Electrical Enclosure Safety

What is Electrical Enclosure Safety?

It is a set of guidelines and mechanisms that protect enclosure and its content, alongside users from potential factors that can cause damage, destruction, malfunction, or injury.

Ideally, electrical enclosures will:

- Protect its content from harsh environmental conditions

- By incorporating certain mechanisms, such as enclosure cooling systems they protect components from overheating

- Protect technicians or users from the propagation of explosion and electric shock

- Prevents unauthorized persons from accessing the components in the electrical enclosure

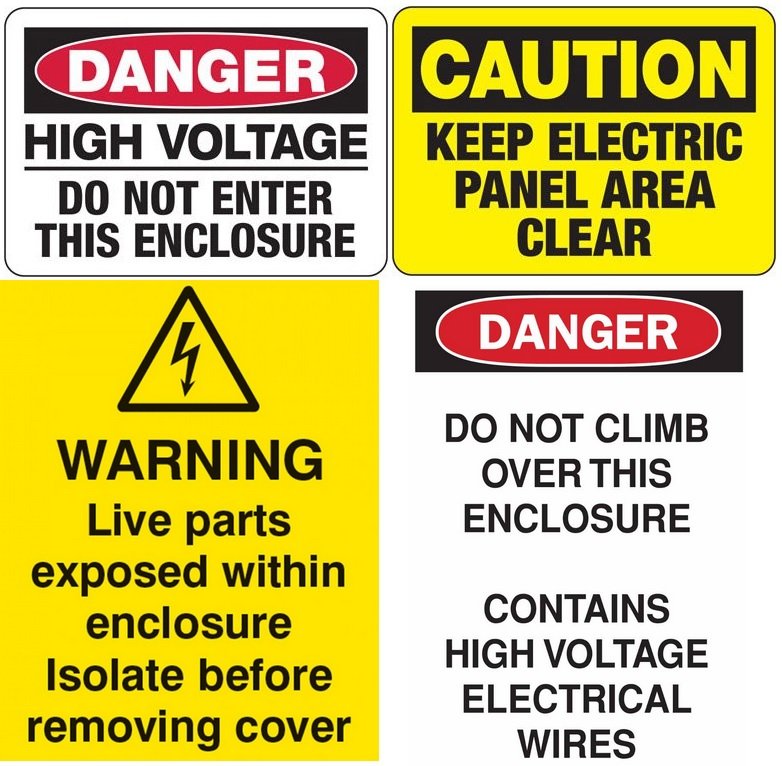

What are Electrical Enclosure Safety Signs?

Electrical enclosure safety signs are messages or information on the electrical enclosure to:

i. Indicate danger – they are for situations where serious injury or death may occur.

ii. Act as a warning – although the electrical enclosure safety sign indicates situations where serious injury or death may occur, the risk is not severe.

iii. Show caution – here, the risk is moderate, and they are mainly used to express unacceptable practices around the electrical enclosures.

Generally, the electrical enclosure safety signs are designed to warn and caution users from accessing, touching, handling, or being close to electrical cabinets without:

- Special permission

- Technical expertise and experience

- Safety wear

Electrical enclosure safety signs

As you can see, the electrical enclosure safety signs have different messages and designs.

It will depend on the message you intend to communicate.

Also, different states or regions have varying electrical enclosure safety signs rules and regulations.

For example, in the U.S.A., the signs must conform to the NFPA 79 standard and ANSI Z535 standards.

Remember, for a better electrical enclosure safety, the signs must be where someone can easily see and read the information.

Enclosure safety sign – Photo courtesy: RITHERDON

Are there Specific Requirements that will Guarantee Electrical Enclosure Safety?

Certainly, there is quite a number.

Here are some of the key aspects that will ensure electrical enclosure safety:

i. Material for Electrical Enclosure

You can choose electrical enclosure made from stainless steel, aluminum, galvanized steel or polycarbonate.

Whether you’re choosing electrical enclosure panel sides or insulation material, it must be high-quality material.

ii. Electrical Enclosure Mounting Option

There are free-standing electrical enclosures, wall mount electrical enclosure, or floor mount electrical enclosures.

In each case, the enclosure should have a reliable, strong, and durable mounting option that can secure it in the exact position.

It doesn’t matter whether you will mount electrical enclosure horizontally, vertically or in any other position.

iii. Degree of Protection

Whether you are using electrical enclosure outdoors or indoors, it must provide a specific degree of protection.

It should protect the enclosure content from a range of environmental conditions such as water, excess temperature, corrosive gases, dirt, and dust ingress.

Therefore, you should choose IP enclosures or NEMA enclosures.

iv. Consider Climate Control

Protection from freezing or overheating is an important electrical enclosure safety procedure.

