Electrical protection and current management are important to solar power systems. The photovoltaic combiner box plays a key role in this respect,by providing centralized protection and simplifying wiring. This article discusses the functions, types and selection guidelines of PV combiner boxes. Hope this article helps you choose the appropriate PV combiner box for your solar system.

What Is a Photovoltaic Combiner Box?

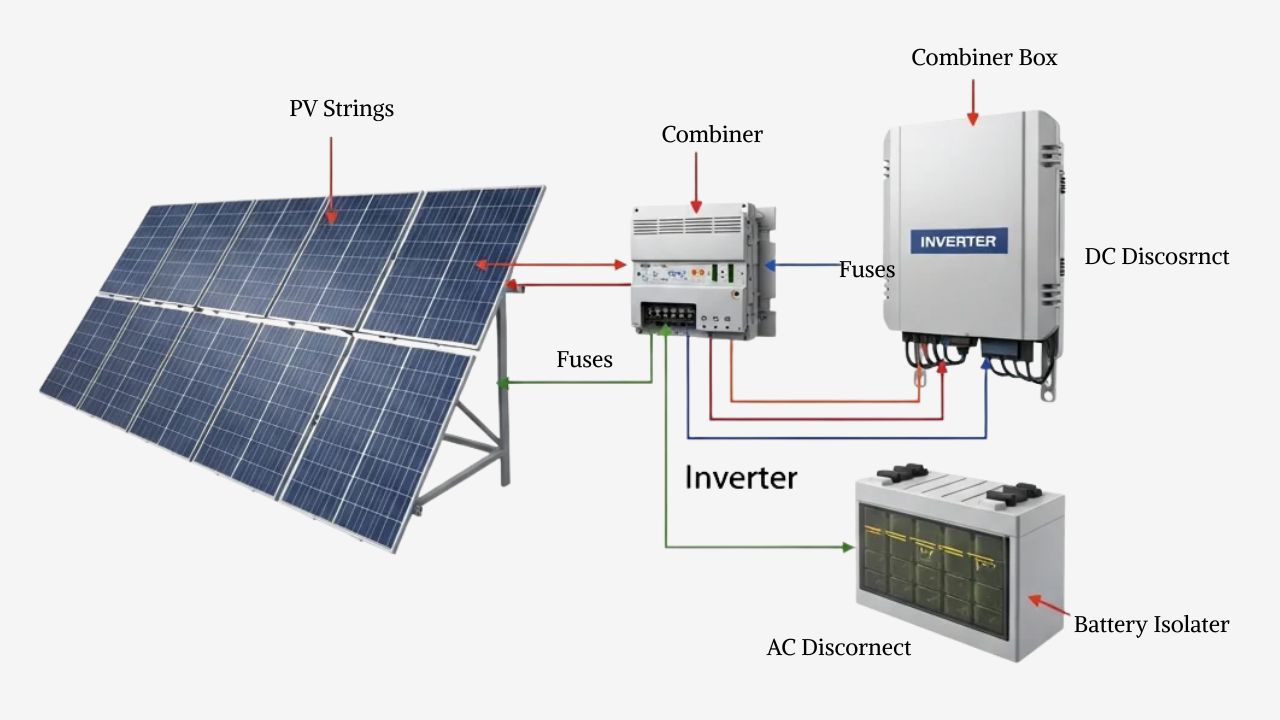

The photovoltaic (PV) combiner box can also be called a solar combiner box or array combiner box. It is a key electrical device on the DC side of the photovoltaic power generation system. The photovoltaic combiner box is usually installed between the photovoltaic modules and the inverter.

Its main function is to parallelly combine the solar panel strings(pv strings) formed by the series connection of multiple photovoltaic modules for centralized output. This can reduce the number of inverter DC cables, simplify the system structure, more conducive to your monitoring and maintenance.

Functions of a PV Combiner Box

Current Aggregation(Combining Multiple PV Strings)

A PV power system consists of thousands of PV string arrays. If you directly connect each string to the inverter, it will result in a large number of cables and messy wiring. And this will also greatly increase costs and the risk of electrical failures.

However, the solar combiner box can aggregate the cables into a main output cable that connects to the inverter. This can help you simplify the system structure and reduce cable and construction costs. It also improves the aesthetics and maintainability of your system.

Besides, the solar combiner box is equipped with standard input/output terminal blocks, DC busbars, etc. Standardized electrical interfaces can greatly guarantee the safety and reliability of your cable connections. And this also complies with electrical specifications.

