The electrical enclosure plays an important role in protecting electrical equipment and ensuring safety in hazardous environments. Can the electrical enclosure prevent internal explosions? This has become an important issue for many industries. This article discusses explosion-proof enclosures features, explosion isolation principles, and applications. Hope this article can help you choose an electrical enclosure suitable for hazardous environments.

Can Electrical Enclosures Prevent Internal Explosions?

Standard electrical enclosures cannot prevent internal explosions. They are usually used to prevent the invasion of external solid objects and liquids. The common ratings for standard electrical enclosures are IP and ネマ. But certified explosion-proof enclosures can safely contain and control internal explosions, preventing them from igniting hazardous external environments.

For the electrical enclosures in hazardous areas, completely eliminating the possibility of internal ignition sources is often not achievable. The explosion-proof enclosure in the hazardous area allows explosions to occur inside the subject. However, explosion-proof electrical enclosures can strictly limit the destructive consequences of the explosion to within your enclosure.

The explosion proof enclosure design adopts extremely strong structural strength, precise explosion-proof joints, and safe fastening and sealing. The explosion-proof enclosure is very similar to the flameproof enclosure. A sturdy enclosure can withstand the explosive pressure generated during the explosion of flammable mixtures without undergoing permanent deformation or rupture.

What Is An Explosion Proof Box or Enclosure?

The primary and fundamental purpose of an explosion-proof electrical enclosure is to safely withstand the explosion pressure and prevent the spread of explosion flames and high-temperature gases into the interior of your enclosure. Rather than preventing sparks or explosions inside electrical equipment. Therefore, the more professional name for an explosion-proof enclosure is a flameproof enclosure (Ex d), which can more accurately describe its function.

The working principle of flameproof enclosures is based on two core functions: the structural strength of your flameproof enclosure and the explosion-proof joint.

The wall thickness, material and structure of the explosion-proof electrical enclosure are precisely calculated and tested. It can withstand the maximum explosion pressure generated by the internal specific flammable gas explosion and multiple impacts. And it is also necessary to guarantee that it does not permanently deform or crack.

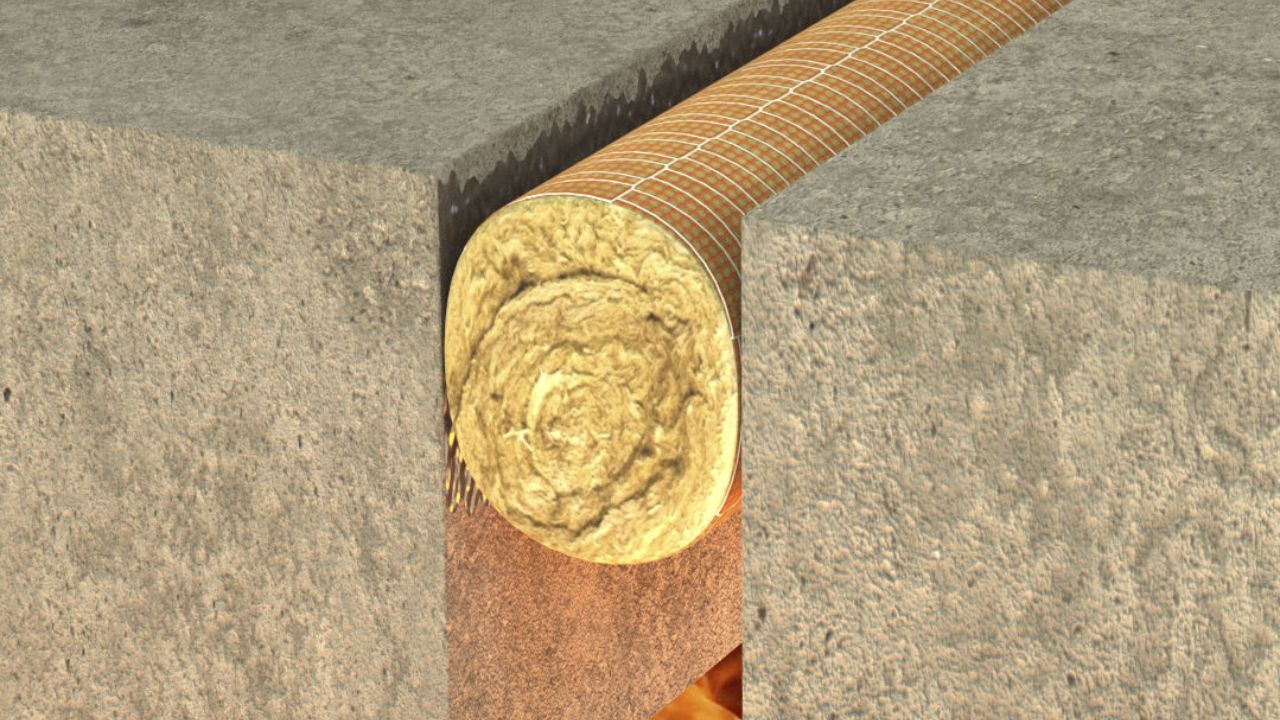

The explosion-proof joint is the most ingenious part of the explosion-proof technology. The cover of the explosion-proof enclosure and the box body, as well as the shaft and the shaft hole, are not completely sealed. Instead, they are designed with precisely defined gaps, which constitute your explosion-proof joint.

