In practical applications, enclosure plinths guarantee the safe installation, reliable operation and thermal management of the enclosure system. This article discusses the types, functions, and significance of the enclosure plinth. Hope this article will help you understand the importance of the enclosure plinth and provide effective guidance for your purchase.

What Is an Enclosure Plinth?

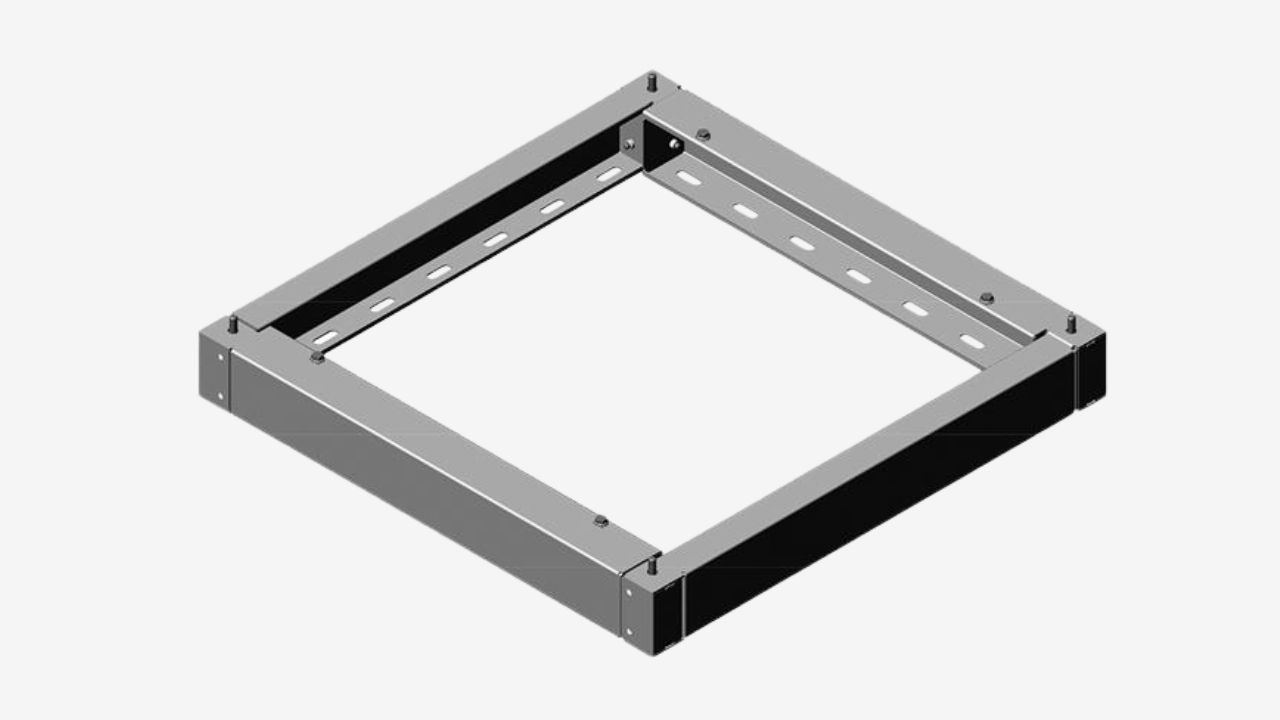

An enclosure plinth is a structural base installed beneath an electrical or industrial enclosure. It is used to support, elevate and protect the enclosure. Enclosure Plinths are typically used in electrical control panels, switch cabinets, automation enclosures and outdoor equipment enclosures. The plinth elevates the enclosure above the ground, which helps prevent damage caused by moisture, dust, water accumulation, corrosion and accidental impacts.

Besides physical support, the enclosure plinth provides bottom cable access, orderly cable routing, and space for improved ventilation. It can also evenly distribute the weight of the enclosure, improve structural stability and reduce the pressure on the enclosure frame.

Types of Enclosure Plinths

Enclosure plinths are usually classified according to materials, structure and design. For materials, enclosure plinths can be classified into steel plinths, stainless steel plinths, aluminum plinths, concrete plinths and polymer/GRP plinths. It can also be classified into many types according to the installation method. Here are the common types of enclosure plinths.

Solid Base Plinths

Solid base plinths are composed of a sturdy and completely sealed box or platform. If you require plinths with extremely strong protection capabilities, solid base plinths are your ideal choice.

Solid base plinths can provide excellent protection against dust, debris and accidental contact for your enclosure. You can use it in indoor or controlled environments and in situations where ventilation through the bottom is not required.

Modular Plinths

The modular plinths consist of independent components and can be assembled to fit different enclosure sizes. This flexible design allows you to adjust in width, depth and height. This is highly suitable for standardized enclosure systems. The modular plinths can be easily transported and installed.

Ventilated Plinths

The ventilated plinth is designed with ventilation holes on the side or front and rear, which can promote air circulation at the bottom of the enclosure. Improving ventilation helps with heat dissipation and reduces condensation inside the enclosure. You can install these plinths in high heat load or warm environments.