Electrical Protection and Safety Assurance

Overcurrent and Short-Circuit Protection: DC fuses or DC miniature circuit breakers will cut off the faulty circuit when reverse current is generated due to internal short circuits or other reasons within the string. This can help you prevent the fault from expanding and guarantee the normal power generation of other strings.

Lightning and Surge Protection: Photovoltaic systems are prone to induced lightning strikes or surge impacts from the power grid. The surge protection device (SPD) inside the PV combiner box can discharge overvoltage to the ground within nanoseconds. It can protect your inverters and equipment from being damaged by breakdown.

DC Side Segmentation and Isolation: The main output terminal is usually equipped with a DC disconnect switch or a load switch. This provides you with a visible and physical disconnect point. When you service the inverter or inspect the system, you can safely cut off the DC power output by the combiner box to guarantee your operational safety.

Monitoring and Fault Detection

Collecting Detailed Data: Current sensors and voltage sampling circuits can help you monitor the input current of each string in real time (the most important parameter), the total output voltage, total current and power after the current is aggregated, the internal temperature of the box, and the status of the circuit breaker, etc.

Fault Location and Alerting: The system can detect and locate abnormal strings through each string’s current comparison. What’s more, it can also determine the fault type in combination with real-time data. If the PV combiner box detects a drop in current, deterioration of the SPD, etc., it can carry out preventive maintenance to prevent the fault from expanding.

Upload Data: The collected data can be uploaded to inverters, data collectors, or directly to the cloud monitoring platform. You can monitor the operation status of all PV combiner boxes. And you can generate reports such as power generation analysis.

Reliable Physical Protection

The PV combiner box usually uses a high-level protective enclosure(usually IP65). It can prevent dust and water, and is capable of withstanding harsh outdoor conditions such as rain, snow, and sandstorms. The enclosure also prevents accidental contact by people. A well-designed enclosure can also help the internal components dissipate heat more effectively.

Benefits of Using a PV Combiner Box

Reduce Cable and Construction Costs: Simplifying the number of output cables can directly save DC cable procurement costs, bridge and labor costs. This brings considerable economic benefits.

Optimize System Structure: Centralize the string interface to make the wiring structure of the DC side of the solar power station clear and well-organized. This is beneficial for your later line inspection and upgrade.

Precise Operation and Maintenance: Real-time monitoring and precise positioning can greatly improve processing efficiency. Preventive maintenance effectively helps you avoid sudden malfunctions. The collection of key data can help you comprehensively analyze the performance of the PV power station.

High Environmental Adaptability: The high protection level of the enclosure provides a stable operating environment for the internal components. This extends the service life of the devices and reduces unexpected failures caused by environmental factors.

