An important part of the power system is power distribution. Busbars and terminal blocks are the key components for controlling the flow of current. Although they have similar electrical connection functions, their designs and applications are significantly different. This article analyzes their differences from current processing capacity, modularization and flexibility,etc. If you don’t know how to choose between the two, this article can help you find the power distribution plan that suits you.

What is Terminal Block

Definition of Terminal Block

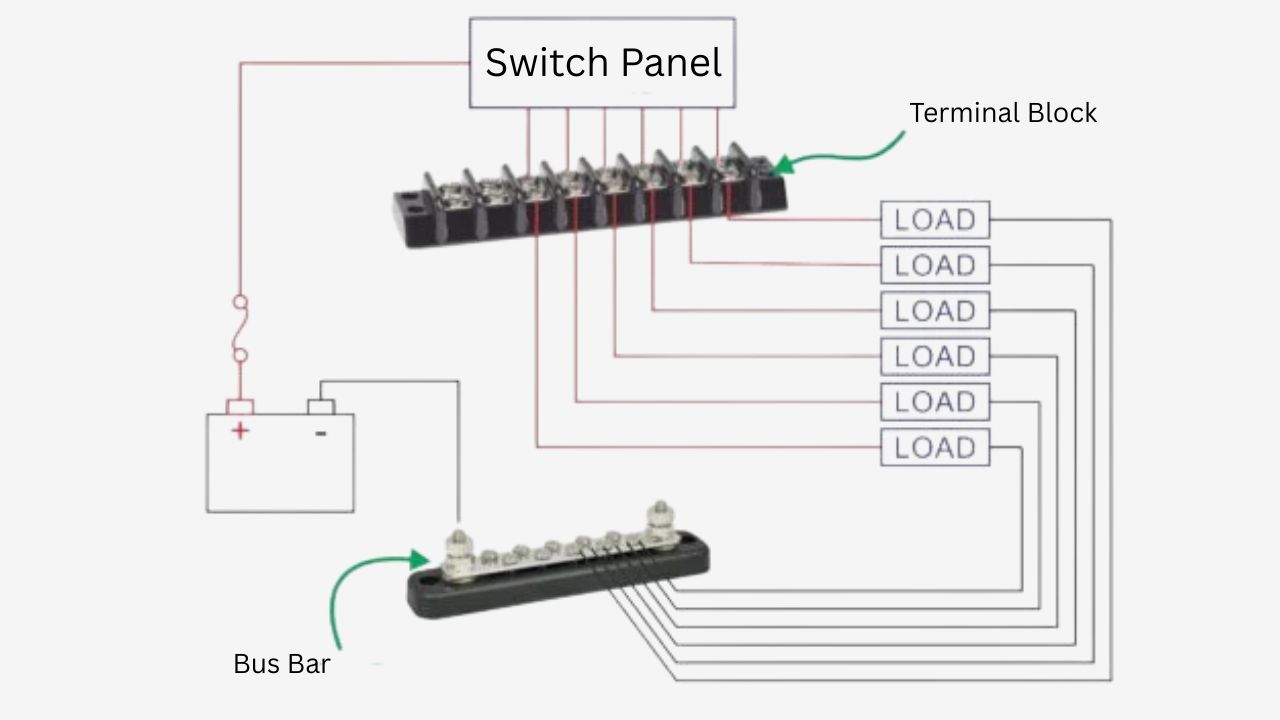

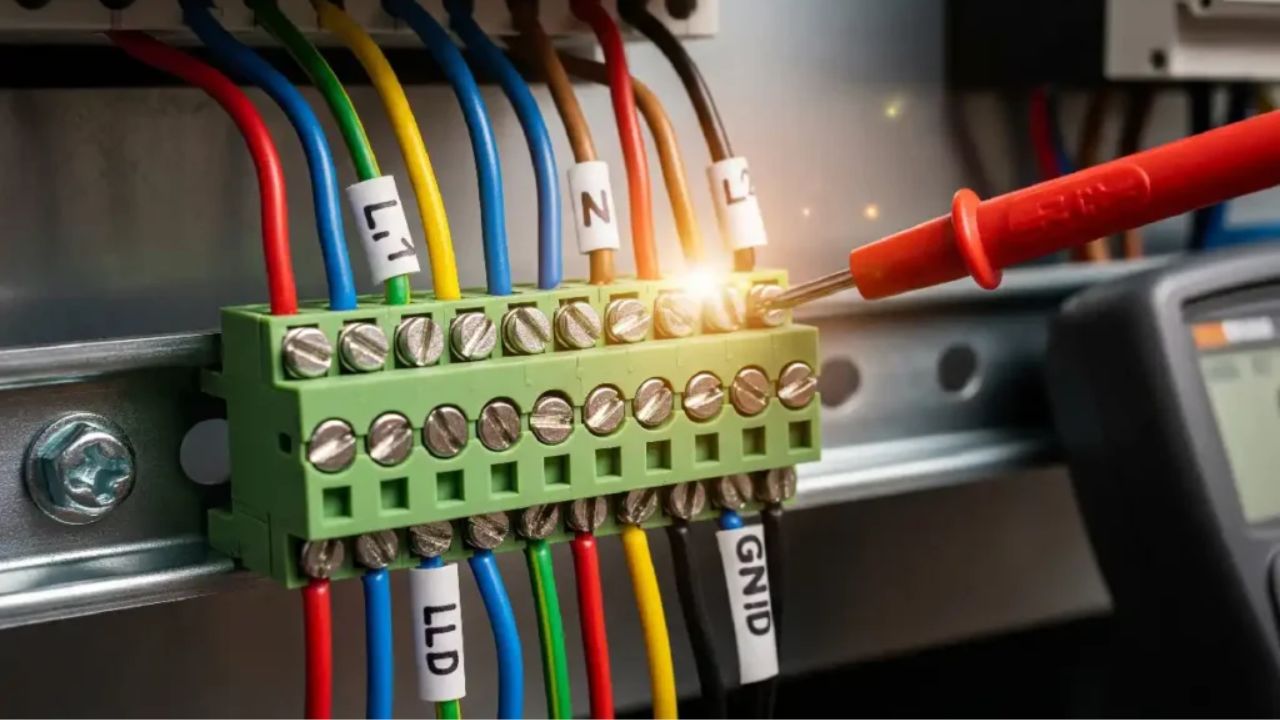

Terminal blocks, also known as terminal connectors, are modular insulated electronic connectors that can achieve safe, orderly and reliable electrical connections. Its core function is to serve as a wiring hub or transfer station for the electrical system.

It is usually composed of a base made of insulating material and multiple independent metal conductors arranged on it. Each conductor unit is equipped with a clamping mechanism, like a screw, spring or push-in.

Its function is not limited to organizing or fixing multiple wires together. It can also distribute a power supply or signal to multiple branches, and conversely, converge signals.

Types of Terminal Block

There are various types of terminal blocks. The following are the widely used types of terminal blocks:

Spring-clamp Terminal Block: Use the elastic force of the spring to clamp the wire. It can be installed quickly, has excellent anti-vibration performance and can provide a long-lasting and reliable connection.

Pluggable Terminal Block: It consists of a base and a plug. It has excellent maintainability, allowing quick connection and disconnection of wires, which is convenient for equipment assembly and replacement.

Fused Terminal Block: Integrated fuse holder, the fuse provides overcurrent protection for the circuit.

Grounding Terminal Block: It is used for a safe connection ground wire, providing a safe return path for fault currents to prevent electric shock and fire.

What is Bus Bar

Definition of Bus Bar

あ Bus bar is one or more strip-shaped conductors made of highly conductive metals. It is usually made of conductive materials such as copper または アルミニウム and is often wrapped in an insulating shell or fixed by insulating support pieces.

