Stainless steel pressure vessels are simply storage tank which are used in multiple industries to hold gases and liquids at different pressure levels. You can consider these vessels safe to carry high-pressure chemicals, which are efficient in their operations. Being an industrial buyer, the appropriate choice of the vessel is critical in terms of safety and cost-efficiency. This article will guide you on the types, benefits, and uses to make the correct decision on which to use in your business.

Understanding of Stainless Steel Pressure Vessel

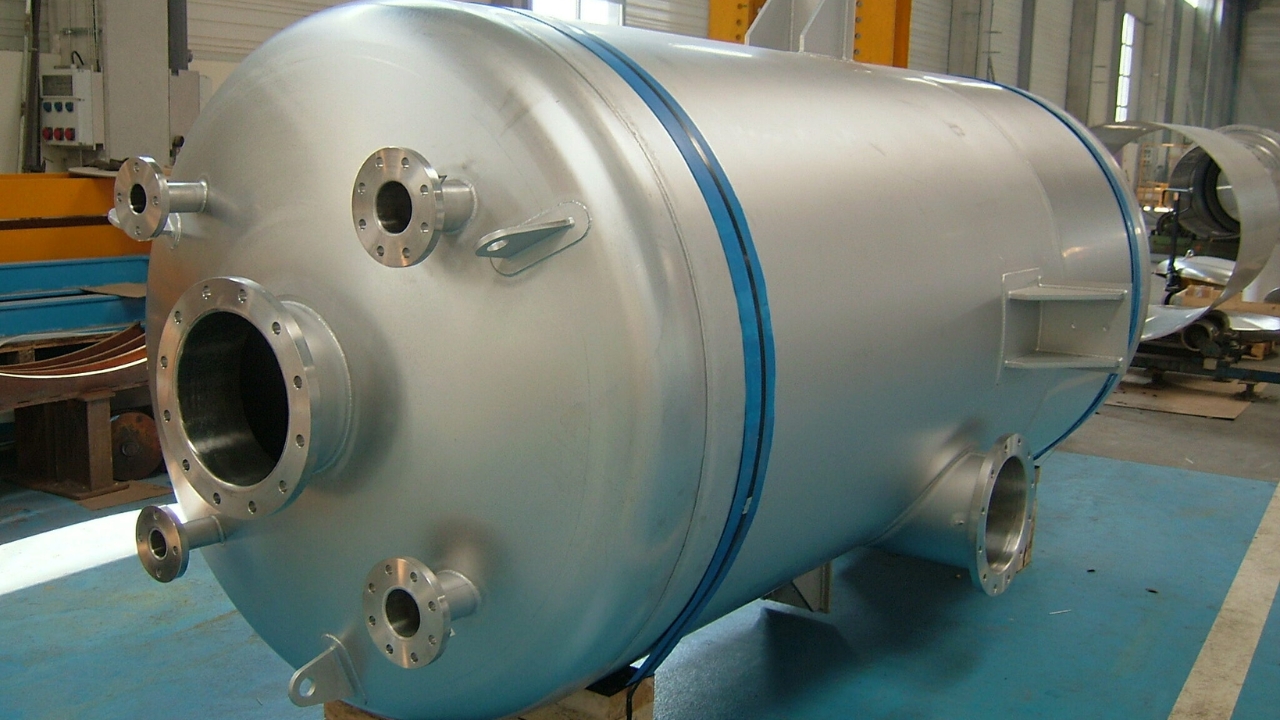

A stainless steel pressure vessel is a vessel that is used to contain gases or liquids under high pressure. It is constructed of stainless steel, which is resistant to corrosion. Such vessels are applied in industries such as chemicals, pharmaceuticals, and oil and gas. They guarantee safe storage, transportation, and handling of pressurized substances at controlled conditions.