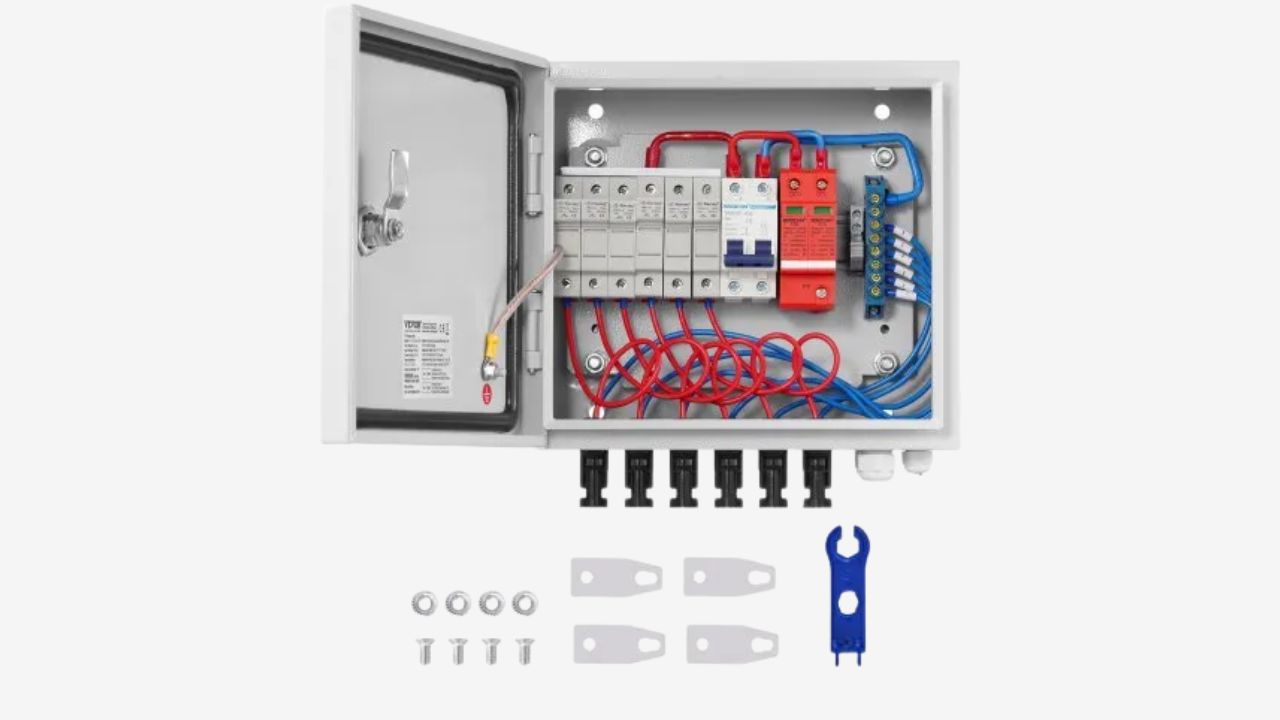

Main Components of PV Combiner Box

PV String Fuses

The PV string fuses are used for overcurrent protection for each PV string. They protect the cables and PV modules from damage caused by reverse current or short circuits. It is also able to prevent the fault current from flowing into the fault string from other parallel strings.

DC Circuit Breakers

The DC circuit breaker has manual/automatic circuit protection functions. When there is overcurrent or a short circuit, it can automatically trip to protect the circuit. Besides, you can also manually disconnect the DC circuit breaker for maintenance. The DC circuit breaker improves the maintenance convenience and system operability.

Surge Protection Devices(SPD)

SPD is mainly used to prevent transient overvoltage. It can protect DC equipment from the effects of lightning strikes and switching surges. SPD can also limit surge voltage and safely ground the excess voltage. It can prevent inverter failures and system shutdown caused by surges.

DC Disconnect Switch

The DC disconnect switch has the function of safe electrical isolation. It supports complete disconnection of PV arrays from the inverter. It is usually used during your maintenance, emergency shutdown, or repair operations.

قضبان التوصيل

It is typically used to collect the currents from multiple strings and output the combined current. This design improves efficiency and the reliability of the system. It also reduces the complexity of the wiring inside the PV combiner box.

كتل طرفية

The terminal block provides reliable connection points for the incoming and outgoing cables. The glands of the cable provide good shocking absorption and sealing.

Monitoring Module(Smart Combiner Box)

The monitoring module mainly monitors the current, voltage and temperature of the strings. Besides, it can also detect string faults or فتيل failures, etc. The detected data will be uploaded to the platform for your analysis.

حاوية

The PV combiner box is usually made of stainless steel, aluminum or flame-retardant plastic. The enclosure mainly provides environmental and mechanical protection for the internal components. A sturdy enclosure can guarantee the long-term service life of the internal components in harsh environments.

Types of the PV Combiner Box

حسب الجهد

600V DC PV Combiner Box/1000V DC PV Combiner Box

This type of photovoltaic combiner box is technologically mature, has a complete industrial chain, and has relatively low costs. The 1000V solar combiner box is currently the mainstream choice for industrial and commercial distributed power generation and some ground-based power stations. They are mostly applied in some early-built ground-based photovoltaic power stations or small and medium-sized industrial and commercial rooftops.

1500V DC PV Combiner Box

It can substantially reduce cable losses and lower system costs by increasing voltage and reducing current. You can apply it to large-scale ground-based photovoltaic power stations and photovoltaic bases.

By Number of Input Strings

Low-Input PV Combiner Boxes(2-4 Strings)

The 2-in-1-out PV combiner box and the 4-in-1-out PV combiner box are common low-input combiner boxes. These types of combiner boxes are easier to install, have lower costs, and require much less space.They are mainly applied in PV systems on residential rooftops, small hybrid solar systems or string inverter systems with fewer inputs.