Besides the explosion-proof enclosures, explosion proof protection also includes other methods.

Intrinsic Safety (Ex i): This requires you to limit the circuit energy at the source, so that it is impossible to generate an effective spark. This explosion-proof method does not require a sturdy enclosure.

Increased Safety (Ex e): This method mainly emphasizes improving the safety of the equipment to prevent the generation of sparks, arcs or excessive temperatures during normal operation.

Pressurized Enclosure(Ex p): This enclosure allows you to continuously fill the interior with protective gas, keeping an internal pressure higher than the external pressure. This can prevent dangerous gases from entering.

Key Features of Explosion-Proof and Flameproof Enclosures

Structural Strength

Heavy and Sturdy Enclosure: Explosion-proof enclosures are mostly made of materials such as アルミニウム そして ステンレス鋼. The wall thickness of enclosures needs to be sufficient to withstand the maximum explosion pressure generated by an internal explosion. The pressure that the explosion-proof enclosure can withstand is usually more than 1.5 times the reference pressure. It can withstand the explosion pressure without undergoing permanent deformation or rupture.

Pressure Overlap: When designing, engineers need to consider the pressure overlap effect that may occur in multi-chamber structures. In other words, the explosion of one chamber can trigger a more intense explosion in adjacent chambers through the connecting pipes. Therefore, the internal partitions or connection channels of your explosion-proof enclosure also need to have explosion-proof strength.

Flameproof Joints

The explosion-proof joint is the key to cooling the flame and achieving flame extinction.

The explosion-proof joint has various types. Among them, the flat joint is the most common. Two finely machined flat flanges are fastened together by bolts, with a predetermined gap in the middle.Besides, explosion-proof enclosures also have cylindrical joints, threaded joints, and labyrinth joints.

Clearance: The parameters of the joint need your precise control. The maximum allowable distance between the joints of the explosion-proof enclosure is usually between 0.1 and 0.5 millimeters. Generally, the smaller the gap, the stronger the flameout ability.

幅: The width is the minimum length of the metal contact surface that the flame must pass through. Generally speaking, the longer the width of your explosion-proof enclosure, the better the cooling effect.

Surface Roughness: The joint must be smooth and flat to guarantee a stable gap size. This is good for heat conduction. The Ra value for surface smoothness is typically required to be no more than 6.3 μm.

Fastening and Sealing

Special Fasteners: The number, strength, and depth of bolts for the explosion-proof enclosure are all strictly specified. Typically, the bolt heads of your explosion-proof enclosure need to guarantee that they will not loosen and fly off during an explosion.

Non-Elastic Sealing Gaskets: You should be aware that elastic sealing materials are not allowed for sealing the flame path joint. The explosion-proof joints usually use precise metal-to-metal machining for seal.

Static Sealing: For non-hazardous static sealing points on your enclosure, such as the nameplate and window of your explosion-proof enclosure, these parts can use aging-resistant elastic sealing components.

熱管理

The explosion-proof enclosure requires strict temperature control. Excessive heat can damage electrical components. If it is applied in hazardous environments, this will also increase the risk of explosion.

The explosion-proof enclosure in a hazardous environment must not exceed the temperature limit of its certified temperature group. For example, T4 ≤ 135℃, T6 ≤ 85℃. Explosion-proof enclosures usually use materials with high thermal resistance and do not affect the safety of the enclosure. The enclosures of high-power equipment are usually equipped with cooling systems and unique heat dissipation designs.

Compliance and Safety Margins

The explosion-proof enclosure needs to comply with international safety standards, such as IECEx, ATEX and NEC. Explosion-proof electrical enclosures with these certifications can guarantee safety and reliability when used in hazardous environments. You should check if the explosion-proof enclosure contains core information such as explosion-proof marks, certification agency logos, certificate numbers, etc.

How Electrical Enclosures Reduce Explosion Risks

Explosion-proof enclosures mainly help you reduce the risk of explosion through the following four interrelated levels in a systematic and progressive manner.

