As the cornerstone of the power network, the three-phase transformer has various uses such as boost transmission, buck distribution, and electrical isolation. The size of a three-phase transformer is crucial for both initial investment and operational performance. How to choose the transformer size that matches your voltage requirements?This article discusses the importance and influence factors of transformer size to help you choose the suitable transformer size to balance safety, efficiency and cost.

What are Three Phase Transformers?

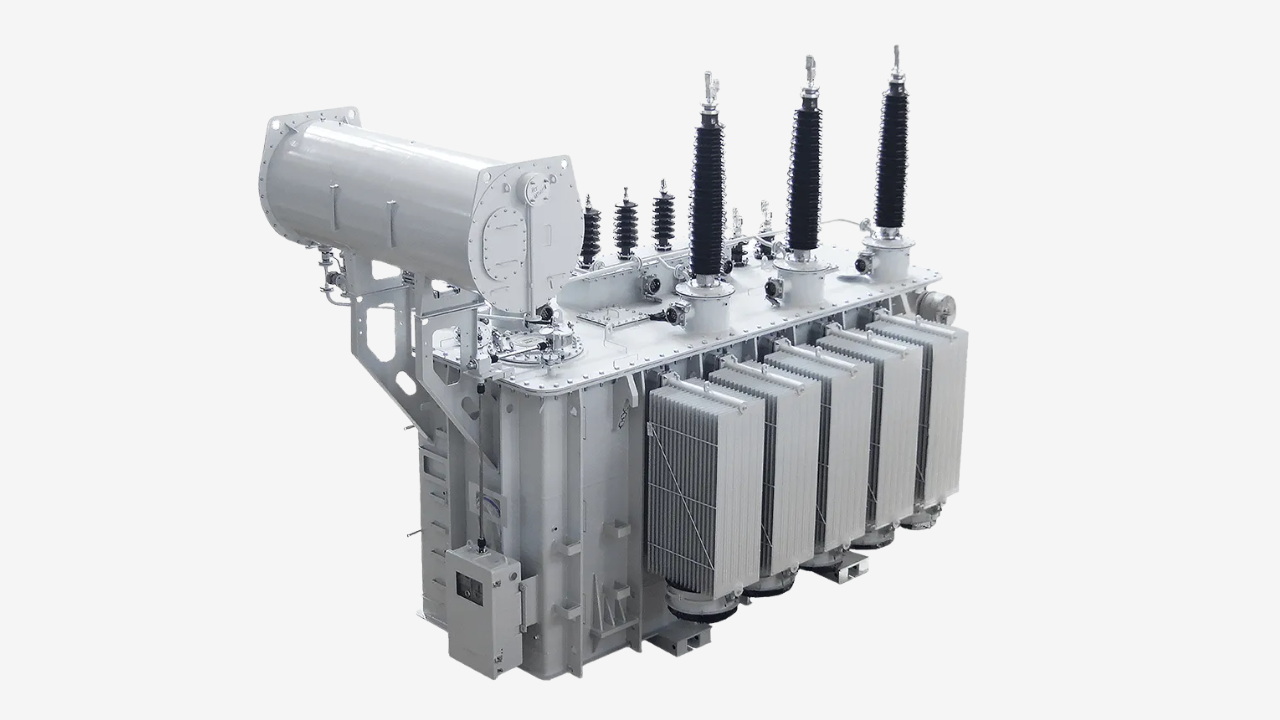

The three phase transformer is a static electrical device that uses the principle of electromagnetic induction to transmit and distribute three-phase alternating current power at the same frequency, but usually at different voltage levels.

The three phase transformer mainly consisted of several major systems: the magnetic circuit system, the electrical circuit system, the insulation and cooling system, the protection and monitoring system, and the structural components and casing. They can respectively provide efficient magnetic paths, achieve electrical energy input, output and voltage conversion, verify electrical insulation and heat dissipation, guarantee the safe operation and status control of محولات, and realize mechanical support, protection and electrical connection.

Through the precise coordination among systems, Three-phase transformers achieve efficient, reliable and flexible power conversion and transmission, forming the cornerstone of modern power networks.It can efficiently transform three voltages from a three-phase power supply to another three-phase system through a common core magnetic circuit.It has become an indispensable important equipment in modern power systems from generation, transmission to distribution.

Three Phase Transformer Sizes

Generally, small, three phase transformer sizes are mainly classified according to their rated capacity (KVA). However, this classification is not absolute. There will also be changes in classification based on your usage and cooling methods. The following is an explanation of the three types of three-phase transformers based on common understanding and typical application scenarios.