Types of Stainless Steel Pressure Vessels

Based on Design and Structure

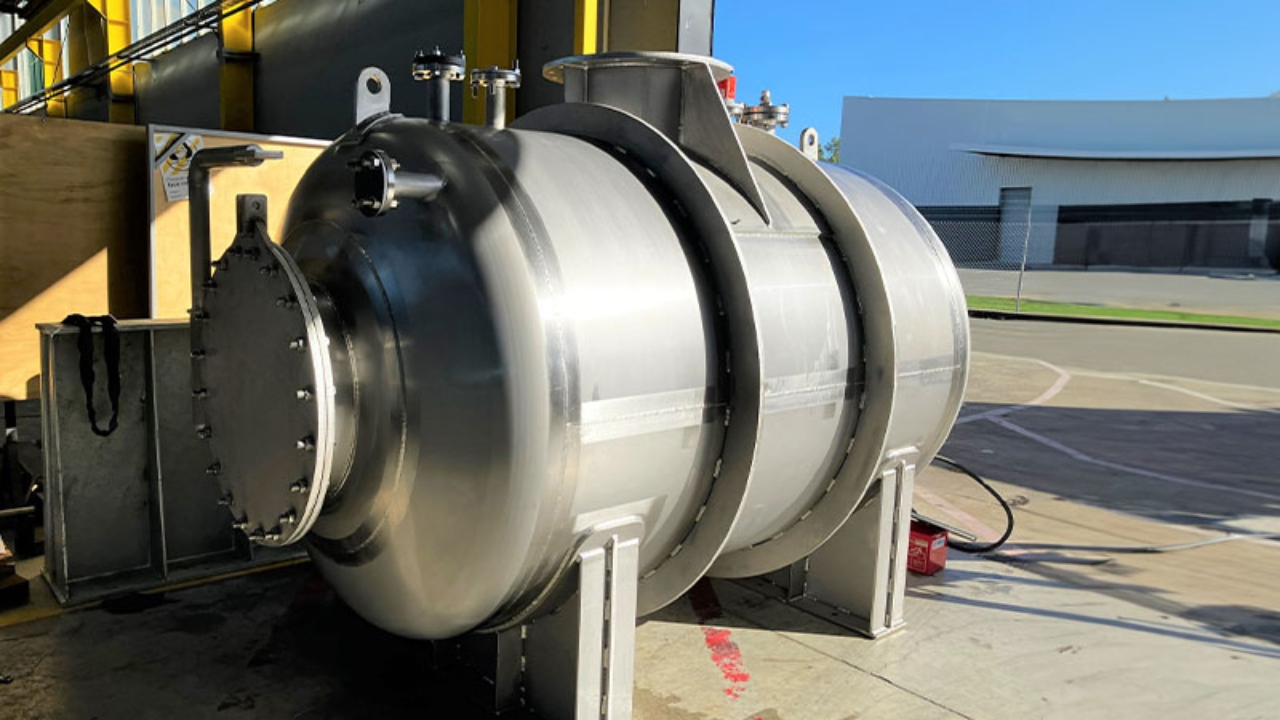

- Horizontal Vessels

These are the vessels that lie horizontally to ensure that floor space is maximized. They are usually employed in industries where there is a lack of space, like in oil and gas or chemical process industries.

- Vertical Vessels

Vertical vessels are erect and conserve the floor space. They are suitable for the use of processes that need gravity separation and a small installation in the process industries.

- Cylindrical and Spherical Vessels

Cylindrical vessels are commonly used in storage, whereas spherical vessels are used to deal with increased pressure. Both designs are good and useful in a pressurized environment.

Based on Function / Special Design Types

- Storage Pressure Vessels

The storage pressure vessels are used to store liquids or gases under high pressure. They are also in use in other industries such as energy and chemicals, where they are being used to store their goods efficiently.

- Process Pressure Vessels

The vessels are applied in the chemical processes and reactions, which are characterized by high pressure. They play a key role in the regulation of process variables within such industries as pharmaceuticals and chemicals.

- Vacuum Vessels

Vacuum vessels are utilized in order to establish a vacuum environment. They find use in industries and laboratories where pressure is crucial in chemical reactions or material handling.

- Jacketed Pressure Vessels

These pressure vessels are used to contain or adjust the temperature of the products. They are applied in the processes that demand thermal control, like food and pharmaceutical processing.

Based on Industry Standards

- ASME Certified Vessels

ال certification of ASME (American Society of Mechanical Engineers) is used to certify pressure vessels to high safety and quality standards. These vessels are carefully designed, constructed, and tested to ensure high-pressure usability and safety.

- Custom Pressure Vessels

There are custom pressure vessels which are designed to suit particular operational needs. These vessels are made and constructed to accommodate special pressures, sizes, and designs to be flexible on special needs in industries such as pharmaceuticals, energy, or chemical processing.

| يكتب | Description | التطبيقات |

| Horizontal Vessels | Positioned horizontally to maximize floor space. Used in space-limited environments like oil & gas. | Oil and gas, chemical processing |

| Vertical Vessels | Positioned upright to save floor space. Suitable for gravity-based separation. | Process industries requiring gravity separation |

| Cylindrical & Spherical Vessels | Cylindrical vessels for storage; spherical for higher-pressure environments. | Storage and high-pressure environments |

| Storage Pressure Vessels | Designed for storing liquids or gases under high pressure. | Chemical, energy, and storage industries |

| Process Pressure Vessels | Used in chemical processes and reactions under high pressure. | Pharmaceuticals, chemicals |

| Vacuum Vessels | Create a vacuum environment for sensitive processes or material handling. | Laboratories, chemical processes |

| Jacketed Pressure Vessels | Vessels with an outer layer to maintain or regulate temperature. | Food and pharmaceutical processing |

| ASME Certified Vessels | Vessels certified by the American Society of Mechanical Engineers ensure safety and quality standards. | High-pressure applications in various industries |

| Custom Pressure Vessels | Designed to meet specific operational requirements with tailored sizes, shapes, and pressure ratings. | Specialized industries such as pharmaceuticals and energy |

Benefits of Using Stainless Steel in Pressure Vessels

· Corrosion Resistance and Durability

Stainless steel shows high resistance to corrosion. This improves the life of the vessel and lowers maintenance expenses, which makes it best to be used in extreme environments such as chemical processing and oil storage.