Space Isolation

The enclosure creates a physical barrier between the interior and the external environment. It guarantees that any internal sparks, arcs or hot surfaces are strictly confined within the cavity. Externally, it can prevent the rapid and large-scale invasion of dangerous gases. This greatly reduces the probability and concentration of the formation of internal explosive mixtures. Essentially, it helps you reduce the possibility of combustibles, oxidizers and ignition sources existing simultaneously in space.

Pressure Containment and Energy Conversion

The enclosure by using ultra high mechanical strength to absorb and dissipate mechanical energy of the explosion. The high mechanical strength enclosure can prevent the enclosure from cracking and generating metal fragments. This can directly help you eliminate the major risk of physical damage caused by electrical failures. What’s more, the shock wave energy of the explosion is converted into minute elastic deformation and sound energy of your enclosure. This also reduces the destructive kinetic energy of the explosion.

Eliminate the Flames

When an explosion occurs inside your explosion-proof enclosure, generating high-temperature flames and combustion products that are forced to pass through narrow and precise flange gaps, their heat is rapidly conducted to the metal enclosure. Therefore, the flame temperature is sharply reduced to below the autoignition point of the external flammable gas. This is the main method of cooling the flames.

Secondly, the combustion chain reaction requires highly active free radicals to keep. The walls of the metal enclosure can adsorb and combine these free radicals. Therefore, the combustion chain reaction is also interrupted.

The ultimate result is that the substance ejected from the joint changes from a high-temperature and highly active flame to a low-temperature and inert hot exhaust gas. This also means that the conditions for triggering chemical and thermal energy in the external environment have been completely eliminated. This helps you block the key path for the disaster to spread.

Standardized Design and System Compatibility

Safety Factor: The design pressure of the explosion-proof enclosure is much higher than the theoretically maximum explosion pressure. This design can deal with unforeseen anomalies.

Classification Management: The design of the product is usually strictly categorized according to gas groups(IIC, IIB, IIA) and temperature groups(T1-T6). This can provide more stringent protection in more dangerous environments for you. By matching risks, it helps you avoid insufficient or excessive protection.

Systematic Compatibility: All accessories of the explosion-proof enclosure must undergo the same level of certification to make sure that the entire barrier system is flawless.

Standards and Certifications

The explosion-proof enclosure is not determined by its appearance or material thickness. It needs to pass the verification of internationally recognized standards such as ATEX,IECEx, UL, which test its ability to safely contain an internal explosion without igniting the surrounding atmosphere.

ATEX (Europe)

ATEX is a legal threshold in the European Union, which is a mandatory product regulation. The directive ATEX 2014/34/EU mainly applies to equipment and protective systems. According to this directive, all explosion-proof equipment entering the EU market must be affixed with the CE and Ex marks. It contains directives regulating the responsibilities of manufacturers and employers respectively.

ATEX classifies hazardous environments based on the frequency of the occurrence of explosive gas atmospheres. The following is specifically addresses gases and vapors:

Zone 0: During normal operation, the explosive atmosphere persists continuously or for a long period of time.

Zone 1: Explosive gases may be present during normal operation.

Zone 2: The operating environment is unlikely to contain the explosive atmosphere or for a short duration.

For dusty operating environments, the directive also defines Zones 20, 21, and 22.

The instructions are classified into three categories based on the hazardous areas applicable to the equipment. Category 1 is suitable for Zone 0 or Zone 20 and provides very high protection to you. Category 2 is suitable for Zone 1 or Zone 21 and provides high protection to you. Category 3 is suitable for Zone 2 or Zone 22 and provides normal protection to you.

IECEx (International)

IECEx is an international certification system developed by the International Electrotechnical Commission. IECEx is accepted in regions outside Europe and is a globally recognized certification standard. If you choose products with IECEx certification, it can help you reduce the need for certifications in multiple countries. IECEx and ATEX are very similar in technology and share the same protection concepts, such as Ex d, Ex e, Ex i and Ex t, etc. Most products usually have dual certifications.

NEC/CEC (North America)

In North America (the United States and Canada), explosion-proof enclosures are typically based on a classification system. Currently, classification based on regions is also accepted.

NEC & CEC classified hazardous substances into three categories based on their types: Class I (gases and vapors),Class II (combustible dust), and Class III (fibers and flyings). Besides, it also divides it into Division 1 (hazard present under normal conditions) and Division 2 (hazard present under abnormal conditions) based on the frequency of occurrence conditions.

There are different groups for different gases, namely Group A (Acetylene), Group B (Hydrogen), Group C (Ethylene) and Group D (Propane). Dust is also classified into three grades: E, F and G.

UL/CSA

In North America, explosion-proof enclosures are usually certified by Underwriters Laboratories (UL – USA) and Canadian Standards Association (CSA – Canada). These certifications are based on tests that show the explosion-proof enclosures can withstand internal explosions, that the flame paths can cool the escaping gases and prevent them from igniting the external atmosphere. Certified explosion-proof enclosures must also meet mechanical and thermal requirements.