Adjustable Plinths

The adjustable plinth allows for height and level adjustment. It can keep the enclosure level and stable on uneven ground. The adjustable plinths can precisely adjust the height, improving installation accuracy and reducing structural stress.

The design of modern enclosure plinths is usually very complex. You can choose a multi-functional plinth that can meet your various needs at the same time. The specific type of plinth to be selected mainly depends on your core requirements.

Core Functions of Enclosure Plinths

Structural Support and Load Distribution

Plinth can distribute the concentrated load of large enclosures over a larger area to prevent local subsidence, cracking or damage to the floor. This also reduces stress on the enclosure frame and prevents deformation. This function is the most fundamental and essential feature of the enclosure plinths.

The sturdy and level plinths can verify that the enclosure does not shake or tilt. This is beneficial for maintaining the stable operation of the precision equipment inside the cabinet.

Protecting against Environmental Factors

By elevating the cabinets above the floor or ground, plinths prevent moisture intrusion, dust accumulation, and debris. This elevation is particularly important in outdoor or industrial environments. High-quality protective plinths help the enclosures achieve the specific تصنيف IP or NEMA standards as a whole, to meet the stringent requirements of specific industrial environments.

Cable Management and Entry

The plinths create a dedicated space for the entry and routing of the bottom cables. This makes sure that your power and signal cables can be securely and neatly connected to the enclosure. At the same time, it also guarantees the IP rating of the entire enclosure. The neatly arranged cables also prevent crushing and trampling, improving the safety of the working environment.

Ventilation and Thermal Management

If you have installed high-power consuming devices, enclosure plinths are an important component of the thermal management strategy.

The plinth design facilitates the airflow at the bottom of the enclosure, which is beneficial for heat dissipation and reducing internal condensation. Improving ventilation helps achieve a more stable operating temperature and extends the lifespan of electrical components. In modern data centers, the design of plinths needs to be matched with the closed cold/hot aisle solution to guarantee that cold air is precisely delivered to the required areas and to prevent the mixing of hot and cold air.

Improving Accessibility for Maintenance

The adjustable plinths enable engineers to level the cabinet, which is beneficial for bottom maintenance or equipment replacement. The modular plinths can also be replaced individually for individual components, which reduces your maintenance complexity and cost.

Importance of Enclosure Plinths in Practical Applications

Better Stability and Durability

Professional enclosure plinths can provide a sturdy and level base for the equipment. This fundamentally eliminates the vibration and stress conditions of the equipment, reducing mechanical wear and fatigue of electronic components.

Besides, the physical lifting and ventilation design isolates the equipment from moisture, corrosive liquids, conductive dust, etc. on the ground. These several factors have slowed down the corrosion of the enclosure body and the oxidation of the internal circuit boards. As a result, the overall lifespan of the equipment is extended, and the failure rate is greatly reduced.

Safety and Compliance

If you use enclosure plinths, heavy enclosures will not topple over during earthquakes, accidental impacts or when internal equipment slides. This can protect the safety of personnel on site. Integrated cable management can also prevent tripping and accidental electric shocks.

Most importantly, a well-sealed solid base plinth can prevent fire and smoke from spreading upward through floor gaps into the electrical enclosure. This can provide you with a certain fire barrier.

What’s more, in many regions and industries, the installation of equipment must comply with specific safety and construction regulations. The plinth is the fundamental component for seismic certification.

If your enclosure is installed in a data center or industrial environment, using a professional electrical plinth is the most direct and standardized approach to meet the auditing requirements for equipment installation, cable management, grounding, and heat dissipation.

Scalability and Baying Support

If you want to add more enclosures, the modular plinths can directly add modules to achieve seamless integration. You can arrange the enclosures in various ways, such as single cabinets or rows. This enables better adaptation to the dynamic changes in the server room layout. The convenience of scalability also reserves space and installation points for potential future addition of bottom equipment.

When multiple cabinets are placed side by side, the enclosure plinth guarantees that the ground of each enclosure is level and arranged neatly. This greatly optimizes airflow management and cable routing, and is the foundation for building high-performance enclosure clusters.

Reduced Downtime&Enhanced Efficiency

The plinths have improved accessibility, organization and security. These important features and advantages directly affect your operational costs and the continuity of your business.

The improvement in enclosure stability, environmental protection and heat dissipation optimization directly prevent sudden failures caused by overheating, moisture, vibration and other factors of equipment damage.

The operation and maintenance personnel can quickly locate the problem cable or equipment according to the clear cable identification and path. This helps to shorten your average repair time(MTTR). Besides, the adjustable design and modular components make maintenance more convenient.

Optimized airflow management can also reduce the energy consumption of your cooling system and improve power usage efficiency. Professional and stable installation enables you to adopt a higher-density equipment deployment method, safely accommodating more computing power within a limited space.

Application Cases of Enclosure Plinths

Data Centers and Server Enclosures

The common types of plinths used in these environments are adjustable plinth and ventilated plinth.