Small Three Phase Transformers

Typical Rating: The rated capacity of small-sized three-phase transformers is usually between 10kVA and 500kVA. Typical transformer kVA sizes include 15kVA, 30kVA, 50kVA, 100kVA, 250kVA, and 500KVA.

سمات: Small three-phase transformer design pursuit of miniaturization, compact structure, suitable for installation in the platform or indoor distribution room. The design of standard three-phase transformer sizes can also control manufacturing costs. The cooling methods are mostly ONAN(oil filled), AN or AF (dry type).

Common Uses: Three-phase transformers of these sizes are typically used to provide independent and safe power supply for small industrial equipment, commercial centers, and specific areas of buildings.

Medium Three Phase Transformers

Typical Rating: The rated capacity of medium-sized three-phase transformers is usually within the range of 500kVA to 10MVA (10,000kVA). The typical transformer kVA sizes are only 750kVA, 1MVA, 2.5MVA, 5MVA, 7.5MVA, and 10MVA.

سمات: Medium-sized three-phase transformers can strike the best balance between cost, efficiency and reliability, and therefore are also the most technologically mature and widely used category.

According to the load rate and environmental conditions, medium-sized three-phase transformers usually adopt oil-filled cooling methods, like ONAN(Oil Natural Air Natural) and ONAF(Oil Natural Air Forced). For dry-type three-phase transformers, AF is often adopted. The size of this type of transformer can also meet high customization requirements.

Common Uses: Medium-sized transformers can be used in regional distribution and transmission hubs, or installed in the distribution rooms of large commercial facilities or the main distribution substations of industrial plants.

Large Three Phase Transformers

Typical Rating: Large three-phase transformers are usually over 10MVA, and the maximum can even reach over 1000MVA. Typical transformer kVA sizes include 20MVA, 50MVA,100MVA and 250MVA.

سمات: The production technology of large three-phase transformers is more complex, and almost all of them need to be custom-made.

Among them, insulation design is a production difficulty, and the transformer must adopt a forced cooling method to counteract the heat generated by high-power transmission.

Ultra-high power transmission and powerful cooling inevitably face huge physical dimensions and weights, and also require extremely high efficiency.

Common Uses: The large three-phase transformer can be used as the main transformer of thermal power, hydropower and nuclear power plants. It can also be used as the main transformer for ultra-high or extra-high voltage substations or as a collection and step-up substation in large-scale renewable energy bases.

How to Size a Three Phase Transformer?

Sizing a three-phase transformer means selecting a kVA/MVA rating and voltage rating that can safely supply your load.

Determine the Load Power

Determining the load power is the most fundamental and crucial step. At this step, you need to calculate the total apparent power (kVA) required by all load devices, rather than the active power (kW).

First, you need to list all the loads that the transformer will supply. The key parameters of these loads include rated power (kW) and power factor (PF). Then you also need to convert the power of each load into kVA. For three-phase loads, you can use the formula, load (kVA) = Active power of the load (kW)/power factor (PF).

It should be noted that you know not all devices are operating at full capacity simultaneously. Therefore, you need to select a demand factor less than 1 based on industry standards or actual operational experience and multiply it by the total connected load.Finally, the kVA values for all the loads are added together to get the minimum kVA required for the current run.

Add Future Growth and Margin

As a long-term asset, transformers cannot operate at 100% full load for a long time, which will shorten service life and increase losses. Therefore, you need to reserve a certain margin for safe operation, usually 10% to 15%.

You also need to consider the long-term development of three-phase transformers. Based on your enterprise or project planning, estimate the possible increase in load in the coming years. Generally speaking, increasing the margin in the future is likely to increase by about 20% to 30%.

Therefore, you can calculate your total capacity requirement, kVA = current operating demand *(1+ future growth %+ safety margin %)

Select Primary and Secondary Voltages

At this stage, you need to choose the voltage according to the supply and load. The input high voltage on the primary side is usually determined by the power supply grid.Common North American voltage has 12.47kV, 4.16kV, etc., China has 10kV, 35kV, 110kV, etc.

The secondary voltage, that is, the low output voltage, is usually determined by the electrical equipment within the factory or building. The common standards in Europe and China are 400V/230V, while those in North America are 480V/277V and 208V/120V. Besides, you also need to confirm whether the transformer is equipped with a tap changer, which can better adapt to the fluctuations of grid voltage.

Calculate Full Load Current

Calculating the full-load current can better protect switches, cables and calibration equipment. The formula is usually used: full-load current (Amps) =kVA*1000/(Voltages(Volts)*√3).

