and process steam systems, are dealt with by condensate tanks. They assist in thermal recovery, scaling prevention to equipment, and the result of constant water quality in the processes.

· Commercial Buildings, Hospitals & Campuses

Commercial buildings, healthcare facilities, and campuses use these condensate tanks in their 空調設備 and sterilization systems to ensure reliable condensate return from the distributed equipment. It will improve the overall efficiency of the heating system.

How to Choose the Right Condensate Tank for Your System

· Assessing Your Steam Load and Condensate Return

Calculate the maximum and average condensate boiler and equipment process returns. Size the tank volume and pump capacity by calculating retention time and flow rates.

· Matching Tank Type to System Design

Depending on the boiler pressure, flash steam control, and plant layout, either open or pressurized tanks are used. Plugging with the systems and process requirements.

· Key Selection Criteria and Checklist

Examine material, pressure rating, temperature rating, corrosion allowance, instrumentation, pump integration, vents and accessibility. Ensure that safety standards and the code of industry are adhered to.

· Questions to be asked to Tank Manufacturers and Integrators

Confirm tank pressure rating, material suitability, control incorporation, pump dimensioning, maintenance instructional guidelines, and customization. Before buying, ensure that there is installation support, a warranty, and a service agreement

よくある質問

What is the difference between a condensate tank and a condensate pump?

A condensate tank stores condensed steam and separates flash steam. The condensate, which is stored, is pumped into the boiler or feedwater system by a condensate pump.

Can I run my boiler without a condensate tank?

Yes, although it raises the energy loss, amount of water used, and also causes pump cavitation and boiler damage. The condensate tank increases the efficiency and reliability of the system.

How do I know if my condensate tank is properly sized?

Determine peak condensate return, retention time, and pump capacity. There is level stability, reduced flashing, and the delivery of safe feedwater, which is an indication of proper sizing.

What temperature should the condensate be in the receiver tank?

The condensate must be kept at a temperature between 90 and 110 °C to ensure thermal efficiency, and corrosion is prevented.

When should I choose a stainless steel condensate tank instead of carbon steel?

ステンレス鋼 (e.g., 304 or 316 grades) should be used in high-temperature, highly acidic, or corrosive condensate to avoid corrosion and enhance service life. Using carbon steel would be best for clean and treated condensate in a standard heating system.

Get your Customized Condensate Tank from KDM Steel

KDMスチール designs condensate tanks for high-temperature, high-pressure industrial applications. With our tanks, you have the best recovery of condensate, corrosion resistance, and no problem with integration into your boiler and feedwater systems. Contact us and tell us about your needs, and get a solution that fits your plant perfectly in terms of efficiency and reliability.