It can collect large currents and distribute them to branch circuits, reducing loop resistance and minimizing voltage loss and energy expenditure. It can also enhance space utilization and heat dissipation efficiency, improve system reliability and consistency, and is a dedicated conductor in electrical systems for efficiently and centrally collecting and distributing electrical energy.

Types of Bus bar Arrangements in Electrical Systems

Single Busbar Arrangement: All equipment is connected by a single busbar, and a fault will affect the entire circuit.

Ring Main Wiring Arrangement: A system that is not easy to expand and provides another operation system for faulty circuits.

Main and Transfer Bus Arrangement: Guarantee power redirection during faults, allow for maintenance, and enhance system reliability, flexibility and efficiency.

Double Busbar Double Breaker Wiring: Two buses and two circuit breakers per feeder or load make the system more resilient to failures and more flexible to operate.

Comparison Between Terminal Block and Bus Bar

Connection Type

端子台: Point-to-point, discrete connection. You need to operate the clamping mechanism with a screwdriver or wire crimping pliers, which will apply a strong mechanical clamping force to the wire.

The clamping force forms a low-resistance physical connection point, allowing current to flow in from one wire and then through the metal conductor to the other connecting wire. Each metal conductor is independent and can establish reliable electrical isolation, free from interference by other paths.

バスバー: Main trunk type, parallel connection. You need to connect the power cables of all equipotential devices directly to different contact points on the same conductor bus bar through branch connectors. It provides a continuous, low-resistance common conductor path. The core principle lies in minimizing the resistance of the current flow path and distributing power to multiple load points with minimal loss.

Current Handling Capability

端子台: The terminal block can only withstand low to medium currents, and its current handling capacity is relatively weak.The main reasons that limit its current processing capacity lie in the cross-sectional area of the metal conductor within a single terminal and the heat dissipation capacity of the clamping mechanism.

The terminal block performs well in small-scale applications. But for high-current applications, the use of high-current terminals can cause complex cables and may not be the best choice for you.

バスバー: It is designed for medium to large currents. Their low impedance characteristics result in significantly lower temperature rise and voltage drop compared to solutions using multiple separate cables and terminals.

Electrical Isolation

端子台: Each terminal itself is a complete insulator. The channels are isolated from each other and insulated externally. The insulating base can ensure that there is sufficient electrical clearance and creepage distance between adjacent terminals and between you and the live body. This is its inherent safety feature.

バスバー: Bare busbars rely on air gaps and insulating supports for insulation, which poses a relatively high risk. Modern industry typically employs fully enclosed insulating enclosures to completely wrap conductors and provide touch protection.

スペース要件

端子台: It usually expands vertically. When you need more connection points, it is usually necessary to increase the number of terminals horizontally on the rail. This usually requires a larger area and more space for line management.

You can install it in areas where there are many signal lines but the line diameters are not large, which makes it easier to lay out the lines neatly. However, in the high-current distribution area, the terminal block connector will appear bloated and inefficient.

バスバー: It is usually used for horizontal integration. You can use busbar to integrate the originally numerous parallel in-store paths into flat, compact rigid conductors, greatly saving cable channel space.

Busbar can compress the power distribution system to the extreme, optimize the air duct and enhance the overall reliability, especially in situations where servo drives and frequency converters are densely distributed.

Flexibility and Modularity

端子台: Terminal connectors can be added, reduced or replaced at any time. You can also easily change the wiring relationship. It is highly suitable for debugging, testing and later modification, and is very flexible.

バスバー:Traditional custom busbars are almost impossible to change after installation. Modern modular insulated busbar systems need to provide standard lengths and prefabricated outlet holes, allowing for the selection of connection points within a certain range. Its flexibility needs to be improved and it requires prior planning.

Cost Consideration

端子台: It is more suitable for small-scale installation because of its low initial cost. When used for high current and multi-point power distribution, it requires more installation time and has higher long-term operating energy consumption.