· Strength and Structural Integrity

الفولاذ المقاوم للصدأ is highly tensile, which means that it can support internal pressure without loss of structural integrity. This renders the necessity of high-pressure applications in sectors such as the energy sector and pharmaceutical products.

· Hygienic Properties

The surface of stainless steel is smooth, and so it does not get contaminated. Cleaning and washing are easy and therefore suited to be used in pharmaceutical, food, and beverage firms where cleanliness is paramount.

· Economic Value

The strength of stainless steel decreases the replacement expenses and the downtime. Its lifespan is also long, which offers a greater return on investment than other materials used in the production of pressure vessels.

· Sustainability and Recyclability

Stainless steel is completely recyclable, which cuts the environmental effects. It also retains the properties of the recycled ones, which promotes green manufacturing and recycling of waste.

Uses & Applications Across Industries

· Chemical & Petrochemical

Pressure vessels made of stainless steel are a safe means of containing and processing high-pressure chemicals. They prevent corrosion and contamination, guaranteeing the integrity of sensitive substances in petrochemical plants.

· Oil & Gas

These vessels are required in the oil and gas sector to store and process oils and gases that are of very high density. They are resistant to corrosion, and this makes them very reliable in the long run in severe conditions.

· Pharmaceutical & Food Processing

Stainless steel pressure vessels play an important role in mixing, storage, and processing in the pharmaceutical and food sectors. They keep the environment hygienic and avoid contamination in the production.

· Energy & Power Generation

Stainless steel pressure vessels are implemented in the production of steam, storage, and heat exchange in energy production. They are strong and withstand high pressure and temperature, which guarantees efficiency and safety of operation.

· Water Treatment & Other Industrial Uses

Stainless steel pressure vessels are normally applied in water filtration and purification systems. They are very durable and corrosion-resistant, and hence have a long operation time in water treatment.

Key Considerations When Choosing a Stainless Steel Pressure Vessel

· Material Selection

Select the stainless steel grades depending on how the vessel will be used and in what environment. The most popular are 304 and 316, which are resistant to corrosion and tough enough to withstand hard environments.

· Design & Engineering Standards

Be sure to meet the industry standards, including the ASME and PED, to ensure the safety and performance. Independent design ensures that it does not fail under pressure and high temperatures.

· Safety and Inspection Requirements

Strict safety regulations of pressure vessels are to be observed. It also needs regular inspection and testing to identify areas of vulnerability so that the product can be safe and reliable even as time goes by.

· Operating Conditions

Take into account the pressure, temperature, and chemical compatibility of the ambience of the vessel. These have direct implications on the material choice, design, and long-term performance of the vessel.

· Fabricate ion & Welding Quality

The structuring of the vessel is guaranteed by the high quality of fabrication and welding. Welds that are perfectly made avoid leakage and increase the pressure vessel’s ability to resist high stress and temperature.

· Cost vs. Lifecycle Performance

Compare the cost with the performance and maintenance requirements in the long term. Quality vessels cost more in the initial stages, but are associated with reduced maintenance and replacement costs in the long term.

· Maintenance and Longevity

Select vessels that are easy to maintain and have a long life. Consistent maintenance, inspection, and repair of vessels are essential in making sure that the vessels operate consistently and safely during their lifetime.

Get Your Customized Stainless Steel Vessels from KDM Fabrication

We are KDM Steel, whose business is to give you the best customized stainless steel pressure vessel of the best quality, specifically what you need. Our vessels are of industry-standard strength, durability, and safety. To find the answer that is both stable and cost-effective, call us now and place an order for an individual quote.

الأسئلة الشائعة

What is the difference between a pressure vessel and a storage tank?

Pressure vessels are meant to contain liquids or gases under high pressure, whereas storage tanks are mainly meant to contain non-pressurized fluids or low-pressure conditions.

Can stainless steel pressure vessels be repaired if damaged?

Yes, it is possible to repair stainless steel pressure vessels using either welding or special methods, as long as the damage does not exceed limits that are allowed and does not affect structural integrity

What certifications should I look for?

Find out the certification of ASME, PED, and any industry-specific certification confirming the safety, quality, and regulation for the use in high-pressure applications.

How long do stainless steel pressure vessels last?

With proper maintenance, the stainless steel pressure vessels can survive 20-30 years or even longer based on the operation and maintenance practices.

Why is stainless steel often chosen over carbon steel for pressure vessels?

Stainless steel is the best choice in high-pressure applications because it has better corrosion resistance, greater strength, and performance in comparison to carbon steel.