It should be noted that √3 usually takes the value of 1.732. And you need to calculate the currents on the primary side and the secondary side respectively, and use the calculated results to select the corresponding devices on the side.

Choose Transformer Connection

You need to choose the appropriate winding configuration because it will affect the voltage availability and harmonic mitigation. The following are common winding configurations.

| Connection | Primary/High Side | Secondary/Low Side | Key Characteristics&Application |

| Delta-Wye(Δ-Y) | Delta | Wye | Most commonly used. The secondary side can provide a stable neutral point for single-phase loads and three-phase motors.This connection helps to suppress the third harmonic and is suitable for modern distribution systems. |

| Delta-Delta(Δ-Δ) | Delta | Delta | It is used for pure three-phase industrial loads, such as large motors and rectifier equipment. There is no third harmonic circulating current problem, but no neutral point. |

| Wye-Wye(Y-Y) | Wye | Wye | Often used in old industrial systems. Sensitive to three-phase unbalanced loads and the neutral point shifts. It is suitable for occasions where three-phase power loads are dominant and single-phase loads are small and balanced. |

| Wye-Delta(Y-Δ) | Wye | Delta | Step-down transformers commonly used in substations reduce high voltage to medium voltage. There is no neutral point on the secondary side. |

ملحوظة: For the majority of industrial and commercial building power distribution, the Delta-Wye (Δ-Y) connection group is the preferred configuration.

Select Standard Transformer Rating

Transformers need to be produced in accordance with the standard capacity series, and the capacity cannot be customized arbitrarily. Generally speaking, you can look for the standard three phase transformer size that is closest to your capacity requirements.

According to the IEC standard series (kVA): 75 kVA, 100 kVA, 125 kVA, 160 kVA, 200 kVA, 250 kVA, 315 kVA, 400 kVA, 500 kVA, 630 kVA, 800 kVA, 1000 kVA, etc. For instance, if your capacity requirement is 145.6kVA, you need to find a larger and closer standard transformer size. Therefore, ultimately you can select a 160kVA transformer that complies with IEC standards.

Finally, you also need to recalculate the rated full-load current of the transformer based on its finally selected rated capacity to protect the electrical appliances.

Based on this method, you can deduce the technically reasonable and economically optimal size of the three-phase transformer. Moreover, you also need to abide by the national and local electrical design standards. It is recommended that you conduct the final review and confirmation with a professional electrical engineer.

What Factors Affect the Size of a Three-phase Transformer?

Total Load

This is the most direct factor determining the size of the transformer. The cross-sectional areas of the core and the windings will increase as the load increases. For almost every doubling of capacity (kVA), the size and weight of the transformer will increase to about twice the original size.

Power Factor

A low power factor means that the system needs to transmit more current (kVA) for the same amount of active power (kW). A low power factor requires a larger-capacity transformer and larger cross-sectional area of the winding. This also affects the size of the transformer.

Load Type

The rated capacity of a transformer can be directly determined based on the kVA demand of a linear load. However, for the harmonic currents generated by non-linear loads, transformers usually require special designs.

For instance, using a reduced capacity would increase the size, using a reduced-loss winding structure or even dedicated harmonic shielding groups would increase the physical size and manufacturing cost.

Voltage and Current Level

The higher the voltage on the primary side, the greater the insulation distance requirement. This results in thicker insulation layers, larger winding dimensions, and increased creepage distance, etc. The larger the current on the secondary side, the larger the cross-sectional area of the required conductor.

التوسع المستقبلي

The future expansion margin will increase the size of the core, windings and the cooling system. This will also cause the transformer to operate under light load, reducing its operational efficiency and economic performance.

Design and Material

Different core materials will have a great impact on the cross-sectional area and weight of the core. Silicon steel sheets will reduce the cross-sectional area and weight of the core at the same capacity.

Different winding materials will also affect the size and manufacturing cost of the winding. Generally, copper has a higher conductivity and the winding is smaller.

Higher heat resistance levels allow transformers to handle larger load currents and have a compact design.

How to Choose an Appropriated Three Phase Transformer Sizes?

A suitable three-phase transformer determines the reliability, economy and long-term operational efficiency of the power system. This is a systematic project for you.

Accurate Calculation of Electrical Capacity

You still need to list all the load equipment that the three-phase transformer needs to supply. And you also need to record key parameters such as the rated power and power factor of each device.

You should find the appropriate required coefficient by referring to national standards or consulting experienced engineers or industry experts. And calculate the ratio of the maximum comprehensive load of the entire system to the sum of the maximum demands of each subsystem based on the simultaneous coefficient.