バスバー: The initial procurement and design costs of bus bars are relatively high, but the long-term total cost is lower. In the long run, it can save you cables, time and also reduce energy consumption. If you use it when the project has large scale or the current is high, you can recover the initial investment quickly.

Different Applications

端子台: Terminal blocks are usually used in control panels, smaller electrical systems, automation systems and industrial machinery. It is also applicable to signal connections and low-power distribution. It offers convenient access and servicing, making it more suitable for occasions that require frequent testing, maintenance and adjustment.

バスバー: Busbars are more suitable for high-current applications and feature higher efficiency and reliability. It is widely used in switchgear, power distribution in industrial settings,battery banks, substations and large-scale power systems.

How to Choose the Right Option

Facing different application scenarios, how do you find the appropriate power distribution scheme between terminal connectors and busbar? Different choices will have a important impact on the efficiency and maintenance of the power system. A reasonable power distribution plan is crucial for system performance. And it is also related to life safety and electrical safety. The following are suggestions for you to make the right choice.

The first step in making a choice is to prioritize analyzing the core demands of the power system.

For example, if you need to safely, orderly and isolate wires from different sources and with different functions together, terminal blocks are undoubtedly the ideal choice.

If you need to distribute the electrical energy from a single power source to multiple parallel loads with minimum loss and maximum efficiency, you can choose a busbar.

For more specific applications, such as signal circuits with diverse voltages, low currents, and a large number of loops, terminal blocks are the preferred choice. They provide high isolation and clear labels for easy testing.

On the other hand, for highly sensitive power supply circuits like those in servo drives, bus bars should be selected. They can neutralize magnetic fields and reduce loop inductance, thereby preventing device damage or interference.

In complex industrial cabinets, terminal rows and bus bars can be used to assist in building an efficient, reliable, and easy to keep system.

Besides, you also need to think about problems such as voltage and current ratings, wire materials and sizes, application environments, and costs. If you still have doubts, you can also consult experienced electrical accessory suppliers.

よくある質問

Can Bus Bars Completely Replace All Terminal Blocks in a Control Cabinet?

No. Busbars cannot completely replace all terminal blocks in the control cabinet. The core functions of the two are not the same. Busbars are mainly used for the efficient and centralized distribution of the same power supply. Terminal blocks are mainly used to safely and isolated connect and distribute wires from different sources. Busbars cannot replace terminal bars in terms of signal isolation, interface conversion and other functions.

Is PE Bar a Terminal Block or a Bus Bar?

A PE bar is essentially a bus bar specifically designed for grounding. While its appearance resembles a terminal block, its core function matches with a bus bar. Therefore, in electrical equipment classification, it is commonly referred to as a grounding busbar.

How can Bus Bars and Terminal Blocks be Used Together?

In complex electrical systems, the bus bar primarily serves as the main power path, connecting to terminal blocks through its interfaces. The terminal block is responsible for safely and orderly distributing power to various end devices.This cooperative way balances the efficiency of high current transmission with the flexibility and security of branch circuit distribution.

Why do Bus Bars Enclosed in Insulation Have Better Heat Dissipation than Terminal Blocks?

The core conductor of the busbar has a large area of continuous metal cross-section and surface area. It can conduct heat efficiently and dissipate heat evenly through metal. In contrast, terminal blocks rely mainly on contact points for heat dissipation, resulting in a smaller overall heat dissipation area and lower efficiency.

Final Thought

KDM is committed to providing you with high-quality power distribution components. As a veteran manufacturer in the industry, we strictly control raw materials and conduct multiple quality inspections to produce high-quality electrical enclosures. Whether it’s busbar or terminal block, we can provide you with high-quality and efficient customized electrical enclosure solutions to solve your power distribution problems.Please feel free お問い合わせ. We will respond promptly to meet your customized needs.