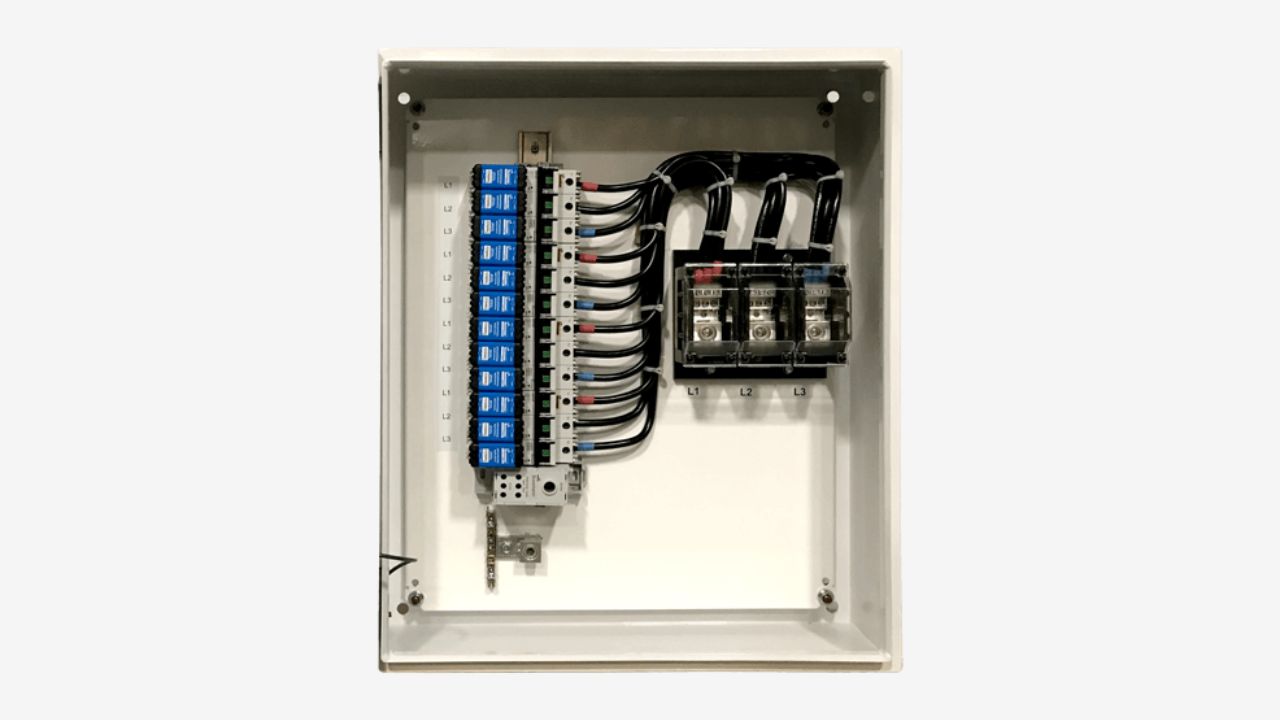

Medium-Input Combiner Boxes(6-12 Strings)

6-in-1-out PV combiner boxes, 8-in-out PV combiner boxes and 12-in-1-out PV combiner boxes are common examples. They have a medium current handling capability. Besides, they can reduce cable length and power loss, and achieve a balance between scalability and cost. You can apply them to commercial or industrial rooftop photovoltaic systems, medium-sized ground solar power stations, etc.

High-Input PV Combiner Boxes(16-24 Strings)

16-in-1-out PV combiner boxes,20-in-1-out PV combiner boxes and 24-in-1-out PV combiner boxes are common examples. They are characterized by high current capacity. Most of these combiner boxes are equipped with monitoring modules. You can use them in outdoor and harsh environments such as large-scale solar power stations and large ground photovoltaic arrays.

Super High-input or Customized Combiner Boxes

This type of photovoltaic combiner box usually has 32 strings or even higher. These combiner boxes are usually customized according to the project and are equipped with advanced monitoring and communication systems. They are commonly used in large-scale solar power farms, desert or high-altitude photovoltaic projects, and projects that require SCADA integration.

By Function

Standard PV Combiner Boxes

The standard photovoltaic combiner box only has the most core functions of current collection, overcurrent protection and lightning protection. You can apply it in scenarios with low operation and maintenance requirements, limited budget, or small-scale projects.

Smart/Monitored PV Combiner Box

It integrates a string-level monitoring module on the basis of the former. It can monitor the current, voltage and power of each circuit in real time. It also has the functions of fault alarm and location. It is the standard equipment for medium-sized and large industrial and commercial projects and power station-level projects.

How a PV Combiner Box Works in a PV System

The purposes of the PV combiner box in a PV system can be summarized into three core steps: combining, protection, and monitoring (smart PV combiner box).

Combining

The photovoltaic modules are connected in series to form string groups with a higher DC voltage. The positive and negative DC cables of each string group are connected to the corresponding input terminals of the combiner box. The combiner box can also be divided into 4 string PV combiner box, 6 string PV combiner box, 8 string PV combiner box and 12 string combiner box, etc., according to the input terminals.