Finally, the active power is calculated based on the formula active power (kW) =Σ(installed power of equipment * required coefficient) *simultaneous coefficient.Then, calculate the required capacity, kVA=kW/ average power factor.

As above mentioned, merely calculating the size you need is not enough. For the safety and long-term operation of the equipment, you also need to consider the future margin and the optimal load rate of the transformer.

Avoid simply adding up the power of the devices. Incorrect transformer size selection will influence your investment cost, no-load loss and economic performance.

Selection of Appropriate Technical Type of Three-phase Transformer

Three-phase transformers can generally be classified into two types: oil-filled and dry-type. Dry-type three-phase transformers have higher fire safety and require no maintenance. Oil-immersed three-phase transformers have stronger overload capacity and lower noise.

For example, they are applied in high-rise buildings, underground facilities, densely populated areas, or places with fire prevention and explosion prevention requirements. For safety considerations, dry-type transformers must be selected in such cases. Outdoor substations and cost-sensitive industrial projects can consider using oil-filled transformers.

Overall, this is mainly determined by your installation environment, security standards, and maintenance requirements.

Selection of Suitable Cooling Method

If you want to optimize the size and operational characteristics of a three-phase transformer, the choice of cooling method is also particularly important.

According to the IEC standards, the cooling methods for oil-filled transformers are classified as ONAN, ONAF, and OFAF.

ONAN: It is simple, noise-free and requires no maintenance. However, its heat dissipation efficiency is low and it is suitable for small and medium-sized transformers.

ONAF: It has a higher heat dissipation capacity and a more compact transformer design. It is the mainstream choice for balancing size, capacity and cost, and is more suitable for medium to large transformer sizes.

OFAF: It has the highest heat dissipation efficiency, but its structure is complex and maintenance requirements are high. It is more suitable for large and extra-large transformer.

The cooling methods for dry-type transformers are classified as AN and AF.

AN: Operates silently but has limited cooling capacity. Suitable for indoor scenarios with medium-sized rating and low load rates.

AF: Allows for a smaller physical size while achieving a larger transformer kVA size. It is the preferred choice for saving indoor space.

Ensuring Adequate Transportation Routes and Installation Space

Apart from choosing the electrical specifications, you also need to conduct a thorough investigation of the transportation route and customize a dedicated transportation plan.

Based on the size of the transformer, you need to make a reasonable plan for the installation space. According to IEC or ISO standards, reserve sufficient space for maintenance passages, ventilation distances, and electrical safety distances.

Guarantee that the building structure can bear the weight of the transformer. You also need to determine the cable entry and exit methods and reserve the corresponding space.

Comprehensive Evaluation and Analysis

Finally, you need to do a total cost of ownership analysis based on you, including the initial head, running costs, maintenance costs, etc. Besides, you also need to implement a reliability assessment of the manufacturer’s qualifications and the quality of the transformer core components.

If there are strict environmental regulations in your area, you also need to confirm whether the product meets the local mandatory energy efficiency standards and environmental requirements.

التعليمات

Why Is the Size of a Three Phase Transformer So Important?

The physical size of the transformer determines the smooth installation. Transformer size (kVA) is associated with procurement costs and operational safety. The correct size can guarantee that the transformer operates efficiently and reliably at the optimal load rate. It determines the selection of upstream and downstream cables, switches and protective equipment, and is also the foundation for the stable operation of the entire power supply system.

Is A Larger Transformer Size Necessarily Safer?

Not necessarily. Excessive size will increase the short-circuit current, which will raise the requirements for قواطع الدائرة and protection equipment. If the equipment does not match, it may not be able to cut off the current in time during a fault, leading to a more serious accident. Safety does not lie in physical size, but in the matching of capacity and the completeness of protection.

Why Are Amorphous Alloy Transformers Large and Expensive?

The large size is due to its relatively low magnetic saturation density. Therefore, to achieve the same magnetic flux, the cross-sectional area of the iron core needs to be made larger, which consequently leads to an increase in its volume and weight. The high price lies in its high material cost, difficult processing and energy-saving premium. It is more suitable for scenarios that operate uninterrupted all year round and focus on long-term power saving.

Final Thought

KDM is a custom manufacturer dedicated to providing you with high-quality electrical enclosures. All of our products are made from premium materials and using advanced processing techniques. We also hold multiple certifications to guarantee the safety and reliability of your enclosures. If you have any customization requirements, please feel free to اتصل بنا. We will respond promptly and provide you with a satisfactory customized solution.