For instance, electrical enclosure overheating may result in:

- Premature component failure

- Fire outbreak

On the other hand, accumulation of moisture may cause rusting.

Depending on where you will install the electrical enclosure, choose better enclosure temperature control mechanisms such as air conditioners, filter fans, etc.

In addition to these, you should consider the size and the ability to customize the electrical enclosure without compromising its safety features.

How Does KDM Guarantee Electrical Enclosure Safety?

KDM follows strict quality standards and regulations.

It begins from choosing high-quality material, regular quality inspection to using precise fabrication and machining techniques.

All our electrical enclosures must conform to:

At KDM, we adhere to the design requirements recommendations by the International Electrotechnical Commission (IEC), and the Institute of Electrical and Electronics Engineers (IEEE).

It is for this reason that KDM designs enclosures for a high level of resilience, with the best safety features.

What is Electrical Enclosure?

It is a housing or cabinet, specially fabricated and machined, according to NEMA and IP ratings, to house and protects electrical accessories.

It protects electrical equipment and related accessories from various environmental conditions.

Besides, the electrical enclosure also prevents users from accessing the electrical enclosures, hence ensuring safety.

Figure 3 Electrical enclosure

Does Electrical Enclosure Standards Affect Safety?

Yes, they do.

For instance, complying with the UL, RoHS, CE, IP, and NEMA standards produce high quality and reliable enclosures.

They are enclosures that can protect their content and users.

Are Door Locks and Latches Part of Electrical Enclosure Safety Systems?

Yes.

Enclosure door locks and latches play an integral role in electrical cabinet safety.

Locking mechanism prevents unauthorized personnel from accessing the electrical enclosure content.

Therefore, lockable electrical enclosures provide the necessary protection and safety.

Door locking mechanism

Which Electrical Enclosure Design Features Guarantee Safety?

i. Enclosure door locking mechanism – prevents unauthorized access to the enclosure

ii. Conforming to the necessary design standards such as NEMA and IP rating requirement

iii. Adopting continuous hinges and concealed hinges for the enclosure – it makes it virtually impossible to break into the electrical enclosure

iv. Installing the necessary electrical enclosure temperature control mechanisms

v. Sloped top electrical enclosures for easy draining of water

vi. Robust and high-quality cable management system

Apart from these features, you should buy the electrical enclosures from a reputable manufacturer.

Such manufacturers adhere to quality design standards that ensure electrical enclosure safety.

What is the High Voltage Safety Enclosure?

It is an enclosure specifically designed to protect both equipment and technicians (users) from high voltages or electric shock.

High voltage safety enclosures feature a mandatory grounding system and an efficient earthing mechanism.

Besides, interlocking door system and special construction is also a priority.

Why is NEMA Rating Important in Electrical Enclosure Safety?

Understanding the NEMA rating will help you to:

- Ensure the enclosure is compatible with a specific environment where you intend to use it

- Know whether the enclosure meets the desired functioning standards and requirement

- Understand the electrical enclosure product safety guidelines

Depending on your unique performance requirements, you can choose the NEMA enclosure designed for:

i. Indoor applications – they include NEMA enclosure types 1, 2, 5, 12, 12K, & 13

ii. Hazardous environment, where you can choose NEMA enclosure types 7 & 9.

iii. Both indoor and outdoor applications which include NEMA enclosure types 3, 3X, 3R, 3RX, 3S, 3SX, 4, 4X, 6, & 6P

Remember, the latest revision of the NEMA rating is the NEMA 250-2018.

It focuses on electrical enclosures with a maximum of 1000 volts.

KDM Provides Which Electrical Enclosure Cabinet Safety Accessories?

At KDM, we offer enclosure locking systems and temperature control equipment.

If you want enclosure safety signs and alarms, we can also make some for you.

Also, our technical team offers free consultation on electrical enclosure safety.

Contact us today for all your inquiries on electrical enclosure safety.

Which Industries Does KDM Serve?

Our NEMA, UL, CE, and IP rated electrical enclosures are designed for all industries such as mining, power generation, power distribution, food processing, etc.

KDM electrical enclosures can suit any environment.

Tell us what your requirements are – KDM will fabricate and machine the exact electrical enclosure for you.

KDM Manufactures which Types of Electrical Enclosure Cabinet?

KDM manufactures all types of electrical enclosures from standard to custom designs.

Whether you need a freestanding, wall mount, floor mount, or modular electrical enclosures, KDM offers the best prices.

All our electrical enclosure manufacturing follows a strict quality inspection and standard compliance.

How Soon Can KDM Delivery Electrical Enclosures?

It will depend on whether you want standard or custom electrical enclosures.

Even for standard designs, KDM technical team will provide all the necessary drawings within a day.

Our sample will be ready within three days.

Talk to us today for all your electrical enclosure solutions with robust safety systems.