Inside the solar combiner box, the positive poles of all the input string circuits are connected through a DC fuse and then are paralleled to a common busbar. All the negative poles are also paralleled to a common negative busbar. Finally, the bus will lead to a pair of main output cables, leading to the DC input section of the inverter.

حماية

Overcurrent protection: The DC fuse will melt rapidly when a string fails or a reverse current occurs. This approach isolates the faulty string to prevent it from affecting other normal strings and the inverter.

Surge Protection: SPD is used to protect the downstream equipment from transient overvoltage caused by lightning induction or switching operation.

Monitoring

The intelligent photovoltaic combiner box is equipped with a data collection module, which can monitor the DC current of the string, the total DC voltage, total current, the temperature inside the box, and the fuse status in real time. These data will be uploaded to the monitoring platform or the inverter. You can also precisely locate the specific faulty string remotely. Your operation efficiency has also been improved.

How to Choose A Proper PV Combiner Box

Matching the Main Electrical Parameter

You need to choose between a 1000V or 1500V architecture based on the design of your photovoltaic system. You can directly select the photovoltaic combiner box corresponding to the voltage rating. The 1500V system has higher requirements for the insulation rating of components and is currently the mainstream choice for large-scale power plants.

Next, you can choose to input the number of strings that is equal to or slightly more than the total number of string groups. For example, if you have 20 strings, you can choose 20 or 22 strings. The extra strings are reserved for future expansion.

You also need to take into account the maximum short-circuit current of the selected photovoltaic modules under extreme conditions, and consider a safety margin of at least 1.25 times.

To prevent circuit overload, the rated current of the main circuit breaker in the busbar box and the current-carrying capacity of the internal busbar must be greater than or equal to the sum of the maximum working currents of all strings.

Consider Monitoring Needs

Based on your system design requirements, you need to choose whether to select the intelligent monitoring solar combiner box . The standard photovoltaic combiner box is more suitable for small-scale projects with limited budgets, small system sizes, or no need for detailed operation and maintenance.

If you apply it in industry, commerce and power stations, the smart combiner box is your best choice.

Besides, you also need to consider whether you require advanced functions. If your project is based on mandatory safety regulations, you should choose a combiner box with DC arc detection and rapid shutdown.

Environment Conditions

Depending on your installation environment, you need to select the right protection rating. For outdoor installations, IP65 is the basic requirement. For coastal or rainy environments, you can choose IP66.

For the enclosure material, galvanized aluminum steel is a common choice, which has a high cost-effectiveness and good corrosion resistance. Stainless steel is more suitable for high-corrosion environments, but it is more expensive.

Besides, you should check if the box has ventilation holes or cooling fans. If your system is installed densely and carries high current, thermal management is indispensable.

Finally, based on your project plan, choose the right installation method, such as wall-mounted, pole-mounted, or floor-standing enclosure.

Safety and Certification Requirements

Apart from the functions of the combiner box, you should also check whether the product has been certified by authoritative institutions, such as CE in the EU or UL in the US. When buying, you should give priority to buying a brand that has a good reputation in the photovoltaic field. You need to confirm the reliability, consistency and availability of after-sales service of the product.

التعليمات

What Is the Difference Between a Combiner Box and the DC Input Terminals inside An Inverter?

The purpose of the combiner box is to provide independent protection and monitoring for each string. The combiner box can precisely isolate and protect the inverter when a fault occurs. While the inverter terminals are merely a general connection point. They cannot independently manage and protect each wire.

Do Small-Scale Residential Photovoltaic Systems also Require Independent Combiner Boxes?

Generally, it is not necessary. Most modern residential photovoltaic systems can directly connect the string arrays to the inverter. This is because residential systems are relatively small in size, and the integrated protection of the inverter has replaced the basic protection functions of the independent combiner box. What’s more, adding independent devices is not cost-effective for small systems.

What Are the Environmental Requirements for Installing a PV Combiner Box?

The PV combiner box should be installed in a well-ventilated, cool and dry place. And it must be kept away from flammable and explosive materials. The installation height and surrounding space of it should be convenient for observation, operation and maintenance. And the enclosure material must match the installation environment conditions.

Is the Surge Protection Function of a PV Combiner Box Permanent?

No. SPD is a consumable protective device. It absorbs and dissipates voltage surge energy by consuming its internal components. Therefore, you need to check its status regularly and replace it in time.

Final Thought

KDM can provide you with reliable and consistent combiner boxes. We have many years of experience in electrical enclosure custom production and have obtained a number of certifications. We use high-quality raw materials and advanced production technologies. If you have any requirements for custom electrical enclosures, we can respond promptly and give a personalized custom solution to you. Please feel free to اتصل بنا.