Ingress Protection vs Explosion Protection

You should note that IP 定格 mainly protect against dust and water, and NEMA ratings focus on environmental protection. Although both of them have some overlap with the protection of hazardous areas, they are not equivalent to ATEX or IECEx. Therefore, an enclosure that can resist dust and water is not explosion-proof.

Applications of Explosion-Proof and Flameproof Electrical Enclosures

石油・ガス産業

The oil and gas industry is the field with the most stringent explosion-proof requirements and the widest application. Its applications cover the entire process of extraction, transportation and refining. In these environments, such as offshore rigs, refineries and processing plants, flammable and explosive gases persist or frequently occur.

These environments are mostly Zone 1. The environment contains a large number of application devices that may become ignition sources. Explosion-proof enclosures can make sure that internal faults or explosions will not become ignition sources.

Chemical Processing Plants&Pharmaceutical Manufacturing

These two industries have similar production environments. The pharmaceutical industry has additional hygiene requirements. Both environments contain complex solvent vapors and flammable dusts. The risk of dust is more prominent in the drug production process. Hidden ignition sources are mostly found in automated control systems such as mixers and drying equipment.

In this environment, your explosion-proof enclosure needs to meet both gas explosion-proof (Ex d, Ex e) and dust explosion-proof (Ex tD) requirements simultaneously. You can also choose a composite protection enclosure. Besides, your explosion-proof enclosure needs to withstand frequent and high-intensity chemical cleaning agent rinsing and corrosion.

Mining

In an environment filled with methane gas and coal dust, all electrical equipment must use enclosures of the highest protection level. For electrical enclosures, you usually need to choose explosion-proof and intrinsically safe types.

Besides explosion protection, the enclosures also need to have extremely high mechanical strength (IK Rating). This can effectively prevent damage caused by rock impacts. You need to choose enclosures with heavy-duty flanges and reinforced rib designs.

Renewable Energy

Common application scenarios in the renewable energy industry include biogas power generation, hydrogen energy and wind power generation. These power generation facilities are usually located in remote areas, so you need to choose enclosures that are environmentally resistant, and also need to protect the equipment from salt fog and ultraviolet rays.

If you apply it to hydrogen facilities, you must use explosion-proof enclosures with the IIC gas group designation. This is the current highest level of gas explosion protection standard.

Industrial Manufacturing

The industrial manufacturing environment is a broad field, but you cannot underestimate its risks. The major risks in this environment come from flammable dust, such as metal dust, wood dust, plastic dust, etc.

In areas where dust may be ignited, dust explosion-proof enclosures (Ex tD) need to limit the surface temperature and prevent dust from entering the interior. An initial explosion in a workshop may kick up accumulated dust and cause a secondary explosion. The explosion-proof enclosures can effectively contain the initial explosion.

Limitations and Common Misconceptions

- The enclosure is thick and well-sealed, so it has explosion-proof capabilities.

The only way to tell if an enclosure is explosion-proof is to check for an explosion protection certification mark, such as Ex, IECEx, etc. An enclosure without these marks is just a standard electrical enclosure, no matter how strong it is.

- The rusting and peeling on the enclosure do not affect the function of the explosion-proof.

Corrosion on the precision explosion-proof joint will change the width of the gap and the surface finish. This will cause some of its functions to fail. Therefore, you need to assess and deal with any rust.

- The explosion-proof electrical enclosure can be used in any hazardous environment.

Explosion-proof certification has specific applicable conditions. These include gas categories (IIC, IIB, IIA), temperature categories (T1-T6), and environmental temperature range (Ta). If you use an enclosure for IIB in an IIC environment, it is very dangerous.

よくある質問

Can An Explosion Proof Enclosure Stop An Explosion Completely?

Explosion-proof enclosures cannot completely stop internal explosions. Its function is to contain the explosion and cool the escaping gases. This can prevent the ignition of the surrounding gas.

Can Improper Installation Reduce Explosion Protection?

Yes. Wrong Installation and poor maintenance will substantially reduce or eliminate explosion protection.

How Do You Choose the Right Electrical Enclosure for Explosion Protection?

You should evaluate the environment, hazard classification, system requirements and more conditions. And then choose a certified enclosure designed for your conditions.

Final Thought

KDM is a professional manufacturer of custom electrical enclosures. No matter what industry and application environment you need electrical housing, we can meet your custom needs. We have collaborated with many internationally renowned brands and had many certifications. We have a professional team dedicated to your customized production plan. If you have any requirements for customizing electrical enclosures, please feel free to お問い合わせ.