In such application environments, you need high load-bearing capacity and stability to protect the floor structure of the equipment. Heat dissipation management is also equally important in this type of environment. The ventilation plinths make sure that cold air is effectively introduced into the enclosure from the bottom, preventing the servers from overheating. Besides, neat wiring and ease of expansion are also very important.

Industrial Automation Control Panels

The main plinth application types include solid and modular pedestals.

In an industrial automated production environment, plinth elevates the cabinet to avoid the influence of flushing water, oil and dust. The plinth also provides a bottom cable entry for power and control cables connection. It also improves the stability of the cabinet under mechanical vibration. What’s more, the plinths help keep the IP protection level in harsh production environments.

Telecommunications and Outdoor Infrastructure

Most outdoor 5G base station cabinets and roadside optical cable junction boxes use high-level protective solid base plinths or special outdoor plinths. Such plinths are usually equipped with special sealing and anti-robbery designs.

When using the outdoor plinths, it mainly lifts the equipment off the ground to prevent water accumulation and accidental flooding from causing damage. Some outdoor plinths also incorporate insulation layers or ventilation and heat dissipation systems to cope with high temperatures in summer and low temperatures in winter. The sturdy design prevents the entire cabinet from being easily moved or stolen.

Energy and Public Utilities

For example, in environments such as substation control rooms and renewable energy inverter cabinets, you mainly use heavy-duty seismic plinths or ventilation and dust-proof plinths.

If you apply the plinth to critical power facilities, the plinth is an essential part of the overall seismic design. It guarantees that the control system does not fail during an earthquake. If you apply it to dusty or humid equipment rooms, the plinth can also protect sensitive monitoring and control systems. Besides, the electric plinth can also align high-voltage and low-voltage cables, keep safe spacing, and prevent interference and accidents.

Choosing the Right Enclosure Plinth

Access the Enclosure and Installation Environment

First, you need to consider the specifications of the equipment you need. You must first accurately measure the depth, width and height of the enclosure. Calculate the maximum total weight of the equipment. Then, you also need to consider what kind of layout you need.

Secondly, you also need to consider the conditions of the installation environment. If you install it in an indoor clean environment, solid base plinth and modular plinth are enough. However, if in an environment with high hygiene requirements or corrosive conditions, you should choose الفولاذ المقاوم للصدأ or non-metallic plinths. Generally, the more harsh the environment is, the more protective plinth you need to choose.

Next, you also need to consider the heat dissipation requirements of the enclosure. This requires you to assess the total heat generation of the devices inside the enclosure. You also need to estimate the number and type of cables in the cabinet, which is related to your wiring requirements. Then, you need to check whether the installation ground is level and whether there is a risk of earthquake. This is related to the type and standard of the plinth you choose.

Consider Material and Finish

All the above questions can determine the specific type of plinth you choose. After that, you also need to consider the material and finish you choose for your plinth.

Cold-rolled steel with طلاء مسحوق is the most common type of plinth. It has high cost-effectiveness and is suitable for most indoor environments.

You can choose stainless steel plinth for applications in environments with high hygiene requirements, high humidity or corrosive conditions. 316 stainless steel has a stronger corrosion resistance. The الألومنيوم is lighter in weight and has corrosion resistance, but it has a higher cost and lower load-bearing capacity.

Audit Quality and Compliance

Before making the purchase, you also need to check the quality of the sample, the spraying process, etc. This is related to the strength, safety and appearance of your plinth. If the plinth you customize or purchase has an earthquake resistance certification or IP rating, you need to check whether the certification is valid. The qualifications of the supplier should also be evaluated from multiple aspects to verify the quality of the plinth.

التعليمات

Are Enclosure Plinths Required by Standards or Regulations?

There are no mandatory requirements for plinth. However, electrical and industrial standards usually recommend or indirectly require the use of enclosure plinths to meet safety and environmental protection needs. In many installation environments, plinths help guarantee compliance with IP ratings and grounding rules.

What Is the Recommended Height of an Enclosure Plinth?

The recommended height of an enclosure plinth depends on the application, environment, and enclosure size. Typical plinth heights range from 100 mm to 300 mm. Outdoor or flood-prone areas may require taller plinths to guarantee adequate protection and cable clearance.

What Is the Difference Between an Open Plinth and a Closed Plinth?

The open plinth adopts an open frame structure, which facilitates air circulation and cable connection. It is suitable for indoor or controlled environments. The closed plinth is completely sealed and can better resist dust, water and pest invasions. It is usually used in outdoor or harsh environments.

Can an Enclosure be Installed Without a Plinth?

Yes. You can customize the enclosure plinth according to height, material, load-bearing capacity, surface treatment and installation configuration. Customized plinths are often used for non-standard cabinets, heavy equipment, or to meet specific environmental and regulatory requirements.

Final Thought

Proper plinth selection can improve safety, keep enclosure seal and protection grade, and extend the service life of electrical equipment. KDM is a custom manufacturer of electrical enclosures. We can provide you with comprehensive custom production services. Our years of production experience and multiple certifications are the reasons why you can trust us. اتصل بنا to get your customized solutions.